Building Hoist SC 200 Sing Cage with CE ISO Certificate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

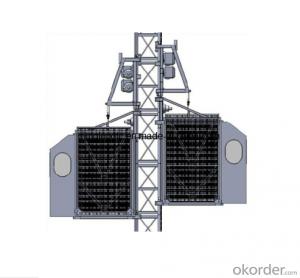

Structure of Building Hoist

SC200/200 Construction Elevator

Robot Welding Mast Section

Impeller Blasting System, SAJ device

Six Motors, Schneider Contactor

SC200/200 Construction Elevator

Main characteristic of construction hoist:

1. The mast sections of construction hoist adopt welding robot to weld, reliable in price and elegant in appearance

2. All the structure adopt reaming impeller blasting technolog, the adhension of surface painting is good

3. Cage guarding board adopts flower aluminous board and numerical controlling punching aluminous board, the weight of cage is light, elegant and beautiful in appearance.

4. Professional manufacturer provide the transmission gear, high mechanical efficiency, extended service life, steady performance.

5. Overload protection and variety of limiter are reliable and complete, optimal safety device select SAJ40-1.2, which restricts the excessive downward movement of the cage and prevents cage falling accidents.

6. Variable-frequency construction elevator are safe \stead \comfort, start electricity is smaller then the working electricity, efficient and efficient

Building hoist Specifiction

| Elvator classification | Model | Rated load capacity(kg) | Lifing speed (m/min) | Motor power (kw) | Rated fixing load capacity (kg) | Balanced weight capacity | Dimension inside cage(length*width*height) | ||

| Normal frequency construction elevator | single cage | Balanced weight | SCD200 | 2000 | 33 | 2× 11 | 1000 | 1000 | 3.0× 1.3× 2.4 |

| Unbalanced weight | SC200 | 2000 | 33 | 3× 11 | 2000 | 0 | 3.0× 1.3× 2.4 | ||

| SC100 | 1000 | 33 | 2× 11 | 1000 | 0 | 2.5× 1.3× 2.4 | |||

| double cage | Balanced weight | SCD200/200 | 2× 2000 | 33 | (2× 2)× 11 | 2× 1000 | 21000 | 3.0× 1.3× 2.4 | |

| Unbalanced weight | SC100/100 | 2× 1000 | 33 | (2× 2)× 11 | 2× 1000 | 0 | 2.5× 1.3× 2.4 | ||

| SC200/200 | 2× 2000 | 33 | (2× 3)× 11 | 2× 2000 | 0 | 3.0× 1.3× 2.4 | |||

| Frequency construction elevator | single cage | Balanced weight | SCD200 | 2000 | 0-63 | 3× 15 | 1000 | 1000 | 3.0× 1.3× 2.4 |

| Unbalanced weight | SC200 | 2000 | 0-63 | 3× 15 | 2000 | 0 | 3.0× 1.3× 2.4 | ||

| SC100 | 1000 | 0-63 | 3× 11 | 1000 | 0 | 2.5× 1.3× 2.4 | |||

| double cage | Balanced weight | SCD200/200 | 2× 2000 | 0-63 | (2× 3)× 15 | 2× 1000 | 2× 1000 | 3.0× 1.3× 2.4 | |

| Unbalanced weight | SC100/100 | 2× 1000 | 0-63 | (2× 3)× 11 | 2× 1000 | 0 | 2.5× 1.3× 2.4 | ||

| SC200/200 | 2× 2000 | 0-63 | (2× 3)× 15 | 2× 2000 | 0 | 3.0× 1.3× 2.4 | |||

Building Hoist Images

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the dimension of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance

& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience

- Q: Is it possible to fix a building hoist or substitute it with alternative lifting machinery?

- <p>Yes, a building hoist can be repaired if the damage is not severe. If repair is not feasible or cost-effective, it can be replaced by other types of lifting equipment. There are various alternatives available, such as cranes, forklifts, and material hoists, each with its own advantages and suitable for different scenarios. The choice depends on factors like the weight of the load, the height of the building, and the specific requirements of the construction project. It's essential to consider safety, efficiency, and compatibility with the existing infrastructure when making such decisions.</p>

- Q: The difference between the derrick and the construction elevator?

- Derrick is with the hoist rope hoisting, referred to as goods for SSB100 type, with construction lifter model does not allow the manned, deadweight is one tons, construction lifter is said cargo amphibious ladder, with gear and rack driving, weight is 2 tons, you can have a look at the GB/T 10054-2005, the construction lifter, with clear rules.

- Q: This question asks whether a hydraulic building hoist can be used in both indoor and outdoor environments and seeks reasons for its versatility.

- <p>A hydraulic building hoist can be used both indoors and outdoors. These hoists are designed to be versatile and durable, capable of withstanding various weather conditions when used outdoors. They are also compact and can be easily maneuvered in indoor spaces. The primary reason for their versatility is the robust construction and the ability to handle different loads with precision. Additionally, hydraulic systems are less affected by electrical interference, making them suitable for environments with fluctuating power supplies. However, it's important to ensure that the hoist is properly maintained and protected from extreme weather conditions to prolong its lifespan and ensure safety.</p>

- Q: When does the construction elevator take off?

- If the elevator is installed later, can the construction elevator be demolished at this time? It should not be removed because the elevator is used by the local technical supervision bureau. The unused elevator will be fined 5-200, 000 fine and the elevator installation unit will be revoked. No one will take that risk! It is usually done on rooftops, indoors and outdoors, and the materials have been transported upstairs. It is best to be able to remove the elevator when it is finished, so it doesn't affect the progress.

- Q: Is it possible to employ a building hoist for demolition purposes?

- <p>While a building hoist is primarily designed for construction purposes, such as lifting materials and personnel to different floors, it is not typically recommended for demolition work. Demolition requires specialized equipment that can handle the specific stresses and hazards associated with breaking down structures. Using a building hoist for demolition could be dangerous and may not comply with safety regulations. It's crucial to use equipment specifically designed for demolition tasks to ensure the safety of workers and the effectiveness of the operation.</p>

- Q: Is it possible to use two lifting devices simultaneously to lift an object that is heavier than the maximum weight each device can handle individually?

- <p>Yes, two lifting devices can be used together to lift a heavier object than either one can handle alone, provided that both devices are capable of supporting the combined weight and are properly synchronized. This requires careful planning and coordination to ensure the safety of the operation and the integrity of the lifting devices. The total weight capacity of the combined system should be greater than the weight of the object being lifted, and the devices must be designed to work in tandem without overloading or causing damage.</p>

- Q: Is it possible to utilize a building hoist for the transportation of objects?

- <p>Yes, a building hoist is specifically designed for moving objects, particularly in construction settings. It is used to lift and lower materials and equipment vertically, making it ideal for moving heavy objects between different floors of a building under construction. Building hoists are engineered to handle the weight and size of various construction materials, ensuring efficient and safe transportation.</p>

- Q: Is it possible to fix or replace a building hoist once it has stopped functioning?

- <p>Yes, a building hoist can be repaired or replaced after it has failed. Repairs are often possible if the hoist has mechanical or electrical issues that can be diagnosed and fixed by a qualified technician. If the hoist is beyond repair or if it's more cost-effective, a replacement may be necessary. It's crucial to have a maintenance plan and regular inspections to prevent failures and ensure the hoist's safe operation. In case of a failure, immediate action should be taken to either repair the existing hoist or install a new one, adhering to safety standards and regulations.</p>

- Q: This question asks for the cost of a building hoist, which is a type of construction equipment used for lifting materials.

- <p>The cost of a building hoist can vary significantly depending on factors such as the hoist's capacity, type, and features. On average, a basic building hoist can cost anywhere from $10,000 to $50,000. However, for more advanced models with higher capacities or additional safety features, the price can range from $100,000 to $200,000 or even more. It's important to consider the specific needs of your construction project and consult with equipment suppliers for accurate pricing.</p>

- Q: Is the construction elevator the same as the construction elevator

- Construction lifter and building construction elevator, manned cargo construction machinery is a frequently used in construction, because of its unique enclosure structure make it take up both comfort and safety, construction lifter is usually used with tower crane on the construction site, the average load in 1-3 tons, running speed is 1 to 60 m/min. There are many kinds of elevators in construction, there are no two kinds of weights and weights in the way of operation, and they are controlled by manual control and automatic control. You can also add inverter and PLC control modules as needed, and also add floor calling devices to the peace layer. The structure principle and characteristics of construction lifter: construction lifter for meet the needs of the lean construction bridge, chimney, etc, it according to the building shape, install the guide frame tilt, and hanging basket level, along the inclined guide plane running up and down.

Send your message to us

Building Hoist SC 200 Sing Cage with CE ISO Certificate

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 1000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords