Carbon steel russian standard flanged gate valve Z41H-26C

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

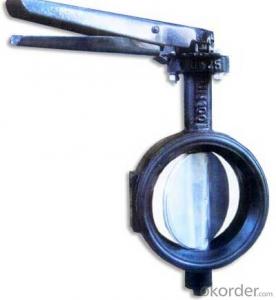

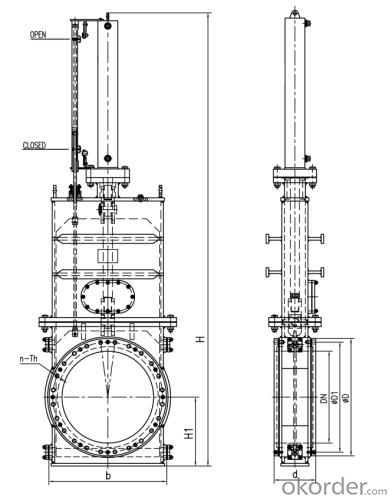

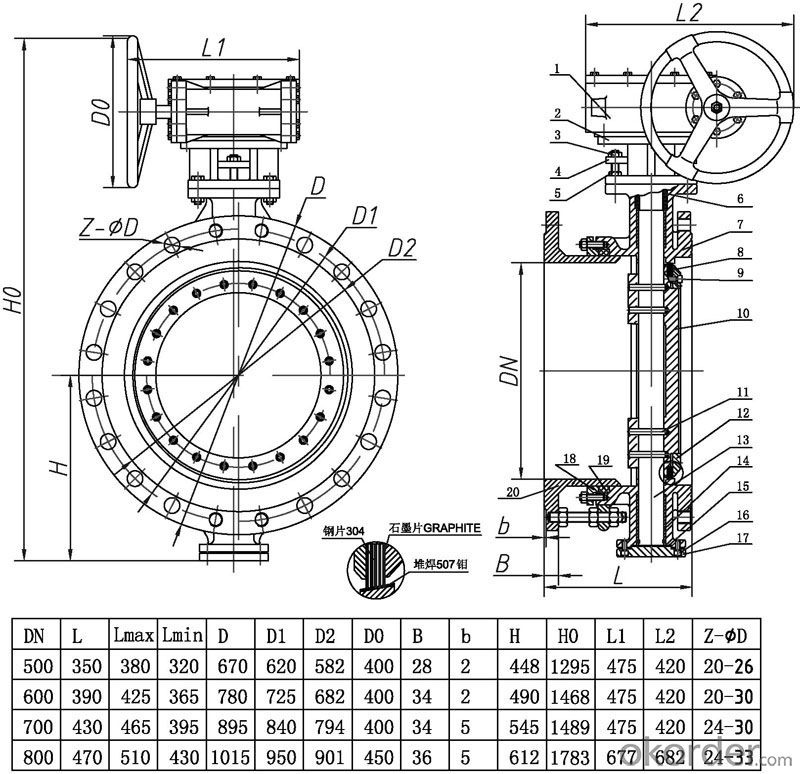

3. Images

4. Gate valve Specification

5.FAQ

1. What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2. What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q: How to identify the good or bad of the valve, without pressure test and instrument?

- You can see what the material inside the valve ~ basically copper heart relatively durable, solid ~!

- Q: How to suppress the valve?

- Valve pressure is generally divided into 2 parts. One is shell pressure test, one is sealing test pressureShell pressure test is 1.5 times the pressure of the valve. For example, the pressure on your valve is 16 pressure. Then the shell test pressure will reach 24 pressureThe pressure on the seal is 1.1 times the pressure of the valve. For example, the pressure on your valve is 16 pressure. Then the pressure test on the seal will reach 17.6 pressure. That's all right.

- Q: What do you mean by "P54" in the valve z962y-p54 100V?

- 1, P54 is the valve body temperature is greater than or equal to 545 degrees, 100V is 10Mpa, that is, 100 kilograms, the valve name on all.2, valve (Famen) is a fluid conveying system control components, with cut-off, regulation, diversion, and prevent reverse flow, voltage regulation, shunt or overflow, pressure relief and other functions. Valves used in fluid control systems, from the simplest stop valve to a very complex automatic control system used in a variety of valves, a wide range of varieties and specifications. Valves can be used to control air, water, steam, a variety of corrosive media, mud, oil, liquid metal and radioactive media and other types of fluid flow. The valve according to the material is divided into cast iron valves, cast steel valves, stainless steel valves (201, 304, 316), chrome molybdenum steel, chromium molybdenum vanadium steel valves, valve, dual phase steel valves, plastic valves, non-standard customized valve material etc..

- Q: The expert can tell me how to install this valve, and what fittings to use on both sides

- It looks a bit like the butt weld butterfly valve. The two sides are welded to the pipe. There is a step on either side of the valve. Overhead welding

- Q: What are the valve types H, F, and Y? What are the meanings of these 3 letters?

- Please refer to "JB/T308-2004 valve model preparation method"Sealing surface material codeH Cr13 stainless steelF fluoroplasticY cemented carbide

- Q: What valve is the YQZ45X-16Q?

- Specifically, YQ usually is the enterprise code, Z valve, 4 representative flange, 5 representatives of the dark bar, X (soft) rubber seal (gate coated with rubber material), nominal pressure 16 representative (PN) 1.6Mpa, Q on behalf of the valve body is made of ductile cast iron. If you add the valve bore (DN), it will be more detailed.

- Q: 1. What does valve 13Cr&FHF mean? 2, valve WC6 (F11) what does that mean? 3. What does valve P280GH mean? 4. What does valve A335P22 mean?Thank you

- 1. What does valve 13Cr&FHF mean? 2, valve WC6 (F1113Cr&FHF WC6 body material

- Q: There is a rectangular hole in the valve core, which the heating company repairman gives to the bolt. Rest assured, I do not want to heating, but my indoor temperature is low, I suspect that the repairman mischief, deliberately give me lower temperature

- The valve has a device like a cylinder lock that opens with a special key.The heating valve refers only to a radiator system accessories, is a type of valve, the valve commonly used heating system on the market is mainly divided into: gate valve, ball valve, safety valve, balance valve, globe valve, regulator valve, relief valve, pneumatic control valve.

- Q: How do you calculate the flow of the valve?

- Valve flow calculation value is very vague, pipe pressure, back pressure, medium viscosity, medium temperature, valve structure, and so on, will affect the calculated value.

- Q: Why can't the clip type check valve be directly connected with the pipe mouth or other valves?

- The clip type check valve is made up of two discs to prevent backflow.If the clip check valve is connected to the other valve, the disc may touch the valve and cause the check valve not to be fully opened or closed. This is a preliminary analysis of "enter the valve", for reference only!

Send your message to us

Carbon steel russian standard flanged gate valve Z41H-26C

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords