Building Hoist Single Cage Construction Lifting

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Building Hoist Description

Feature: Building Hoist Condition: New Application: Construction

Payload(kg):2500 Lifting Speed(m/min):0~60 Motor Power(kw): 2*18.5

Safety Device: SAJ50-1.4 Cage: Single Counterweight: Yes

Certification: CE,ISO Place of Origin: China(Mainland) Model Number: Type:SCD250

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package Delivery Detail: 25-30days

Main Parts of Building Hoist

● Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

● Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process,

and ensures automated leveling.

● Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

● foundation type: with or without slop. If the foundation is lower than earth surface, there will not be slop. If the foundation is same as the earth surface, there will be slop.

● The steadiness during running mitigates concussion to mechanical parts, reduces wears of rack, pinion and the brake

and prolongs the spare parts'life.

● Cable drum and cable trolley are available, For height lower than 100m, usually we use cable drum and for height higher than 100m, cable trolley is used.

● Limiter: anti-roof collapse limiter-it is on the top of the mast sections which has no rack. Overload limiter, upper and lower travel limiter.

Building Hoist Images

CMAX Building Hoist

Mast Section

Driving Unit

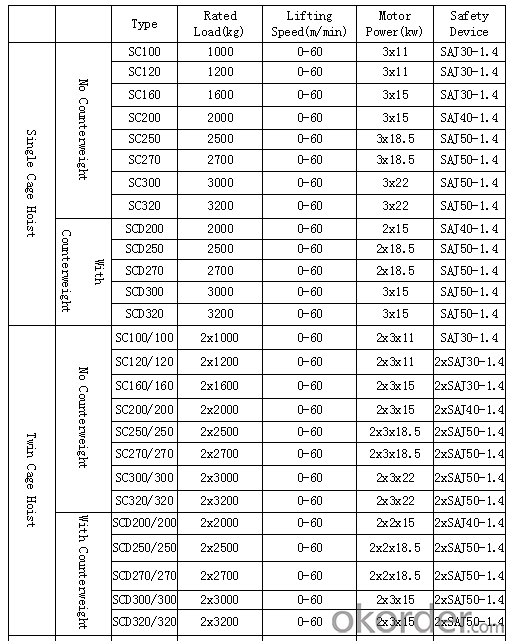

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

- Q: Is it possible to use a building hoist for lifting delicate or fragile items?

- <p>A building hoist is typically designed for heavy construction materials and not recommended for lifting fragile objects. The vibrations and force exerted during lifting can damage delicate items. For fragile objects, specialized hoists or cranes with controlled movements and gentle handling capabilities are advised to ensure safety and prevent damage.</p>

- Q: Explain the distinctions between electric and manual building hoists, focusing on their operation, efficiency, and use cases.

- <p>Electric building hoists are powered by electricity and offer faster operation, greater efficiency, and the ability to lift heavier loads. They are ideal for large-scale construction projects where rapid movement of materials is necessary. In contrast, manual hoists are operated by hand and are typically smaller, more portable, and require human effort to lift materials. They are suitable for smaller projects or where power supply is limited. Electric hoists are more automated and can be controlled remotely, while manual hoists require constant physical effort and are less efficient in terms of speed and load capacity.</p>

- Q: The question asks about the typical duration a building hoist can function before needing replacement or significant repair.

- <p>The lifespan of a building hoist can vary significantly based on factors such as usage frequency, maintenance, and the quality of the hoist itself. Generally, with proper care and regular maintenance, a building hoist can last anywhere from 10 to 20 years. However, heavy usage and inadequate maintenance can shorten this lifespan, while some high-quality hoists may exceed the average lifespan with fewer issues.</p>

- Q: What is the highest weight a building hoist can safely lift?

- <p>The maximum load capacity of a building hoist can vary significantly depending on the specific model and design. Generally, capacities range from 500 kg to 3,000 kg or more. It's crucial to refer to the manufacturer's specifications for the exact load capacity of any given hoist. Overloading a hoist can lead to accidents and damage, so it's essential to operate within the specified limits.</p>

- Q: This question asks for a comparison between two types of building hoists: those that are electric and those that use electric motors. It seeks to understand the key distinctions between these two systems.

- <p>Electric building hoists are powered directly by electricity and typically use simpler electric motors for lifting and lowering loads. They are generally easier to install and operate, with direct control over the motor speed and direction. On the other hand, electric-motor building hoists are more complex, often incorporating advanced motor technologies and control systems. These hoists may offer features like variable speed control, energy efficiency, and smoother operation. The main differences lie in the sophistication of the motor and control systems, with electric-motor hoists often providing more precise control and better performance for heavy-duty applications.</p>

- Q: Is it possible to use a building hoist for lifting heavy materials that cannot be manually lifted?

- <p>Yes, a building hoist is specifically designed for lifting heavy materials that are too heavy or cumbersome to lift manually. These hoists are engineered to handle significant weight loads and are commonly used in construction settings to move materials such as bricks, cement, and steel beams to various levels of a building. They are an essential tool for safe and efficient material handling in construction projects.</p>

- Q: This question asks about the measures taken to ensure that lifting equipment remains safe and functional in various weather conditions.

- <p>To ensure that lifting equipment is safe and reliable in all weather conditions, regular maintenance and inspection are crucial. Equipment should be designed with weather-resistant materials and should be tested periodically to withstand extreme temperatures, humidity, and precipitation. Protective covers or enclosures can be used to shield equipment from the elements. Additionally, training operators on the safe use of equipment in different weather conditions is essential. Emergency procedures should be in place for extreme weather events, and equipment should be regularly checked for wear and tear that could be exacerbated by weather conditions.</p>

- Q: What are the steps and considerations for maintaining a building hoist to ensure its safety and functionality?

- <p>To maintain a building hoist properly, follow these steps: Regularly inspect the hoist for any visible damage or wear. Lubricate moving parts as per manufacturer's recommendations. Ensure all safety devices are functioning correctly, including limit switches and emergency stop buttons. Check the hoist's electrical system for any signs of damage or wear. Keep the hoist clean and free from debris. Conduct a thorough inspection after any incident or near miss. Regularly test the hoist's load capacity to ensure it is within safe limits. Train operators on safe hoist operation and maintenance procedures. Always follow the manufacturer's guidelines and local regulations for maintenance and inspection.</p>

- Q: This question asks for the procedure or steps to operate a building hoist, which is a machine used to lift materials in construction.

- <p>To use a building hoist, first ensure it's properly installed and inspected. Familiarize yourself with its controls and safety features. Load materials evenly onto the platform, ensuring not to exceed weight limits. Activate the hoist by pressing the 'up' button to lift the materials. Maintain a safe distance while the hoist is in motion. Once at the desired floor, press the 'stop' button, then unload the materials. Always follow the manufacturer's guidelines and safety protocols to prevent accidents.</p>

- Q: Is it possible to utilize a single-rope lifting system in the context of a building hoist?

- <p>Yes, a single-rope lifting system can be used in a building hoist. This system is common in construction elevators, where a single rope is used to lift and lower the hoist's cage. The rope is attached to a motor at the top and passes over sheaves or pulleys to provide mechanical advantage. It is essential to ensure that the rope is strong enough to support the load and that the system is equipped with safety features such as overload protection and emergency braking mechanisms to prevent accidents.</p>

Send your message to us

Building Hoist Single Cage Construction Lifting

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords