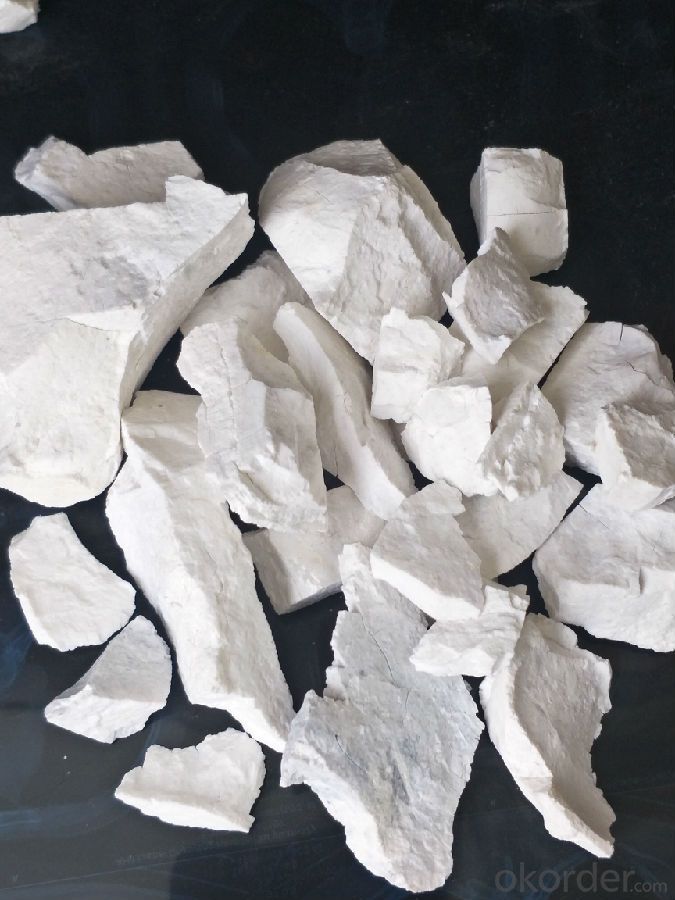

Calcined Kaolin Clay Powders for Refractory Fire Clay Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Place of Origin:China

Model Number:Calcined Kaolin

Type:Powder

Technique:Calcined Kaolin

Dimensions:300-5000 mesh

SiO2 Content (%):52±2%

Fe2O3 Content (%):≤0.5%

Al2O3 Content (%):45±2%

Moisture Content (%):≤0.5%

TiO2 Content (%):≤1.5%

K2O Content (%):<0.3%

Application:Refractory

Other Names:Calcined Kaolin

Product name: Kaolin

Payments terms:

1. 100% L/C at sight

2. 30% T/T prepayment, balance against BL copy

Delivery Time: Within 30 days after receiving L/C or 30% T/T prepayment

Advantage: Timely Shipment, High quality, Good performance

Packing: 1mt/bag or as customers' requirements

Size: powder

Sample supply: free sample

Color: white

MOQ: 25Mt

Supply Ability

Supply Ability:300 Metric Ton/Metric Tons per Month

Packaging & Delivery

Packaging Details1MT/bag or as customers' requirements.

- Q: How to use fire-resistant soil?

- Clay refractory soil 1, characteristics and uses: Clay refractory brick is a weak acid refractory material, its thermal stability is good, suitable for hot air furnace, all kinds of boiler lining, and flue, smoke room, etc.. 2, product specifications form: standard shape, general, special-shaped and special-shaped brick. Physical and chemical properties of fireclay bricks.

- Q: What does fire-resistant insulation coating have?

- Refractory thermal insulation material mainly refers to the inorganic thermal insulation material and composite thermal insulation material. According to the shape, it can be divided into: Finishing of fibrous shape, mineral?cotton, rock wool, glass wool, aluminum?silicate?wool, ceramic fiber, etc. Diatomaceous earth of microporous pile, calcium silicate, expanded perlite,expanded vermiculite,aerated concrete, etc. Foam glass of bubble shape, volcanic ash glass, foamed clay, foamed?concrete, gelatine powder polyphenyl granule heat insulating slurry of pasty form, etc. Their common feature is fire-retardant and firproof. It can be used in buildings with high requirements of fire?rating. Calcium silicate, aluminum silicate and asbestos can also be used for piping insulation of heat transport with high temperature. Hope it is helpful to you.

- Q: Who knows what is the requirement for fireproofing of interior decoration materials ?

- In addition to the underground building, combustion performance level of interior decoration materials inside windowless room , in addition to a class, should advance 1 level based on the original provisions . Library, archives and rooms storing artifacts, ceilings, walls should use class A decoration materials, and the ground should use decoration materials no lower than class B. When high temperature parts of lighting and lighting lamps and lanterns are close to non - grade A decoration materials should be taken, fire prevention measures such as thermal insulation and heat dissipation must be taken. Combustion performance level of materials used for lighting should be no lower than B. Kitchen ceiling, wall and floor should used class a decoration materials.

- Q: About the market issues of thermal insulation material and refractory material.

- In fact, the thermal insulation material produced by the Sichuan-Benniao Hing construction company is very good, you can get the company's information just by inputing the Sichuan-Benniao Hing construction company into Baidu

- Q: What's the difference between refractory metal raceway and fireproof raceway?

- Hello, I'm very glad to answer your question. As far as I know, anti-fire groove box is made by the polymerization reaction of high polymer material and halogen-free flame retardant polymeric material. It possesses excellent mechanical properties and environmental protection property, nice appearance, and diversified colors. As a kind of fully enclosed cable bridge, it is applicable for communication signals, and laying of computer cables and control cables of highly sensitive systems. When used in heavy corrosive environment and outdoor dust environment, it has good protective effect on cables. It boasts many advantages of fire retardance (fire resistance rating is above B grade), corrosion resistance, anti-aging, high strength, light weight, and easy installation. Hope my answer is helpful for you. Hope my answer can be accepted.

- Q: What kind of refractory bricks material is best?

- It depends on your purposes. In general, aluminous fireclay brick is usually used. GB/T 3994-2005 insulating fireclay brick. Bricks with good material are as follows: high-grade thermal insulation refractory brick, GB/T 3995-2006 high alumina thermal insulation refractory brick. Model is A13, and the texture is aluminium oxide. A13 50u, high grade heat insulating brick B5; intermediate heat insulating brick B2, etc.

- Q: which kind of refractory is commonly used in the industry

- Therefore it is known as special fire-resistant materials, such as yttria, high alumina raw material (sometimes neutral), olivine,which is used for alkalinity furnace, dolomite, and we roughly divided into several categories, beryllia, cerium oxide, these materials have a strong alkaline slag resistance, thorium oxide, lime, serpentine, which is picked from these refractory raw materials. the raw materials of basic refractory materials are mainly magnesia clay and titanium oxide, but because not many sources of raw materials, it can not be widely applied in the refractory industry, and we can analyze which kind of materal is processed by the pulverizer. There are many kinds of refractory materials, rotary?kiln can only be used in particular circumstances. These materials have a variety of slag resistance at different degrees. the main material of special refractories is zirconium oxide. the refractory clay is the most basic and most widely used raw material in the refractory industry.

- Q: what are the types of piping insulation material fire?rating?

- according to China's national standard GB8624-97, the combustion performance of construction materials can be divided into several grades grade A: Incombustible building material: Almost no burning material. Class B1: nonflammable building material: nonflammable material has a good flame resistance effect. when it meet the open fire in the air or burnd at high temperature, it is difficult to spread quickly, and when the fire source is removed, the combustion stop immediately. Class B2: flammable building material: flammable material has a good flame resistance effect. when it meets open fire in the air or at high temperature, it will immediately burst into flames and easily cause fire spread, such as wooden column, timber roof truss, timber beam, and wooden stairs,ect.. Class B3: inflammable building material: No flame resisting effects, highly flammable, high fire risk. 2, external wall thermal insulation materials, in accordance with fire rating, can be divided into1) grade A combustion performance thermal insulation material: Rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite ect.. 2) class B1 combustion performance insulation materials: Extruded polystyrene board (XPS) after special treatment / Special treatment of polyurethane (PU), phenolic aldehyde, gelatine powder polyphenyl granule, etc. 3) combustion performance of class B2 insulation material: molding polystyrene board(EPS), extruded polystyrene board (XPS), polyurethane (PU), polyethylene (PE), etc.

- Q: What's meaning of CN of fire-resistant material?

- The commonly used preparation methodsinclude shock compression, high-pressure pyrolysis, ion implantation, reactive sputtering, plasma chemical vapor deposition, electrochemicaldeposition, ion beam sputtering, , low-energy ion radiation, pulsed arc discharge,pulsed laser inducing, etc. But the compounding result of superhard materialis not ideal due to deposition of amorphous CN film, nanometer level sizedC3N4 crystalline grain set in the amorphous film and few large graincrystal.

- Q: Who knows about the types of Dalian thermal insulating and refractory materials?

- (1) rock wool board: the heat conductivity coefficient is 0.041-0.045. It is fire retardant, has a great temperature absorption while a poor thermal insulation performance. (2) glass wool: it is simple in construction and free in cutting. It has advantages of antibiosis, mould proof, aging resistance and anticorrosion, and can ensure a healthy environment. It has a low hygroscopicity and a stable physical property. (3) expanding polystyrene board(EPS board): thermal conductivity: 0.037-0.041, it has a good thermal insulation performance, cheap price but a poor intensity. (4) extruded polystyrene board(XPS board): thermal conductivity: 0.028-0.03, it has a better thermal insulation performance, high intensity, moisture resistance while it is expensive, and requires surface treatments during construction. (5) gelatine powder polyphenyl granule heat insulating slurry: heat conductivity coefficient: 0.057-0.06, it has a good flame resistance while a poor thermal insulation performance, as well as has high construction requirements and can be recycled. (6) polyurethane foam: heat conductivity coefficient: 0.025-0.028, it has advantages of waterproofness, thermal insulation, high intensity, high integrity, and good integrity, but it has a poor fireproof?performance and is more expensive. (7) rigid polyurethane: heat conductivity coefficient: 0.018-0.023, it has advantages of low heat conductivity coefficient and good thermal performance. When the unit weight of rigid polyurethane is 35 to 40kg per cubic meters, it is equivalent to half of the EPS. It is the one with the lowest heat conductivity coefficient among all the thermal insulation materials. (8) perlite slurry: heat conductivity coefficient: 0.07-0.09, it has advantages of fire and high-temperature resistance, and high water absorption but is poor in thermal insulation.

Send your message to us

Calcined Kaolin Clay Powders for Refractory Fire Clay Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 300 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords