Building Hoist SC100/100 Construction Hoists for Sale

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Construction Hoist Description

The construction hoist product produced by Fangyuan has achieved internationally advanced level in terms of industrial design, control and the drive performance, as well as the operation safety and comfortableness. And Fangyuan is also making efforts to keep improving the product, as what the construction hoist lifts is not only people and material, but also a kind of social responsibility and service concept…

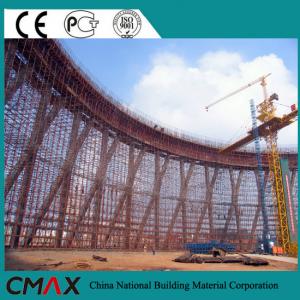

The new generation SC series of construction hoists adopt modular structure, ergonomic design and advanced manufacturing technology, thus the adaptability and reliability of the product is greatly improved, e.g. the max. lifting height can reach 300 meters. The product adopts multiple patented technologies, reaches advanced level in China, and the market share in domestic market is increasing year by year. The product has also been exported to overseas countries like Russia, Turkmenstan, Vietnam, etc. winning the confidence of customers of both home and abroad

Main features of Construction Hoist

1. The cage drive system is equipped with buffering device, so the cage moves more stable.

2. The ergonomically designed cage interior improves comfortableness.

3. The unique structural design has applied for patent.

4. The typical technologies ensure the malposition difference of the guide rail.

5. The excellent parts in the industry ensures reliable quality of the machine.

6. Precise assembly and accurate drive.

7. Professional solutions for special projects.

8. The complete safety devices ensures reliable control system.

Construction Hoist Specifiction

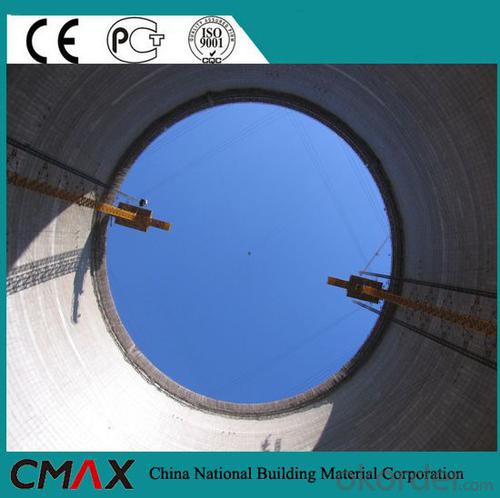

SC series product also has special design, such as reinforced guide rail with cross-section of 800mm, inclined type, special for cooling tower, etc. All the double cage construction elevator can be changed into single cage type, such as SCD200.

Model | SC200/200 | SC200/200BP | SCD200/200 | SC200/200B | ||

Configuration | Standard type | Frequency conversion | Counterweight type | Export type | ||

Rated load | kg | 2000/2000 | 2000/2000 | 2000/2000 | 2000/2000 | |

Cage size L×W×H | m | 3×1.3×2.2 | 3×1.3×2.2 | 3×1.3×2.2 | 3×1.3×2.2 | |

Passengers | 16/16 | 16/16 | 16/16 | 16/16 | ||

Max.lifting height | m | 150 | 300 | 150 | 150 | |

Max.height of free end | m | 9 | 9 | 9 | 9 | |

Lifting speed | m/min | 33 | 0~60 | 33 | 33 | |

Capacity of small hoist | kg | 200 | 200 | 200 | 200 | |

Std.section L×W×H | mm | 650×650×1508 | ||||

Electric motor | Type | Disc brake electic motor | ||||

Power | kW | 11×3/11×3 | 11×3/11×3 | 11×2/11×2 | 11×3/11×3 | |

Speed limiter | Action speed | m/s | 1.2 | 1.45 | 1.2 | 1.2 |

Rated brake load | kN | 40 | 40 | 30 | 40 | |

Model | SCD200/200B | SC100/100 | SCD200 | ||

Configuration | Counterweight type | No counterweight | Counterweight type | ||

Rated load | kg | 2000/2000 | 1000/1000 | 2000 | |

Cage size L×W×H | m | 3×1.3×2.2 | 3×1.3×2.2 | 3×1.3×2.2 | |

Passengers | 16/16 | 12/12 | 16 | ||

Max.lifting height | m | 150 | 150 | 150 | |

Max.height of free end | m | 9 | 9 | 9 | |

Lifting speed | m/min | 33 | 33 | 33 | |

Capacity of small hoist | kg | 200 | 200 | 200 | |

Std.section L×W×H | mm | 650×650×1508 | |||

Electric motor | Type | Disc brake electic motor | |||

Power | kW | 11×2/11×2 | 11×2/11×2 | 11×2 | |

Speed limiter | Action speed | m/s | 1.2 | 1.2 | 1.2 |

Rated brake load | kN | 30 | 30 | 30 | |

The above parameters are subject to change without prior notice, please refer to the actual product.

Note: Both cage size of 3×1.3×2.2 and 3.2×1.5×2.4 are available for of each model (Excl. export type).

Images of construction hoist

- Q: Construction elevator positioning should consider which problems

- The construction elevator is short for construction. It is an important equipment in high-rise building construction, and construction site accident hazards easily, because it can cause many major accidents, injuries in the inspection should be listed as a key to check the content. Based on past accidents and on-site inspections, we often find topics that we think should be examined in a critical area

- Q: The construction elevator always jumps

- Possible causes include: 1, the area that has broken skin in the line, leak the electric trip. There's something wrong with the switch Loose contact points in the line, and bad contact may also jump. It is best to do a thorough examination before closing the lock, and the forced closing is dangerous

- Q: Explain the benefits and drawbacks of using an electric winch compared to a building hoist.

- <p>Advantages of using an electric winch include ease of operation, lower noise levels, and the ability to be used in various environments. They are also more portable and can be easily moved between different locations. Disadvantages include higher initial costs compared to some building hoists, potential electrical hazards, and the need for regular maintenance to ensure safety. Additionally, electric winches may have lower lifting capacities compared to some building hoists, which could be a limitation for heavy construction tasks.</p>

- Q: This question asks for examples of typical uses for building hoists, which are devices used to lift materials in construction settings.

- <p>Building hoists are commonly used in various construction applications. They are utilized for lifting and lowering materials and personnel in high-rise construction projects. Some examples include: 1) Lifting building materials such as bricks, cement, and steel beams to different floors of a building under construction. 2) Transporting workers to elevated work areas for tasks like scaffolding assembly or window installation. 3) Moving heavy equipment to upper levels of a structure. 4) Assisting in the installation of large fixtures like HVAC systems or electrical wiring systems. 5) Facilitating the removal of construction waste from upper floors. These applications highlight the versatility and efficiency of building hoists in construction projects.</p>

- Q: This question asks for a comparison of the benefits and drawbacks of utilizing hydraulic fluids in lifting machinery.

- <p>The advantages of using hydraulic fluids in lifting equipment include their ability to transmit power efficiently, provide smooth and controlled movements, and absorb shock and vibration. They also have a high power-to-weight ratio, which is beneficial for lifting heavy loads. Additionally, hydraulic systems are relatively simple to maintain and can operate in a wide range of temperatures. Disadvantages include the potential for leaks, which can be hazardous and costly, and the need for regular maintenance to prevent system failure. Hydraulic fluids can also be environmentally harmful if not disposed of properly, and they may require specific storage conditions to prevent degradation.</p>

- Q: This question asks for a comparison between electric and hydraulic building hoists, highlighting their main differences.

- <p>Electric building hoists are powered by electricity and use electric motors to lift and lower loads. They are generally quieter, require less maintenance, and can be more energy-efficient. Hydraulic building hoists, on the other hand, use hydraulic pressure to move loads. They tend to be more powerful and can lift heavier loads, but they may require more maintenance and are not as energy-efficient. Electric hoists are often preferred for lighter loads and indoor use, while hydraulic hoists are chosen for heavy-duty applications and outdoor use where power is not readily available.</p>

- Q: Is it possible to use a building hoist for lifting heavy materials that cannot be manually lifted?

- <p>Yes, a building hoist is specifically designed for lifting heavy materials that are too heavy or cumbersome to lift manually. These hoists are engineered to handle significant weight loads and are commonly used in construction settings to move materials such as bricks, cement, and steel beams to various levels of a building. They are an essential tool for safe and efficient material handling in construction projects.</p>

- Q: What are the necessary safety rules and regulations that must be followed when operating a building hoist?

- <p>Safety regulations for using a building hoist include ensuring that the hoist is regularly inspected and maintained by qualified personnel. Operators must be trained and certified. The hoist should be equipped with safety devices such as limit switches, overload protection, and emergency stop buttons. Loads should never exceed the hoist's capacity, and the hoist should not be used in adverse weather conditions. Proper communication procedures must be followed, and a safety zone should be established around the hoist to prevent unauthorized access. Workers must wear appropriate personal protective equipment, and all safety guards and barriers must be in place and functioning correctly. Compliance with local and national regulations is also mandatory.</p>

- Q: What are the necessary steps and checks required to maintain a building hoist to ensure its safe and efficient operation?

- <p>Building hoists require regular maintenance to ensure safety and efficiency. This includes daily inspections of the hoist's mechanical and electrical components for any signs of wear or damage. Monthly, a thorough inspection should be conducted by a qualified technician, including checking the hoist's cables, brakes, and safety devices. Lubrication of moving parts and replacement of worn components are also crucial. Annually, a comprehensive inspection and certification by a professional is necessary to comply with safety regulations. Adherence to the manufacturer's guidelines is essential, and any malfunctions should be addressed immediately to prevent accidents.</p>

- Q: Is it possible for a hydraulic cylinder in a building hoist to experience leakage or failure?

- <p>Yes, a hydraulic cylinder in a building hoist can leak or break. Leaks can occur due to worn seals, damaged hoses, or corroded cylinder walls. Breakage may result from excessive pressure, manufacturing defects, or metal fatigue. Regular maintenance and inspection are crucial to detect and prevent such issues, ensuring the safety and efficiency of the hoist system.</p>

Send your message to us

Building Hoist SC100/100 Construction Hoists for Sale

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords