Ceramic Fiber Textiles - High Quality Standard Small Zirconia Ceramic Tube for Optical Fiber Wire with Manufactured

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Type: | Ceramic Parts | Application: | Structure Ceramic | |

| Material: | Zirconia Ceramic, zirconia ceramic | Model Number: | AV-zirconia ceramic structure | Brand Name: | AV |

| delivery time: | 30-45working days | characteristic: | high hardness/Anticorrosion/high temperature resistance | Surface: | Good Polished |

| Used in: | Textile industrial | life time: | Long service life | MOQ:: | 1Pcs |

| Payment terms: | 100%TT in advance |

Packaging & Delivery

| Packaging Detail: | Standard export packing |

| Delivery Detail: | 30-45days after receiving your payment |

Specifications

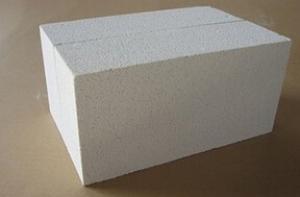

Manufacture of zirconia ceramic structure

Anticorrosion and eco-friendly

temperature resistance

Best price with good quality

Zirconia ceramic struction/Zirconia ceramic rod/aluminium ceramic struction

Zirconia grinding media is the most durable and efficient media for ball milling and attrition milling of ceramic material

Zirconia grinding media provides a virtually contamination-free ball milling solution for a variety of industries.

Advantages of Zirconia Grinding Media:

1)Ultra low wear loss as a result of the transformation-toughening mechanism unique to the yttrium stabilited zirconia(YST) material system

2)Higher grinding efficiency and reduced grinding time due to the higher density of zirconia (compared with alumina and glass)

3)Most durable grinding material, reducing operational cost in the long run. Wear rate substantially lower than Al2O3, CeO2-ZrO2, and MgO-ZrO2 grinding media.

4)Suitable for high velocity operations and wet grinding operations.

Technical Specifications:

Property | Unit | Parameter |

Content | wt% | 94.6% ZrO2 5.2%Y2O3 |

Packing density | kg/L | 3.5 (Dia5mm) |

Density | g/cm3 | 6.00 |

Hardness(HV) | GPa | >12 |

Elastic modulis | GPa | 200 |

Thermal conductivity | W/m.K | 3 |

thermal Expansion coefficient | 10×10-6/°C (20 to 400) | 9.6 |

Pressing intensity | KN | ≥25(Dia5mm) |

Fracture tenacity | MPam½ | 8 |

Grain size | µm | ≤0.5 |

Specification Available:

Ball:Dia0.8,Dia1.0,Dia1.2,Dia1.4,Dia1.6,Dia1.8,Dia2,Dia3,Dia5,Dia6.5,Dia7,Dia8.5,Dia10,Dia12,Dia15,Dia20,Dia25,Dia30,Dia35mm ect;

Cylinder:Dia5×5,Dia7×7,Dia10×10,Dia12.7×12.7,Dia15×15,Dia20×20mm, ect.

Applications:

1, For grinding wear-resistant, corrosion-resistant products: paints, textiles, paints, printing and dyeing

2, For grinding high strength, high toughness products: magnetic materials, piezoelectric ceramics, dielectric ceramics

3,To prevent pollution: medicine, food, cosmetics

4, Ceramics: Electronic ceramics, refractory ceramics, structural ceramics

- Q: Is aluminum silicate fiber completely insulated from heat transfer?

- Fire-resistant insulation layer is used to make ceramic fiber module insulation, thermal insulation thickness of four hundred mm, the ceramic fiber blanket double extrusion, ceramic fiber module in parallel sorting, the trolley furnace wall temperature to plate temperature rise of forty-five degrees, which is almost a best isolation effect.

- Q: What is the function of (ceramic) ceramic powder?

- Opaque porcelain: cover the color of the base crown and increase the retentionNeck edge porcelain: also called neck porcelain, darker color, showing neck colorBody porcelain: also called dentin porcelain, the main porcelain powder, used to obtain the natural beauty of dentinEnamel porcelain: also called cut end porcelain, used for cutting ends, translucencyTransparent porcelain: reflects the natural and transparent shape of teethGlaze powder: colorless and transparent, simulating the luster of enamelThere are modified porcelain, dyed porcelain, gums, porcelain and so on, can show different colors and special restoration needs.

- Q: Can ceramic fibers be spun?

- Ceramic fiber itself is relatively brittle, silk is relatively short, spinnability, but after adding viscose (differential polyester glass fiber, even pulp) as the heart can be spun,

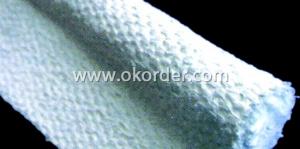

- Q: What are the uses of ceramic fiber blankets?

- The ceramic fiber blanket has a strong resistance to wind erosion, and can be directly contacted with flame and high-speed airflow. Because of its excellent fire resistance, high temperature stability, high thermal shock resistance, low heat capacity and high temperature conditions, high compressive strength.

- Q: What's the temperature of the high temperature ceramic fiber cloth and ceramic drill cloth?

- The ceramic fiber cloth is only one kind of one thousand degree temperature resistance. It is reinforced cloth for steel wire.

- Q: What are the differences between digital textile printing ink and printing ink?

- Under the new economic environment, the textile industry will enter a short process, digital production mode. Nowadays, more and more printing and dyeing mills use wide format inkjet printing to produce.

- Q: What are the man-made fibers polluting the environment?

- [] is a man-made fiber synthetic fiber as raw materials by using natural polymer cellulose or protein compounds in nature (such as wood, cotton, rice straw, bagasse fiber or milk, soybean, peanut protein, etc.) through a series of chemical and mechanical processing and made of cotton, wool and silk as similar to the textile fiber. Such as artificial cotton, rayon and so on.

- Q: The difference between ceramic fiber cloth and ceramic fiber paper

- Ceramic fiber paper and ceramic fiber cloth are refractory insulation materials, which can be used for insulation and heat preservation

- Q: Which is better, ceramic fiber or spray velvet?

- Different applications of two kinds of ceramic fiber cotton:In 1, production of HLGX ceramic fiber module: rejection due to thick and long silk fiber is better than spraying silk carpet, in the block made of the folding process, blowing fiber blankets easily broken and torn, and thrown silk fiber blanket can be folded very closely and not easy to damage, the quality will directly affect the block lining quality;The vertical layer 2, large boiler insulation blanket shop carpet fiber application: rejection due to long and thick, has better tensile resistance, more durable, so the rejection is better than spray carpet carpet;3, application of ceramic fiber textile, silk fiber thick and long and has good spinnability, the ceramic fiber thrown silk became the production of ceramic fiber textiles (cloth, tape, rope, pipe and other special materials);

- Q: Does the component of textiles contain 70% acrylic? Does it hurt the body?

- Acrylic may sound strange, because it is a new word that has appeared on the mainland in the last two years. It was not until 2002 that the advertising industry, furniture industry and handicraft industry were gradually understood by a few. "Acrylic" is a transliteration of foreign words, English is ACRYLIC, it is a chemical material. The chemical name is called "PMMA", which belongs to propylene alcohol, commonly known as "specially treated organic glass". In the application industry, its raw materials usually appear in the form of particles, plates, pipes and so on.

Send your message to us

Ceramic Fiber Textiles - High Quality Standard Small Zirconia Ceramic Tube for Optical Fiber Wire with Manufactured

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords