Ceramic Fiber Board 1260 STD from CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CERAMIC FIBER BOARD ---STD

Classification Temperature (℃) | 1260 |

Working Temperature (℃ ) | 10 00 |

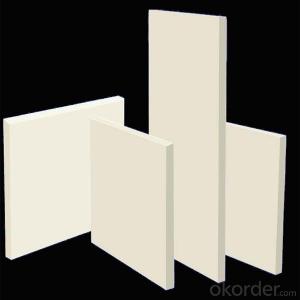

Color | White |

Bulk Density (kg/m3 ) | 240-300 |

Thermal Conductivity(W/m.k) | |

400℃ | 0.067 |

600 ℃ | 0.094 |

800 ℃ | 0.136 |

1000 ℃ | 0.152 |

1200 ℃ | 0.190 |

1300 ℃ | - |

Thermal Shrinkage 24hrs (%) | 1200℃ |

-3.3 | |

Chemical Composition (%) | |

Al2O3 | 45-47 |

Al2O3+ SiO2 | 97-98.5 |

Note: Technical Data are typical results from test pieces. This information, subject to change, is offered solely for your consideration. Users of our products should make their own tests to determine the suitability of each product for their particular purposes.

Classification Temperature:

YESO 1000 Board:1000°C

YESO 1260 Board:1260°C

YESO 1400 Board:1400°C

YESO 1500 Board:1500°C

YESO 1600 Board:1600°C

YESO 1700 Board:1700°C

YESO 1800 Board:1800°C

Characteristics:

Asbestos free

Smooth surface, identical bulk density and thickness

Excellent high temperature strength and thermal stability

Low thermal conductivity

Low shrinkage

Low thermal capacity

Resistance to gas flow velocity

Direct contact with the flame

Easy cut and installation.

Typical Applications:

Back-up lining of high temperature furnaces.

Lining and fire board for Ceramic tunnel kiln , roller kiln , shuttle kiln and other thermal equipment

Back-up and hot-face insulation material for furnaces or aluminum industry

Insulation material for Metallurgy, machinery , chemical, optical, and environmental protection industries

Other Industry insulation material

Standard Size and Package:

Standard size:1000x600mm

1200x1000mm

Thickness:6,8,10,15,20,25,30,40,50,60,70,80,90,100,120mm

Standard Density:280,300,350,400kg/m³

OEM according to customers’ inquires.

Package: Carton+pallet

Introduction:

CNBM (China National Building Material) Group is the largest comprehesnsive building materials group in China that in intergrate scientific research,manufacturing and logistics into one entity.the largest building materials and equipment specialists in China. Upon State Council approval, today CNBM owned more than 300 subordinate manufacturing factories and servicing companies. There are 6 fully owned public listed companies and 11 partially owned with substantial shares public listed companies. In many of these fields,CNBM is playing the leading role in the building industry in the country.

- Q: What are the standards for ceramic fiber boards?

- Ceramic fiber board currently only GB, and many production enterprises are also in accordance with GB to perform.

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Ceramic fiber surface roughness, accurate size, good toughness, can be arbitrarily cut, good insulation effect; ceramic fiber board can be distinguished according to the temperature, heat is widely used in the back lining of industrial furnace and kiln temperature, kiln is an important guarantee for energy saving, high yield and quality factors of A.

- Q: Refractory insulation board, pressure plate, nano heat transfer plate, calcium silicate board and ceramic fiber board, which is good?

- Sheng Yang series of ceramic fiber board is based on the traditional process of comprehensive upgrading of the excellent vacuum forming insulation materials, slag ball content of less than 3%, fiber distribution uniformity, internal and external strength consistent, size controllable.Ceramic fiber board is made by spraying superfine ceramic fiber through water washing, slag removal, fiber freezing and vacuum forming. The product has superior high temperature resistance, excellent rigidity and toughness.

- Q: What are the sound-absorbing fiber boards?

- Ordinary materials have sound-absorbing effect, just how much difference. And when it comes to sound-absorbing board, we are only sound-absorbing coefficient of more than 0.3 of the material known as sound-absorbing material.

- Q: What is the difference between ceramic fiber board and nano ceramic fiber board?

- The nano ceramic fiber board through the introduction of nanotechnology, the special production process, product performance has been greatly improved, high strength, low thermal conductivity, good heat insulation performance, energy saving effect is obvious, which improves the safety of the furnace, and in high temperature and high pressure conditions, can also play a good performance the product.

- Q: What are the specifications of the ceramic fiber board?

- Ceramic fiber board common specifications are: 600*400, 900*600, 1000*600 and 1000*1200mm, thickness 10/20/25/30/40/50mm, thinnest can do 6mm.Depending on the temperature range, it can be divided into:Common ceramic fiber board HLGX-164Standard ceramic fiber board HLGX-264High purity ceramic fiber board HLGX-364High alumina ceramic fiber board HLGX-464Ceramic fiber board containing zirconium HLGX-564

- Q: What are the differences between nano ceramic plate and ceramic fiber board?

- Ceramic fiber board is a kind of ceramic fiber cotton produced by injection technology. It is made by continuous production and advanced technological production line.

- Q: What are the uses of ceramic fiber boards?

- According to the conditions of use, can be divided into:Fire dragon high purity ceramic fiber fire block HLGX-364DThe dragon high alumina ceramic fiber fireproof plate HLGX-464D

- Q: Is there any difference between ceramic silicon fiber board and ceramic fiber board?

- Ceramic fiber board is aluminum silicate fiber board, a refractory material. Even after heating, good mechanical strength is maintained. The product is a fibrous insulation product that is rigid and has a supporting strength compared to fiber blankets. Features: ceramic fiber board has excellent quality, toughness and strength, besides, it has excellent resistance to wind erosion. The utility model has the advantages of no heat expansion, light weight, convenient construction, and arbitrary shearing and bending. The utility model is an ideal energy-saving material for kilns, pipes and other heat preservation equipment.

- Q: How much pressure can the ceramic fiber board withstand?

- Ceramic fiber board has the characteristics of tough, high compressive strength, excellent resistance to high temperature and excellent supporting force. The compressive strength of ceramic fiber board increases with the increase of density of ceramic fiber board.

Send your message to us

Ceramic Fiber Board 1260 STD from CNBM

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords