carbon steel pipe ,carbon steel pipe price per ton,carbon steel seamless pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of carbon steel pipe:

Brand | seamless steel pipe |

Material | St35,St45,St52,E215,E235,E355,10,20, A106,A179,A192,A210,T11 |

T22,T12, AISI4130,SAE1010,SAE1020.etc | |

Standard | Meet or exceed ASTM,ASME,API,ANSI and DIN standards. |

ASTM A106/A179/A192/A210/A213/A519 etc. | |

DIN2391/DIN17175/EN10305 etc | |

GB8162/GB8163/GB3639 etc | |

Technique | Cold Drawn/Cold rolled |

Usage | 1. auto and motorcycle steel pipe |

2. Gas spring steel Tube | |

3. Boiler Pipe | |

4. Low and middle pressure fluid transportation pipeline | |

5. Hydraulic system steel tube | |

6. Electric industry |

Application | Cold drawn or cold rolled precision seamless steel tubes for hydraulic pressure and pneumatic services. |

For Auto use,machinery use,oil cylinder tube,motorcycle shock reducer use,auto shock reducer inner cylinder,gas spring use etc. | |

Seamless steel pipes for low and medium pressure boiler, high pressure boiler, ship-building,Liquid service, petroleum cracking, chemical fertilizer equipment,Drawing-oil-equipment and structure purposes. |

2、Main Features of the Seamless Pipe ASTM A106/53 ( carbon steel pipe):

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Seamless Pipe ASTM A106/53 ( carbon steel pipe) Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

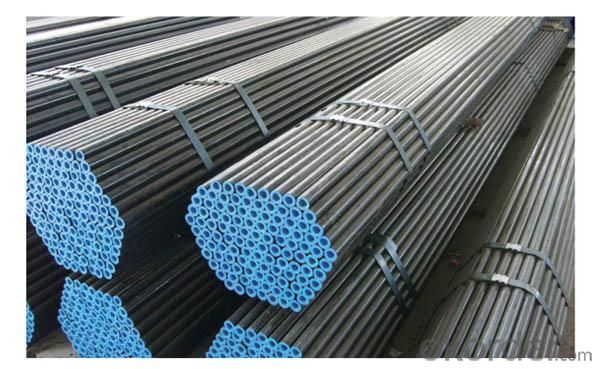

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Pipe ASTM A106/53 ( carbon steel pipe):

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

6、Seamless Pipe ASTM A106/53( carbon steel pipe) Images:

- Q: What are the common applications of steel pipes in the water distribution system?

- Steel pipes are commonly used in water distribution systems for various applications such as transporting water from treatment plants to homes, buildings, and industries, as well as for underground water mains and fire hydrant systems.

- Q: Can steel pipes be used for cooling systems?

- Steel pipes are a viable option for cooling systems. They are frequently employed in different scenarios, such as cooling systems, because of their robustness, strength, and ability to withstand high temperatures and pressure. Industrial cooling systems, in particular, benefit from steel pipes due to the harsh environmental conditions and corrosive fluids they often encounter. Moreover, steel pipes possess outstanding heat conductivity, which facilitates efficient heat transfer, rendering them a dependable choice for cooling purposes. Furthermore, steel pipes can be easily tailored, joined, and adjusted to fulfill specific cooling system needs. Nevertheless, it is crucial to ensure that the steel pipes utilized are adequately coated or insulated to prevent corrosion and minimize heat dissipation.

- Q: Can steel pipes be used for oil refinery applications?

- Yes, steel pipes can be used for oil refinery applications. Steel pipes offer many advantages for oil refinery applications including high strength, durability, and resistance to corrosion. They are able to withstand high pressure and temperature conditions that are common in oil refinery operations. Steel pipes are also easy to transport and install, making them a popular choice for oil refinery projects. Additionally, steel pipes can be customized to meet specific requirements such as size, thickness, and coating, making them suitable for a wide range of oil refinery applications.

- Q: Can steel pipes be used for transporting slurry?

- Yes, steel pipes can be used for transporting slurry. Steel pipes are known for their durability and strength, making them suitable for handling abrasive materials like slurry. The smooth interior surface of steel pipes helps to minimize friction and prevent clogging, ensuring efficient transportation of slurry. Additionally, steel pipes can withstand high pressure and are resistant to corrosion, making them a reliable choice for slurry transport.

- Q: How do you prevent corrosion in steel pipes?

- One effective way to prevent corrosion in steel pipes is by applying a protective coating, such as paint or epoxy, to the surface of the pipes. This barrier creates a physical barrier between the pipe and the surrounding environment, preventing moisture and corrosive agents from coming into direct contact with the steel. Additionally, regular inspection and maintenance of the pipes, including cleaning and repairing any damaged coating, can help identify and address potential issues before they lead to corrosion.

- Q: What is the outer diameter and wall thickness of DN40 steel pipe?

- DN40 pipe diameter 48.3mm diameter, allowable deviation of plus or minus 0.5mm it depends on what you have, the outside diameter of 45, there are other dimensions, you can see the manual

- Q: What is the role of steel pipes in the transportation of petroleum products?

- Steel pipes play a crucial role in the transportation of petroleum products as they provide a safe and efficient means of transferring oil and gas over long distances. These pipes are strong, durable, and resistant to corrosion, ensuring the integrity of the pipelines and preventing leakage or contamination of the products. Additionally, steel pipes have high heat resistance, making them suitable for transporting hot petroleum products. Overall, steel pipes serve as the backbone of the petroleum transportation infrastructure, facilitating the smooth and reliable delivery of these essential energy resources.

- Q: How are steel pipes used in the renewable energy industry?

- Steel pipes are widely used in the renewable energy industry for various purposes. They are commonly used in the construction of wind turbine towers, where they provide structural support and stability. Steel pipes are also used in the installation of solar panel systems, serving as a reliable conduit for transporting fluids, such as water or heat transfer fluids, within the system. Additionally, steel pipes are utilized in the transportation of renewable energy resources, such as natural gas or hydrogen, as they offer durability and strength to withstand high-pressure conditions.

- Q: What are the different pressure ratings for steel pipes?

- The different pressure ratings for steel pipes can vary depending on factors such as pipe size, wall thickness, and the type of steel used. Common pressure ratings for steel pipes range from 150 psi (pounds per square inch) to 2500 psi or higher.

- Q: What is the difference between steel pipes and fiberglass-reinforced pipes?

- The main difference between steel pipes and fiberglass-reinforced pipes lies in their composition and structural properties. Steel pipes are made primarily of iron and carbon, which provide high strength and durability. On the other hand, fiberglass-reinforced pipes consist of a composite material that combines a resin matrix with glass fibers, offering excellent corrosion resistance and high tensile strength. Additionally, steel pipes are heavier and require more maintenance, while fiberglass-reinforced pipes are lighter, easier to install, and have a longer lifespan.

Send your message to us

carbon steel pipe ,carbon steel pipe price per ton,carbon steel seamless pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords