Building Hoist 3200kg Single Cage Transportation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Building Hoist Description

Condition: New

Application: Construction

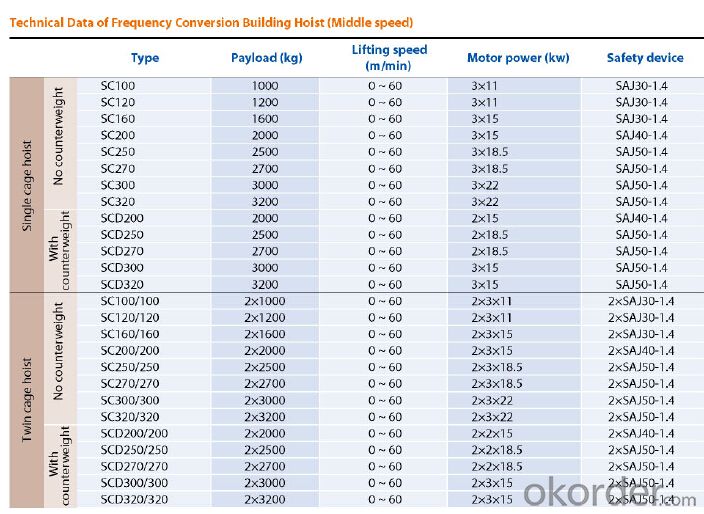

Payload(kg):3200

Lifting Speed(m/min):0~60

Motor Power(kw): 3*15

Safety Device: SAJ50-1.4

Cage: Single

Counterweight: Yes

Certification: CE,ISO

Place of Origin: China(Mainland)

Model Number: Type:SCD320

Packaging & Delivery of Building Hoist

Packaging Detail: Nude package

Delivery Detail: 25-30days

Features of Building Hoist

●Due to the strict raw material procurement control system, our drive motors for construction hoist/ building lift /material elevator for bridge/ tower / chimney / building is guaranteed with safe and reliable performance.

●The steel, electrical components, hoist cables, high strength bolts and spare parts are all introduced from well-known international and domestic suppliers.

●Adopts the most advanced VF speed control device and microcomputer programmable logic controller.

● Stepless speed control helps eliminate the concussion during start up and braking, steady the operation process,

and ensures automated leveling.

● Adopts open loop V/Fcontrol; the speed control precision can reach ±2~3%. Realizes accurate low speed positioning of the hoist and avoid slipping during downward stopping of hoist.

● The VF system has current-restriction function, ensuring a small current when motor start up and reducing the concussion to power supply. It reduces the engery consumption and mitigates effects to on site electric equipments.

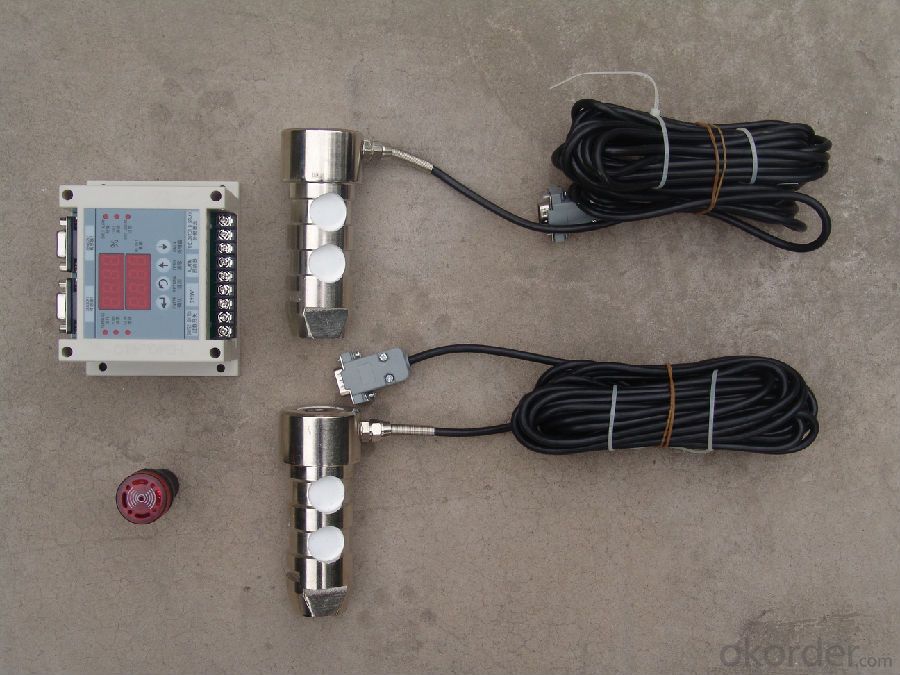

Building Hoist Images

Building Hoist Specifiction

FAQ of Building Hoist

Q: What is the building hoist main purpose?

A: Building hoist equipped with double or single cabin to transport the materials and labors up and down. It's the ideal

construction equipment for vertical transportation in the field of construction.

Q: What is the main structure of building hoist?

A: The P/M construction hoist mainly contains metal structure, driving system, electrical control system, cable guide &

protection system, electrical top crane and safety device.

Q: What is the meaning of the building hoist’s code?

A: Take SC200/200 for example: “SC” stands for rack and pinion hoist, “200/200” stands for double cage and capacity

is 2 tons per cage. “SC200” stands for single cage and capacity is 2 tons.

- Q: Is it permissible to use a building hoist for lifting people?

- <p>Building hoists are not designed for lifting people and doing so can be extremely dangerous. They are specifically engineered for the transportation of materials and equipment in construction settings. Using a building hoist to lift people violates safety regulations and can result in severe accidents. Always adhere to the manufacturer's guidelines and local safety laws, which prohibit the use of building hoists for carrying personnel.</p>

- Q: Explain how a lifting platform, specifically a building hoist, operates.

- <p>A building hoist, also known as a construction hoist, is a temporary lifting platform used in construction to lift materials and personnel vertically within a building under construction. It operates by using a motor-driven pulley system that runs on guide rails or tracks. The hoist is attached to the building structure and as the building grows, the hoist is extended upwards. The platform is loaded with materials or workers, and the operator controls the ascent or descent through an electrical switch or remote control. Safety features include limit switches to prevent over-travel, safety catches to stop the platform in case of a cable failure, and interlocks to ensure the platform cannot be operated when the doors are open.</p>

- Q: This question asks for the procedure to safely lower an object after it has been lifted using a building hoist.

- <p>To safely lower an object after using a building hoist, ensure that the area below is clear of people and obstacles. Slowly release the hoist's brake or control mechanism, allowing the object to descend gradually. Keep a steady hand on the controls to maintain a controlled descent. Monitor the object's position and communicate with ground personnel if necessary. Ensure all safety hooks and attachments are secure until the object reaches the ground. Once the object is safely on the ground, secure it and disconnect it from the hoist. Always follow the manufacturer's guidelines and safety protocols for the specific hoist being used.</p>

- Q: Is it feasible to repair or replace a building hoist with ease?

- <p>The ease of repairing or replacing a building hoist depends on several factors. For minor issues, repairs can often be done relatively easily by trained technicians. However, for major malfunctions or when a hoist is outdated, replacement might be necessary. This process can be complex and requires expertise to ensure safety and compliance with building codes. Factors such as the hoist's age, the complexity of the system, and the availability of replacement parts play a significant role in determining the ease of repair or replacement. In some cases, it might be more cost-effective to replace rather than repair, especially if the hoist is old or if repair costs are high.</p>

- Q: Is it possible to utilize a building hoist to lift objects with varying dimensions and weights?

- <p>Yes, building hoists are designed to lift a variety of objects with different sizes and weights. However, each hoist has specific weight and size limitations that must be adhered to for safety and operational reasons. It's crucial to ensure that the objects being lifted are within the hoist's capacity to prevent accidents and damage. Always consult the manufacturer's specifications and safety guidelines before using a hoist for lifting operations.</p>

- Q: This question asks about the precautions and safety protocols that should be followed when using lifting equipment in construction projects.

- <p>Safety measures for using lifting equipment in construction work include regular inspections and maintenance of the equipment, ensuring all safety features are in place and functioning correctly. Operators must be trained and certified for the specific type of lifting equipment they are using. Load limits should never be exceeded, and all loads must be secured properly. Safe operating procedures should be followed, such as not lifting loads over people and maintaining a safe distance from power lines. Personal protective equipment (PPE) must be worn by operators and workers in the vicinity. Emergency procedures should be established and communicated to all workers. Regular safety briefings and training sessions should be conducted to keep safety at the forefront of all operations.</p>

- Q: Can a single lifting device accommodate variously shaped and sized objects?

- <p>Yes, a single lifting device can often be used to lift objects of different shapes and sizes, provided it has the necessary capacity and adaptability. Adjustable features, such as extendable arms, variable hooks, or specialized attachments, allow for a range of lifting capabilities. However, it's crucial to ensure that the device's weight limit is not exceeded and that it is safe and suitable for the specific object being lifted to avoid damage or accidents. Always refer to the manufacturer's guidelines for the safe operation and weight limits of the lifting device.</p>

- Q: What types of materials can be transported using a building hoist?

- <p>A building hoist can lift a variety of materials, including construction supplies such as bricks, cement, sand, and gravel. It can also transport larger items like steel beams, prefabricated concrete elements, and heavy machinery. Additionally, it is used to move tools, equipment, and sometimes personnel within the construction site. The specific materials that can be lifted depend on the hoist's capacity and the safety regulations in place. It's crucial to ensure that the load does not exceed the hoist's weight limit to maintain safety standards.</p>

- Q: Is it possible to replace a motor in a building hoist with a hydraulic cylinder?

- <p>While a hydraulic cylinder can provide linear motion and force, it is not a direct substitute for a motor in a building hoist. Hydraulic cylinders are used for lifting and pushing applications, but they lack the variable speed and control that a motor provides. Motors, especially electric ones, offer precise control, variable speed, and efficiency which are critical for hoisting operations. A hydraulic system would require additional components like pumps and valves for control, making it more complex and less energy-efficient compared to an electric motor system. Therefore, a hydraulic cylinder alone is not suitable as a direct replacement for a motor in a building hoist.</p>

- Q: This question asks if a building hoist can be utilized in both commercial and residential settings.

- <p>Yes, a building hoist can be used for both commercial and residential purposes. These hoists are designed to lift materials and workers to various levels of construction sites. In commercial settings, they are often used in the construction of office buildings, shopping centers, and other large-scale projects. In residential construction, they are used for multi-story apartment buildings or private homes. It's important to note that the specific type and capacity of the hoist should be suitable for the scale and requirements of the project to ensure safety and efficiency.</p>

Send your message to us

Building Hoist 3200kg Single Cage Transportation

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 30 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords