Building Hoist SC300 3-phase spare parts

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Building Hoist Description

Condition: New

Application: Construction

Payload(kg):3000

Lifting Speed(m/min):0~60

Motor Power(kw): 3*22

Safety Device: SAJ50-1.4

Cage: Single

Counterweight: No

Certification: CE,ISO

Place of Origin: China(Mainland)

Model Number: Type:SC300

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package

Delivery Detail: 25-30days

Features of Building Hoist

●Due to the strict raw material procurement control system, our drive motors for construction hoist/ building lift /material elevator for bridge/ tower / chimney / building is guaranteed with safe and reliable performance.

●The steel, electrical components, hoist cables, high strength bolts and spare parts are all introduced from well-known international and domestic suppliers.

●Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

● Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process,

and ensures automated leveling.

● Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

● The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

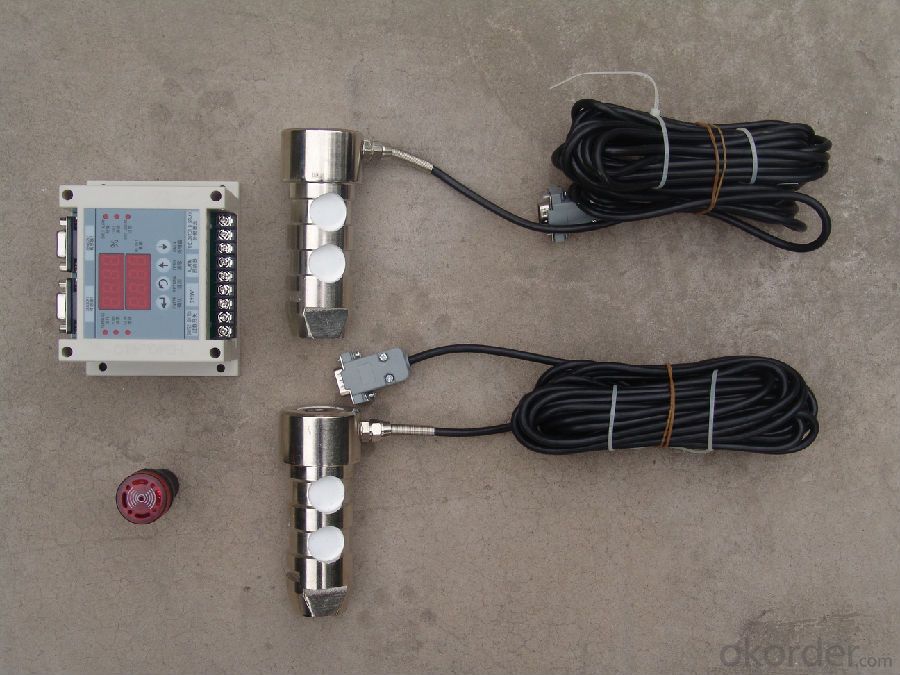

Building Hoist Images

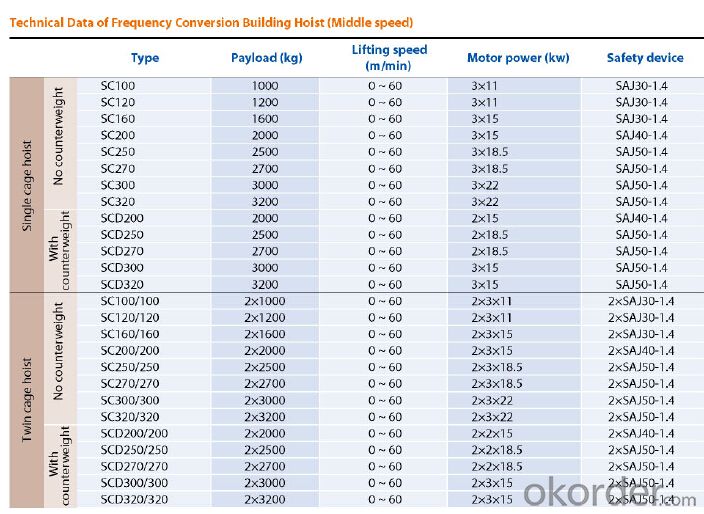

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

- Q: This question asks whether building hoists can be used in both indoor and outdoor environments.

- <p>Building hoists can be used both indoors and outdoors, but their usage depends on the specific type and design of the hoist. Material hoists, for instance, are often used outdoors in construction sites to lift materials vertically. On the other hand, dumbwaiters are hoists designed for indoor use, typically to transport goods between floors in buildings. It's important to ensure that the hoist is suitable for the environment in which it will be used, considering factors such as weather conditions, building structure, and safety regulations.</p>

- Q: Is it possible to utilize building hoists in environments with high altitudes?

- <p>Yes, building hoists can be used in high-altitude environments, but their performance may be affected. At high altitudes, reduced air density can lead to decreased efficiency in hoist operations, particularly those powered by combustion engines. It's crucial to select hoists designed for high-altitude use, which may include features such as high-altitude ignition systems and special lubricants. Additionally, regular maintenance and adjustments to the hoist's operation parameters are necessary to ensure safety and optimal performance.</p>

- Q: Explain the distinctions between electric and hydraulic power sources used in building hoists.

- <p>Electric hoists use electric motors to generate power, which is more environmentally friendly and requires less maintenance. They are often quieter, easier to control, and can be more energy-efficient. Hydraulic hoists, on the other hand, rely on fluid pressure to generate power. They can provide greater lifting capacity and are often used in heavy-duty applications. Hydraulic systems can be more complex to maintain and repair, and they may not be as energy-efficient as electric hoists. However, they offer smooth and controlled lifting, which is beneficial in certain construction scenarios.</p>

- Q: This question asks for the method to determine the maximum weight that a building hoist can safely lift.

- <p>To calculate the lifting capacity of a building hoist, you need to consider several factors. First, identify the hoist's rated capacity, which is usually specified by the manufacturer. This is the maximum weight the hoist is designed to lift. Next, assess the condition of the hoist, including any wear and tear that might affect its performance. Check the hoist's mechanical components, such as cables, pulleys, and motors, to ensure they are in good working order. Additionally, consider the weight of the load you intend to lift and any additional factors like the frequency of lifts or the height of the lift. Always operate within the hoist's rated capacity and follow safety guidelines to prevent accidents.</p>

- Q: Is it possible to use a lifting device to assist in lifting a person who is too heavy to lift manually?

- <p>Yes, lifting devices such as hoists or mechanical lifts can be used to safely lift someone who is too heavy to lift manually. These devices are designed to support the weight and reduce the risk of injury to both the person being lifted and the caregiver. It's important to use the appropriate equipment for the individual's weight and to follow safety guidelines and manufacturer's instructions to ensure proper and secure lifting.</p>

- Q: Is it possible to use a lifting device to assist in lifting an individual who is too tall for one person to lift safely?

- <p>Yes, you can use a lifting device to assist in lifting someone who is too tall for you to lift alone. These devices are designed to help in safely moving individuals who are heavier or taller than can be managed without assistance. It's important to ensure that the lifting device is appropriate for the person's weight and height, and that it is used correctly to avoid injury. Always follow the manufacturer's instructions and safety guidelines when using such equipment.</p>

- Q: This question asks about the procedures and practices for regularly maintaining and inspecting a building hoist to ensure its safe and efficient operation.

- <p>Regular maintenance and inspection of a building hoist are crucial for safety and efficiency. It involves daily checks before use, including visual inspections for any visible damage, proper functioning of safety devices, and ensuring the hoist is clean and free of debris. Weekly inspections should focus on the mechanical components, such as gears, cables, and brakes, and checking for any unusual noises or vibrations. Monthly inspections may include more in-depth checks of the electrical systems and the structural integrity of the hoist. Annual inspections typically involve a thorough examination by a certified professional, who will assess the overall condition and safety of the hoist, ensuring it complies with all relevant safety standards. Always follow the manufacturer's guidelines and local regulations for maintenance and inspection schedules.</p>

- Q: This question asks for the procedure to safely lower an object after it has been lifted using a building hoist.

- <p>To safely lower an object after using a building hoist, ensure that the area below is clear of people and obstacles. Slowly release the hoist's brake or control mechanism, allowing the object to descend gradually. Keep a steady hand on the controls to maintain a controlled descent. Monitor the object's position and communicate with ground personnel if necessary. Ensure all safety hooks and attachments are secure until the object reaches the ground. Once the object is safely on the ground, secure it and disconnect it from the hoist. Always follow the manufacturer's guidelines and safety protocols for the specific hoist being used.</p>

- Q: How to adjust the weight limit of the construction elevator

- You're not going to be without a master You still look at the instructions

- Q: What is the need for the sc200/200 construction elevator cable?

- The sc200/200 construction elevator cable line should not be below 120 square. Man's ladder 33KW, 5 * 33 = 165KW The tower is 45KW one, 2 * 45 = 90KW The pressure slag welder is estimated to be 25KW Touch welder 1OKW, 5 * 10 = 50KW Other facilities such as mixer, temporary illumination etc. 30KW Total power: 165 + 90 + 25 + 50 + 30 = 365KW One square cable is 5 minus 7A, 380V is 1KW is equal to 2A. That's 730A 730A divided by 5-7 calculates that the cable line should not be less than 120 square.

Send your message to us

Building Hoist SC300 3-phase spare parts

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords