Building Hoist SC120/120 with ISO Certificate

- Loading Port:

- China main port

- Payment Terms:

- TT or LC or Cash

- Min Order Qty:

- 1 unit

- Supply Capability:

- 22 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Building Hoist Description

Product: Building Hoist Condition: standard or customized Usage: Material Lifting

Rated load(kg):2*1200 Lifting Speed(m/min):0~45 Motor Power(kw): 2*3*11

Safety Device: 2*SAJ30-1.4 Cage: Double Counterweight: No

Certification: CE,ISO Place of Origin: China(Mainland) Model Number: Type:SC120/SC120

Packaging & Delivery of Building Hoist

Packaging Method: Nude package Shipping Time: 25-30days

Main Components

● Mast section size can be 450x450x1508mm-alimak type. Also 650x650x1508mm is available. The steel is Baosteel. diameter of steel pipe is 76mm and thickness is 4.5, 6 and 8mm. The thickness of the pipe is determined by the height of the building.

● Cage can be galvanized and standard size is 3.2x2.5x1.5m.

● About motor, we have nord and China famous brand

● As for inverter, Yaskawa, Siemens and Schneider are available. Besides China famous brand inverter is available.

● The VF system also has the over voltage protection,low voltage protection, overcurrent, overload and anti-stalling protection functions,

● The system applies the special software for hoists developed by our company, making the operation more safe and

reliable.

Some optional devices such as landing door, calling system and auto-landing system are available

Building Hoist Pictures

CMAX Building Hoist

Mast Section

Nord Motor

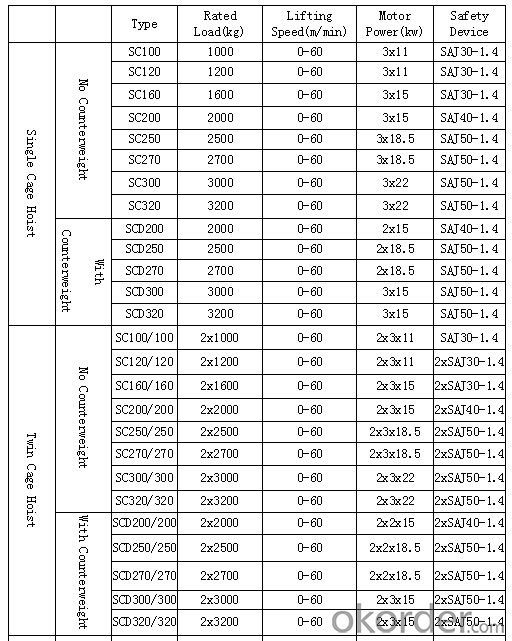

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the usgae of building hoist ?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in construction site.

Q: What is the building hoist consist of?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: How we define construction hoist?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

Q: What is the standard size of the cage?

A: Normally the cage dimension is 3X1.5X2.5M (L/W/H) for 2t type hoist. Details should be checked according to our

quotation sheet. Also, the size can be customized according to the factual site condition. There are two doors (entrance

& exit doors) for each cage, It can be produced as up & down sliding or ramping model for safety and convenience.

- Q: This question asks for a comparison of the pros and cons associated with the use of electric building hoists in construction.

- <p>Electric building hoists offer several advantages such as ease of operation, reduced manual labor, and increased efficiency in lifting and transporting materials. They are also safer compared to manual hoists, reducing the risk of accidents. Additionally, they can handle heavier loads and operate in various weather conditions. However, they have some disadvantages too. For instance, they require a power source and can be less reliable during power outages. They also involve higher initial costs and maintenance expenses. Electric hoists can be noisy, which may lead to noise pollution, and they can be complex to install and operate, requiring skilled personnel.</p>

- Q: This question asks for the method to adjust the tension of ropes or cables in lifting equipment such as a building hoist.

- <p>Adjusting the tension on ropes or cables in lifting equipment like a building hoist involves several steps. First, ensure the equipment is turned off and secured to prevent any accidents. Then, locate the tensioning mechanism, which could be a ratchet, turnbuckle, or a similar device. Gradually adjust the mechanism to tighten or loosen the cable as needed. Use a tension meter to measure the tension and ensure it meets the manufacturer's specifications. Regularly inspect the cables for wear and damage, and replace them if necessary. Always follow the equipment's manual for specific instructions and safety guidelines.</p>

- Q: This question asks for a comparison between manual and automatic lifting systems used in construction equipment, highlighting their distinct features and operational differences.

- <p>Manual lifting systems in construction equipment rely on human effort to lift and move materials. They are often less expensive, require less maintenance, and are suitable for lighter loads or smaller-scale projects. However, they are labor-intensive, can be slower, and pose higher risks of injury due to the physical demands. Automatic lifting systems, on the other hand, use mechanical or electronic means to lift and move materials. They are more efficient, can handle heavier loads, and reduce the risk of injury by minimizing manual handling. These systems are often more expensive and require regular maintenance but offer precision, speed, and ease of operation, making them ideal for large-scale construction projects.</p>

- Q: Is it possible to use a manual building hoist to lift multiple objects simultaneously?

- <p>Yes, a manual building hoist can be used to lift multiple objects at once, provided the total weight does not exceed the hoist's maximum load capacity. It's crucial to ensure that the hoist is securely attached to a stable structure and that all safety protocols are followed to prevent accidents. The objects should be evenly distributed and properly secured to the hoist to maintain balance and prevent tipping. Always refer to the manufacturer's guidelines for specific weight limits and safety instructions.</p>

- Q: This question asks for a description of the process of operating a building hoist using a remote control system.

- <p>To use a remote control system for a building hoist, first ensure that the hoist is properly installed and inspected for safety. Turn on the hoist's power supply and ensure the remote control is synced with the hoist. Familiarize yourself with the control panel, which typically includes buttons for up, down, stop, and emergency stop. Operate the hoist by pressing the up or down buttons to lift or lower the load. Always monitor the load's movement and communicate with workers on site. Use the stop button to halt the hoist if needed, and the emergency stop button in case of an immediate hazard. Regularly check the hoist's operation and maintain the remote control system to ensure smooth and safe operation.</p>

- Q: This question asks for the method to determine the maximum weight a building hoist can lift.

- <p>The lifting capacity of a building hoist is calculated by considering several factors including the hoist's motor power, the strength of the hoist's construction materials, and the safety factor. The manufacturer usually provides the maximum lifting capacity based on these factors. To calculate it manually, you would need to know the motor's lifting force, the efficiency of the hoist's mechanical system, and apply a safety factor to ensure the hoist operates within safe limits. It's important to follow the manufacturer's guidelines and never exceed the specified lifting capacity to prevent accidents and ensure the hoist's longevity.</p>

- Q: Does the new approach builder need a localizer test report

- When the distance of the meter cage is not more than the distance shown in the test, the safety device meets the requirements of the relevant specification. You're talking about a construction elevator that's the kind of gear rack that you don't want to have as long as you want to

- Q: How to adjust the weight limit of the construction elevator

- You're not going to be without a master You still look at the instructions

- Q: Is it possible to utilize building hoists for construction purposes?

- <p>Yes, building hoists are commonly used in construction work. They are essential for lifting and lowering materials, tools, and sometimes personnel between different floors of a building under construction. These hoists enhance efficiency by reducing manual labor and improving safety by minimizing the risk of accidents associated with manual handling of heavy loads. They are designed to be robust and reliable, making them a vital piece of equipment in the construction industry.</p>

- Q: What are the fundamental parts that make up a building hoist?

- <p>The basic components of a building hoist include the hoist machine, mast or tower, guide rails, lifting cage, counterweight system, safety devices, electrical control system, and communication system. The hoist machine powers the lifting and lowering of the cage, while the mast provides structural support. Guide rails ensure the cage moves vertically, and the counterweight balances the cage's weight. Safety devices protect against accidents, and the electrical control system manages operations. The communication system allows for coordination between the hoist operator and other construction personnel.</p>

Send your message to us

Building Hoist SC120/120 with ISO Certificate

- Loading Port:

- China main port

- Payment Terms:

- TT or LC or Cash

- Min Order Qty:

- 1 unit

- Supply Capability:

- 22 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords