Ceramic Fiber Textiles Square Braided Packing

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ceramic fiber square braided packing is dense, resilient, high

performance ceramic fiber material fabricated from E-glass or

stainless steel wire 304 or 310 inserted ceramic fiber yarn which

braided around a core of ceramic fiber cord to form a packing in

square section.

Product Characteristics

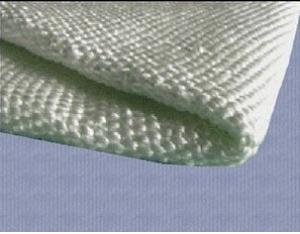

Ceramic fiber packing is made of high quality ceramic fiber woven.

Ceramic fiber Braided rope products are available in round and square form and produced by plaiting ceramic

fiber yarns around a central ceramic fiber core, resulting in a high strength, high density product with low

compressibility. Each yarn is reinforced with a single filament glass fiber or alloy wire depends on its work

temperature requirement. Those products are especially recommended for heavy duty applications.

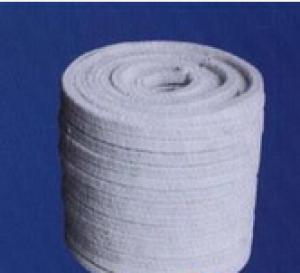

Our ceramic fiber rope products are specifically designed and developed with temperature use limits from

450°C to 1000°C for thermal protection in low, medium, and high-temperature ranges.

Product Application

Ceramic Fiber Packing is suitable for high temperature , high pressure machines, pumps , valves, sealing

equipment : metal processing , boiler doors, door temperature , high temperature , high pressure machines,

pumps, valves industry ; can be widely used in the chemical, power, paper , food, pharmaceutical media , etc. ;

cleansing fluid or paste , salt , lotions , oils, hydrocarbons, solvents , paper pulp .

Physical Property

Pressure | 2-40 | Rotary Pump | 2 | M Pa *10 bar |

Reciprocating Pump | 2 | |||

Valve | 10 | |||

Temperature | -40-1260 | °C | ||

Velocity | 2-8 | M/s | ||

Density | 0.7-0.9 | G/cm3 | ||

PH value | 4-11 | |||

- Q: Is aluminum silicate fiber completely insulated from heat transfer?

- Aluminum silicate fiber module in the well sealed at the same time, the thickness of heat insulation protection cases, can be isolated from the transfer of hot air to the maximum, complete isolation is not possible, the total fiber trolley furnace as an example, long-term use temperature of one thousand degrees, in addition to the door is sealed by the ceramic fiber packing do seal

- Q: What is the function of (ceramic) ceramic powder?

- Opaque porcelain: cover the color of the base crown and increase the retentionNeck edge porcelain: also called neck porcelain, darker color, showing neck colorBody porcelain: also called dentin porcelain, the main porcelain powder, used to obtain the natural beauty of dentinEnamel porcelain: also called cut end porcelain, used for cutting ends, translucencyTransparent porcelain: reflects the natural and transparent shape of teethGlaze powder: colorless and transparent, simulating the luster of enamelThere are modified porcelain, dyed porcelain, gums, porcelain and so on, can show different colors and special restoration needs.

- Q: Is everybody's ceramic fiber cloth poisonous?

- Ceramic fiber products with excellent heat resistance, with heat-resistant alloy reinforced aluminum silicate dimensional textiles, continuous use temperature of 1000 degrees, excellent acid resistance and oil, water vapor corrosion capacity.

- Q: Can ceramic fibers be spun?

- The utility model can also achieve higher strength by increasing metal wire reinforcement, and finally can be made into products such as yarn, cloth, belt, rope, packing, etc., and the utility model has wide application.

- Q: What are the uses of ceramic fiber blankets?

- Ceramic fiber blanket is mainly used for high temperature, tough, self bearing high strength of the place, but also used for high airflow speed, mechanical destruction of large places. Ceramic fiber blanket can be used in these occasions.

- Q: What's the temperature of the high temperature ceramic fiber cloth and ceramic drill cloth?

- High temperature ceramic fiber cloth is made of ceramic fiber cotton, E-glass filament, high temperature resistant stainless steel alloy wire with a special process, high strength, good flexibility, high machinability, not only has high temperature heat insulation performance, has the flexibility of common textiles.

- Q: What are the differences between digital textile printing ink and printing ink?

- 3. acid ink:Suitable for jet printing of silk, wool and nylon;4. coating ink:Suitable for direct printing of all textiles.

- Q: What are the man-made fibers polluting the environment?

- [] is a man-made fiber synthetic fiber as raw materials by using natural polymer cellulose or protein compounds in nature (such as wood, cotton, rice straw, bagasse fiber or milk, soybean, peanut protein, etc.) through a series of chemical and mechanical processing and made of cotton, wool and silk as similar to the textile fiber. Such as artificial cotton, rayon and so on.

- Q: Which is better, ceramic fiber or spray velvet?

- With the blowing of thrown silk cotton is two kinds of refractory ceramic fiber cotton cotton in the market at present, according to different production process is defined. Because of the different process, the characteristics of the two kinds of fire-resistant cotton are also different. According to different characteristics, they are applied in different heat insulation fields respectively. Ceramic fiber cotton, also known as aluminum silicate fiber cotton, its main purpose is to use other forms of refractory products, production and processing of raw materials.

- Q: Does the component of textiles contain 70% acrylic? Does it hurt the body?

- Acrylic has high transparency, light transmittance of 92%, a "plastic crystal" reputation. And excellent weather resistance, especially for outdoor, in other plastic crown, and has a good surface hardness and gloss, processing plasticity, can be made into a variety of shapes and products needed. There are a wide variety of boards, rich in color (including translucent swatches), and another feature is that the plate is still able to maintain high transparency.

Send your message to us

Ceramic Fiber Textiles Square Braided Packing

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords