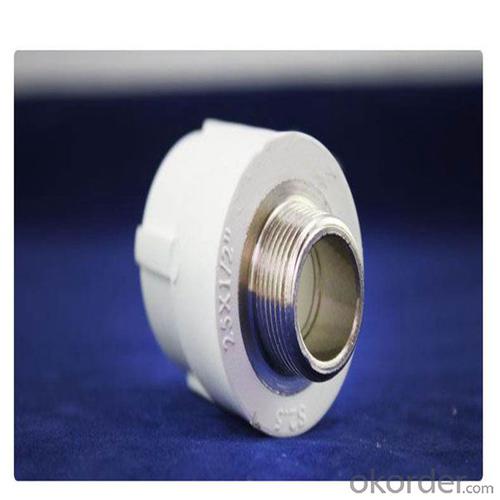

Barbed Plastic Pipe Fittings for China PP-R Pipe Coupling in Landscape Irrigation and Drainage Systems

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview:

1.It is used in industrial fields, agriculture and irrigation.

2.Beauty appearance.

3.Thermal insulation and energy saving.

4.Easy installation

5.excellent heat resistance and pressure resistance

6.affordable price

Why choose us?

(1) Professional factory: We are manufacturer, specializing in manufacturing multilayer PP-R, PE pipe and PP-R, PE pipe fittings for more than13 years, our price is competitive with high quality. And we can delivery product in quick way.

(2) Sample: We can send samples out in 3 days, but the express charge usually paid by your side, but the fee will be rebound when we have formal order.

(3) Rapid response to your needs: We will be answer within 24 hours. Welcome to contact with us if you have any problems. We are looking to cooperating with you.

(4) We hope we can establish long-term and mutual benefit business relation with you. If you have any problem, please kindly feel free to contact me. I will try the best to help you!

Product Applications:

1.Distribution for cool and hot water

2.Duct for drinkable water system

3.Pipes for kinds of high-temperature and low-temperature heating system

4.Pipes for heating and coolling settings in solar energy system

5.Connecting pipe for air conditioner

Product Description

Product Show

FAQ

Q: How do you guarantee the quality of your product?

A: Every process will be checked by responsible QC which insures every product's quality.

Q: How much is your delivery time?

A: Normally within 30 days of receipt of LC original or prepayment, but mostly according to the specific requirements or the quantity

Q: I need sample, could you support?

A: We can supply you with the sample for free, but the delivery charges will be covered by our customers. For avoiding the misunderstanding, it is appreciated if you can provide the International Express Account for Freight Collect. Also you can have a visit to us, welcome to CNBM!

- Q: How do you connect plastic pipe fittings to pipes?

- To connect plastic pipe fittings to pipes, you typically follow a few simple steps. First, ensure that both the fittings and pipes are clean and free from any debris. Then, apply a primer to the outside of the pipe and the inside of the fitting to help with adhesion. Next, apply a generous amount of solvent cement to both the pipe and fitting, ensuring complete coverage. Finally, quickly and firmly push the pipe into the fitting, giving it a slight twist to ensure a proper seal. Allow sufficient time for the cement to dry and create a secure bond before using or applying pressure to the system.

- Q: PE is the hot melt?

- 1. When using this method, the hot melt butt welding machine is adopted, and the main operation steps are as follows:After the butt welding machine has been debugged, put the pipe to be placed on the welding jig and clamp;The cleaning pipe end to be connected and connected with two end milling cutter alignment docking, the displacement is not greater than the pipe wall thickness of 10%:When the temperature of the heating plate reaches the set temperature, put it on the heating plate:After heating, take out the heating plate, quickly start the oil pump pressure, join the two pipe heating surface, and step up to the welding pressure, keep pressure and cool down:After cooling to the specified time, open the clamp and remove the pipe from the rack, observe the roll edge, determine the quality of the connection, and complete the connection.2. Check the quality of hot melt butt jointThe determination of the quality of hot melt butt welding is still mainly concerned with nondestructive appearance inspection of welding roll edges. Usually includes edge geometry and cutting edge visual inspection, the edge to behind the buckling to prove that connected with no lack of fusion check.Ultrasonic testing and X ray examination have been applied abroad.Destructive detection. Tensile test, bending test and tensile creep test are carried out at the interface respectively.3, hot melt docking notes:The procedures for the use of the docking machines and the matters needing attention shall be observed;Operators must wear gloves, wear overalls, do a good job of self-protection, to avoid electric shocks or burns;Heating the surface of the board, and the connecting ends should be kept clean:Docking pressure should be adjusted to the actual needs of the site:Polyethylene pipes shall not be heated by open flame;The welding interface to protect from sand and rain hit.

- Q: TTP-PESI hole net steel belt composite pipe fittings need to be taken?

- The connection of the hole net, the steel band and the composite plastic pipe can be made by flange connection, and also can be conveniently, quickly and safely welded by sleeve welding. The electric welding is connected with an electric heating element arranged in the pipeline, and the plastic of the inner wall of the pipe sleeve and the outer wall of the pipe (pipe fittings) is melted and cooled after being electrified to generate heat. The joint strength is high, the connecting force of more than 20000 kilograms of pipes and fittings, no leaks and other defects.

- Q: Are plastic pipe fittings UV resistant?

- Yes, plastic pipe fittings can be UV resistant. Many plastic pipe fittings are manufactured with UV stabilizers or additives that help protect them from the damaging effects of ultraviolet (UV) radiation. These additives enhance the durability and longevity of the fittings when exposed to sunlight or outdoor conditions. However, the level of UV resistance may vary depending on the specific type and quality of the plastic material used in the fittings.

- Q: Are plastic pipe fittings resistant to solvents and chemicals?

- Yes, plastic pipe fittings are generally resistant to solvents and chemicals.

- Q: Are the elbow and three - pipe fittings installed in the water supply and drainage pipes included?

- Indoor and outdoor plastic water supply pipe (hot melt connection) project, the pipeline joint parts are the same way of plastic pipe is connected with the pipeline, including various types of steel (copper) plastic conversion parts, such as other materials fee, the remaining unchanged.

- Q: Are plastic pipe fittings suitable for desalination plants?

- Yes, plastic pipe fittings are suitable for desalination plants. Plastic fittings are corrosion-resistant, lightweight, and durable, making them ideal for use in desalination plants where there is constant exposure to saltwater. Additionally, plastic fittings are easy to install, maintain, and have a longer lifespan compared to traditional metal fittings.

- Q: How do you select the right plastic pipe fittings for a specific application?

- To select the right plastic pipe fittings for a specific application, several factors need to be considered. First, you should determine the type of plastic pipe you are using, such as PVC, CPVC, or PEX, as each has different characteristics and compatibility requirements. Next, consider the intended use and environment of the application, including factors like temperature, pressure, and chemical compatibility. It is essential to ensure that the fittings are designed to handle the specific conditions of your application. Additionally, consider the fitting size and connection type, ensuring they match the pipe and other components you are using. Consulting with experts or referring to industry standards can also provide valuable guidance in selecting the appropriate plastic pipe fittings for your needs.

- Q: Are plastic pipe fittings resistant to organic solvents?

- Yes, plastic pipe fittings are generally resistant to organic solvents.

- Q: How to connect the wire mesh, steel tape and plastic composite pipe?

- Welding connection fittings using internal heating pipe fittings with inner plastic outer plastic melt, the pipes and fittings reliably connected together, but in order to ensure the whole pipeline system and under the same pressure, electric melting pipe is usually adopted in the production of Steel Lining Reinforced way.

Send your message to us

Barbed Plastic Pipe Fittings for China PP-R Pipe Coupling in Landscape Irrigation and Drainage Systems

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords