Building Hoist SCD200/200B Construction Hoists for Sale

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Main features of Construction Hoist

1. The cage drive system is equipped with buffering device, so the cage moves more stable.

2. The ergonomically designed cage interior improves comfortableness.

3. The unique structural design has applied for patent.

4. The typical technologies ensure the malposition difference of the guide rail.

5. The excellent parts in the industry ensures reliable quality of the machine.

6. Precise assembly and accurate drive.

7. Professional solutions for special projects.

8. The complete safety devices ensures reliable control system.

Construction Hoist Specification

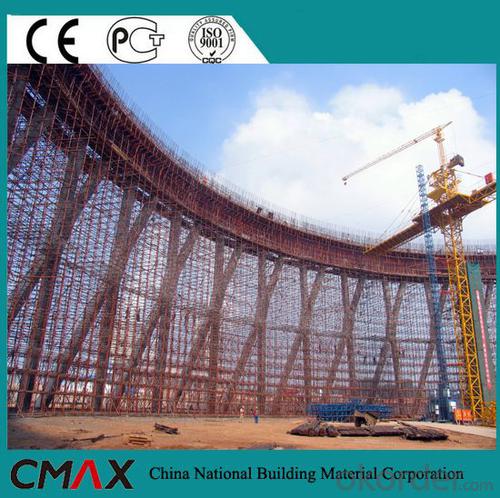

SC series product also has special design, such as reinforced guide rail with cross-section of 800mm, inclined type, special for cooling tower, etc. All the double cage construction elevator can be changed into single cage type, such as SCD200.

Model | SC200/200 | SC200/200BP | SCD200/200 | SC200/200B | ||

Configuration | Standard type | Frequency conversion | Counterweight type | Export type | ||

Rated load | kg | 2000/2000 | 2000/2000 | 2000/2000 | 2000/2000 | |

Cage size L×W×H | m | 3×1.3×2.2 | 3×1.3×2.2 | 3×1.3×2.2 | 3×1.3×2.2 | |

Passengers | 16/16 | 16/16 | 16/16 | 16/16 | ||

Max.lifting height | m | 150 | 300 | 150 | 150 | |

Max.height of free end | m | 9 | 9 | 9 | 9 | |

Lifting speed | m/min | 33 | 0~60 | 33 | 33 | |

Capacity of small hoist | kg | 200 | 200 | 200 | 200 | |

Std.section L×W×H | mm | 650×650×1508 | ||||

Electric motor | Type | Disc brake electic motor | ||||

Power | kW | 11×3/11×3 | 11×3/11×3 | 11×2/11×2 | 11×3/11×3 | |

Speed limiter | Action speed | m/s | 1.2 | 1.45 | 1.2 | 1.2 |

Rated brake load | kN | 40 | 40 | 30 | 40 | |

Model | SCD200/200B | SC100/100 | SCD200 | ||

Configuration | Counterweight type | No counterweight | Counterweight type | ||

Rated load | kg | 2000/2000 | 1000/1000 | 2000 | |

Cage size L×W×H | m | 3×1.3×2.2 | 3×1.3×2.2 | 3×1.3×2.2 | |

Passengers | 16/16 | 12/12 | 16 | ||

Max.lifting height | m | 150 | 150 | 150 | |

Max.height of free end | m | 9 | 9 | 9 | |

Lifting speed | m/min | 33 | 33 | 33 | |

Capacity of small hoist | kg | 200 | 200 | 200 | |

Std.section L×W×H | mm | 650×650×1508 | |||

Electric motor | Type | Disc brake electic motor | |||

Power | kW | 11×2/11×2 | 11×2/11×2 | 11×2 | |

Speed limiter | Action speed | m/s | 1.2 | 1.2 | 1.2 |

Rated brake load | kN | 30 | 30 | 30 | |

The above parameters are subject to change without prior notice, please refer to the actual product.

Note: Both cage size of 3×1.3×2.2 and 3.2×1.5×2.4 are available for of each model (Excl. export type).

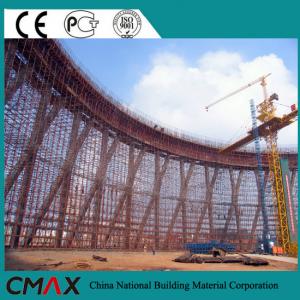

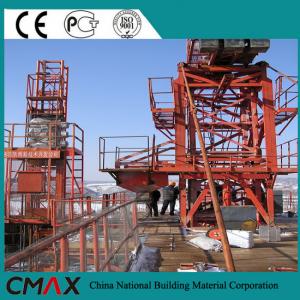

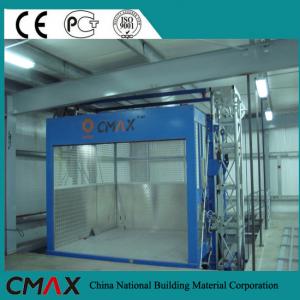

Images of construction hoist

FAQ of Construction Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide & protection system, electrical top crane and safety device.

- Q: What is the typical maintenance requirement for a building hoist?

- <p>The maintenance requirement for a building hoist can vary depending on the specific model and usage frequency. Generally, daily checks are needed to ensure safety, including inspecting cables, brakes, and the hoist mechanism. Monthly inspections should be conducted to check for wear and tear, and to lubricate moving parts. Annual inspections by a certified professional are often required to ensure compliance with safety standards and to perform more in-depth maintenance. Regular maintenance is crucial to prevent accidents and extend the lifespan of the hoist.</p>

- Q: This question seeks to understand the benefits and drawbacks associated with the use of hydraulic building hoists in construction.

- <p>Hydraulic building hoists offer several advantages, including high lifting capacity, smooth and controlled lifting, and lower maintenance costs due to fewer moving parts. They are also energy-efficient and can be easily integrated into existing systems. However, they have some disadvantages. For instance, they can be more expensive to purchase initially compared to other hoist types. Additionally, they may require more space for installation and can be sensitive to extreme temperatures, which might affect performance. Lastly, hydraulic systems can be prone to leaks and require regular fluid checks and maintenance to prevent system failure.</p>

- Q: This question asks for an explanation of the working mechanism of a building hoist, which is a device used in construction to lift materials and workers.

- <p>A building hoist, also known as a construction hoist or personnel/material hoist, is a temporary lifting device used in construction projects to transport workers and materials vertically within a building. It typically consists of a tower, a cage, a drive mechanism, and a control system. The tower is attached to the building's structure, and the cage is where people or materials are loaded. The drive mechanism, often powered by an electric motor, raises and lowers the cage along the tower. The control system manages the movement, ensuring safety features like speed control and emergency stops are in place. The hoist operates within a guide rail system, which keeps it aligned as it moves up and down the building's height.</p>

- Q: This question asks for guidance on the upkeep and repair procedures for a building hoist, a mechanical device used for lifting materials in construction.

- <p>To maintain and repair a building hoist, follow these steps: Ensure regular inspections by qualified personnel, checking for wear and tear, and addressing any issues promptly. Lubricate moving parts as per the manufacturer's guidelines to reduce friction and prolong component life. Replace worn-out cables, pulleys, and other critical components to prevent accidents. Keep the hoist clean and free from debris to prevent jams and malfunctions. For repairs, always consult the manufacturer's manual or hire professional technicians to avoid safety hazards. Regular maintenance and prompt repair are crucial for the safe operation of building hoists.</p>

- Q: Is it possible for a building hoist to simultaneously lift and lower various materials?

- <p>Yes, a building hoist can be used to raise and lower different materials at the same time, provided it has the necessary capacity and the materials are properly secured. This is often done by using multiple hooks or platforms, each designated for different materials. It's crucial to ensure that the combined weight does not exceed the hoist's load limit and that safety protocols are strictly followed to prevent accidents.</p>

- Q: What are the necessary conditions and safety measures to be met when using a building hoist to lift heavy objects?

- <p>Lifting heavy objects with a building hoist requires adherence to several key requirements for safety and efficiency. These include ensuring the hoist is properly installed and inspected, the load is secured correctly, and the weight does not exceed the hoist's capacity. Operators must be trained and certified, and they should follow all safety protocols. The area around the hoist should be clear of obstructions and bystanders. Regular maintenance and checks are crucial to prevent accidents. Additionally, weather conditions, such as high winds, can affect the safety of hoist operations and may require postponing lifts until conditions improve.</p>

- Q: This question asks if a building hoist is capable of lifting objects that vary in size and weight.

- <p>Yes, a building hoist can be used to lift objects of different sizes and weights, but it is crucial to ensure that the hoist's capacity is suitable for the load. Building hoists are designed to handle various materials and equipment during construction, and their lifting capacity can range from a few hundred pounds to several tons. It is essential to check the hoist's specifications and adhere to the maximum load limit to ensure safety and prevent damage to the hoist or the objects being lifted. Always follow the manufacturer's guidelines and safety standards when operating a building hoist.</p>

- Q: Is the construction elevator the same as the construction elevator

- Construction elevators are often called construction elevators, but construction lifts include a broader definition, and construction platforms are part of the construction elevator series. Simple construction elevator is by car, driving mechanism, standard section, attached to the wall, chassis, fence, electrical system and so on several parts, manned cargo construction machinery is a frequently used in construction, because of its unique enclosure structure make it take up both comfort and safety, construction elevator is usually used with tower crane on the construction site, the average load in 1-5 tons, running speed is 1 to 60 m/min.

- Q: Is it possible to utilize a building hoist for the purpose of raising construction materials or machinery?

- <p>Yes, a building hoist is specifically designed for lifting materials and equipment in construction settings. It is a temporary vertical transportation system used to move materials, tools, and sometimes personnel between different floors of a building under construction. Building hoists are essential for efficient construction processes, ensuring that materials are delivered to the correct levels without the need for manual labor, which can be time-consuming and hazardous.</p>

- Q: This question asks for a guide on how to properly and effectively install lifting equipment to ensure safety and efficiency.

- <p>To install lifting equipment safely and efficiently, follow these steps: 1. Ensure the equipment is suitable for the load and environment. 2. Check all safety features and documentation. 3. Position the equipment on a stable, level surface. 4. Follow the manufacturer's installation guide precisely. 5. Conduct a thorough inspection before operation. 6. Train operators on safe usage. 7. Regularly maintain and inspect the equipment. Remember, safety is paramount, and adherence to guidelines is crucial to prevent accidents and ensure efficient operation.</p>

Send your message to us

Building Hoist SCD200/200B Construction Hoists for Sale

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 20 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords