Threaded Plastic Pipe Fittings - China PP-R Equal Tee Fittings for Industrial Applications

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Overview

1) Cold / hot water supply facilities for public buildings

2) Food, chemical, electronic industry pipeline networks; Such as Pipeline networks for transporting all kinds of corrosive liquids

3) Drinking water production system pipeline networks; Such as Pure water and mineral water

4) Air conditioning facility pipelines

5) Compressed gas pipeline networks for industry

6) Pipeline networks for swimming pools

7) Pipeline networks for solar energy facilities

8) Agriculture and garden production transporting systems

Our Advantages:

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Recyclable, environment-friendly, accords with GBM standards

Product Description

Product name | Size | Weight | Pack |

Equal tee | (Gram/m) | (m/pack) | |

T16 | 12.5 | 1300 | |

T20 | 19.4 | 800 | |

T25 | 30.5 | 450 | |

T32 | 48.2 | 260 | |

T40 | 90.8 | 150 | |

T50 | 142.5 | 106 | |

T63 | 275.3 | 54 | |

T75 | 515.0 | 30 | |

T90 | 712.0 | 18 | |

T110 | 1082.0 | 12 | |

T125 | 1544.0 | 8 | |

T160 | 2531.0 | 4 |

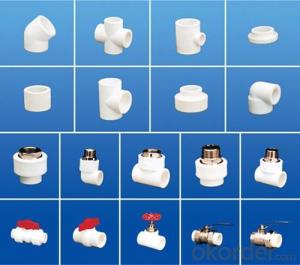

Product Show

Our Services

1. OEM Manufacturing welcome: Product, Package...

2. Sample order

3. We will reply you for your inquiry in 24 hours.

4. after sending, we will track the products for you once every two days, until you get the products. When you got the

goods, test them, and give me a feedback.If you have any questions about the problem, contact with us, we will offer

the solve way for you.

- Q: How do plastic pipe fittings compare to fiberglass fittings?

- Plastic pipe fittings are generally more affordable and readily available compared to fiberglass fittings. However, fiberglass fittings offer superior strength, durability, and resistance to corrosion and chemicals. They are also lightweight and have better thermal insulation properties. Ultimately, the choice between plastic and fiberglass fittings depends on the specific requirements and intended use of the fittings.

- Q: Can plastic pipe fittings be used for hot water applications?

- Yes, plastic pipe fittings can be used for hot water applications. However, it is important to choose fittings that are specifically designed and rated for use with hot water to ensure they can withstand the temperature and pressure requirements of the system.

- Q: What types of plastic are commonly used for pipe fittings?

- Some common types of plastic used for pipe fittings include PVC (polyvinyl chloride), CPVC (chlorinated polyvinyl chloride), and PEX (cross-linked polyethylene).

- Q: Can plastic pipe fittings be used for gas piping?

- No, plastic pipe fittings should not be used for gas piping. Gas piping requires materials that are specifically designed and approved for gas applications, such as steel or copper fittings, due to the safety risks associated with gas leaks and potential fire hazards.

- Q: Do plastic pipe fittings require any special tools for installation?

- Yes, plastic pipe fittings require special tools for installation. Common tools include pipe cutters, deburring tools, and crimping or compression tools, depending on the type of fitting being used. These tools are necessary to ensure a proper and secure connection between the pipes and fittings, as well as to prevent leaks and maintain the integrity of the plumbing system.

- Q: Can plastic pipe fittings be used in culvert systems?

- Yes, plastic pipe fittings can be used in culvert systems. Plastic pipe fittings are commonly used in culvert systems due to their durability, corrosion resistance, and ease of installation. They are lightweight, cost-effective, and can withstand the pressures and environmental conditions typically found in culvert systems. Additionally, plastic pipe fittings offer a variety of options to accommodate different pipe sizes and configurations, making them suitable for various culvert applications.

- Q: Are plastic pipe fittings resistant to impact?

- Yes, plastic pipe fittings are generally resistant to impact due to their durability and flexibility. They are designed to withstand significant pressure and impact without cracking or breaking, making them a reliable choice for various plumbing and construction applications.

- Q: Can plastic pipe fittings be used for plumbing applications?

- Yes, plastic pipe fittings can be used for plumbing applications. Plastic fittings are commonly used for various plumbing systems, including water supply, drainage, and ventilation. They are lightweight, cost-effective, and resistant to corrosion, making them a popular choice in both residential and commercial plumbing installations. Plastic pipe fittings also offer flexibility in terms of size, shape, and connection options, providing versatility for different plumbing requirements.

- Q: Are plastic pipe fittings resistant to fire?

- Plastic pipe fittings have varying degrees of fire resistance, depending on the type of plastic used. PVC (polyvinyl chloride) fittings, for example, have low resistance to fire and can melt or burn when exposed to high temperatures. On the other hand, CPVC (chlorinated polyvinyl chloride) fittings are specifically designed to be more flame-resistant and can withstand higher temperatures without melting or burning. It is essential to choose the appropriate plastic pipe fitting based on the specific fire safety requirements of the installation.

- Q: Can plastic pipe fittings be used for landfill leachate collection?

- Yes, plastic pipe fittings can be used for landfill leachate collection. Plastic pipes and fittings are commonly used in landfill leachate collection systems due to their durability, resistance to corrosion, and cost-effectiveness. These fittings are designed to withstand the harsh conditions and chemicals present in leachate, making them a suitable choice for this application.

Send your message to us

Threaded Plastic Pipe Fittings - China PP-R Equal Tee Fittings for Industrial Applications

- Loading Port:

- Dalian

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords