BR800 Full sized Multi-color Sheet fed Press Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of BR800 Full sized Multi-color Sheet fed Press Machine:

It consists of zero-speed splicer, in feeder, printing unit of four cylinders, dryer, chill roll, silicon coater and folder. It can printing every kinds of commercial prints such as high quality color pages of newspaper, advertisement and so on.

2. Main Features of BR800 Full sized Multi-color Sheet fed Press Machine:

There is no driving shaft between the reel stand and the printing unit so that several equipments may be equipped, such as the Model JZ06880 Reel Stand of one paper roll made by our company or the Zero-speed Splicer, etc..

The web coming from the paper roll goes through a dancer roller mechanism which may reduce the negative influence to the web tension caused by defects of the paper roll itself.

Totally 8 control programs may be set according to the user’s need, which are suitable for different printing situations respectively.

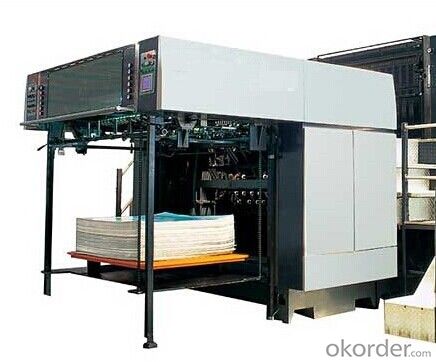

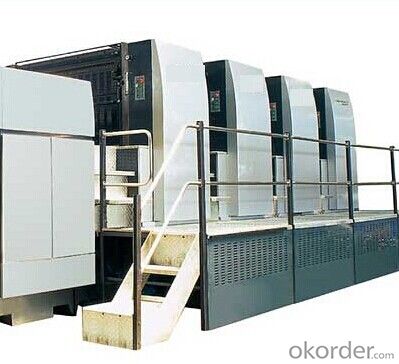

3.BR800 Full sized Multi-color Sheet fed Press Machine Images:

4.BR800 Full sized Multi-color Sheet fed Press Machine Specification:

Number Of Colors4

Max.Printing Speed(sph)8,000

Max.Sheet Size(mm2)1020×1420

Min.Sheet Size(mm2)650×920

Thickness Of Sheet(mm)0.10~0.60

Max.Printing Area(mm2)1010×1420

Plate Size(mm3)1440×1130×0.3

Blanket Size(mm3)1440×1350×1.9

Feeding Pile Height(mm)1200

Delivery Pile Height(mm)1400

Main motor power(Kw)55Overall

Dimensions(mm)13151×5250×3103

5.FAQ of BR800 Full sized Multi-color Sheet fed Press Machine:

We have organized several common questions for our clients,may help you sincerely:

1)How about your company?

A world class manufacturer & supplier can supply you good products for all worlds customer with high quality and competitive price

2)How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3)How long can we receive the product after purchase?

In the purchase of product within three working days, we will arrange the factory delivery as soon as possible. The specific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Where is secondhand corrugated paper packaging machinery available?

- Start a small yellow cardboard box factory, they have the best business, began the purchase of machinery, plant hire.In an unfamiliar field, we should listen to the opinions of experienced people.Carton is a supporting product of consumer products, so to speak, as long as people have consumption, enterprises and products, there will be no lack of product packaging.

- Q: The role of food packaging machinery

- Packaging is the necessary condition for products to enter the circulation field, and the main means of packaging is the use of packaging machinery. With the development of the times and the progress of technology, packaging machinery is playing a more and more important role in the field of packaging. The main functions of packaging machinery are as follows:

- Q: Vacuum packing machine for cooked food: can whole chicken, whole goose and whole duck be packed?

- Buddy, you go to Taobao to buy a few hundred vacuum packaging machine, the 3 days is no problem, I suggest you go to buy a good brand, this thing hundreds of, garbage is easy to bad, shelf life 3 days, basically no problem

- Q: The difference between wrapping and bagging is explained from the packaging method, and the difference of the working principle of the packaging machine is analyzed

- Wrapping of objects of different shapes according to their appearance.

- Q: Ask a mechanical problem, the waste film recycling in the packaging machinery is a new film packaging, after cutting, then use the roller to recycle the waste film. Encounter a

- It is recommended not to check the cursor, if the speed is stable, with the amount of speed (recommended to detect the angular speed of the drum) to detect, a closer speed will be smaller, you can do the implementation of the operation. If the speed is unstable, you can only use the scale. But the 2 one is marked out. The beginning and the end. A colleague detects the difference in velocity between the 2 displacements. The difference in speed means that the film is stretched and the excessive velocity is stopped directly, which means that the film has been stretched

- Q: What are the packing machines?

- They make packing equipment. There are many kinds of food packaging, sealing packaging, pillow type packaging machine. I hope I can help you.

- Q: What are the main functions of packaging machinery and equipment?

- Such as cleaning, stacking and disassembly. In addition, also includes the measurement or the package seal etc.

- Q: Is there anyone who knows what groups of users of packaging machinery are in general?

- If automated packaging, it depends on the factory situation, should not be from the user groups to start. If a small class of cosmetics do, then he will not say to buy a more than ten thousand or hundreds of thousands of automated equipment to pack ah. Automatic packing machine is certainly need a certain amount, a certain basis will be needed, or buy a mechanical automation a month the amount of packaging takes less than one hour, then buy this station automation machinery to do what? So, according to the automatic device, we can not start from the user groups, should be considered from the size of the factory.

- Q: Food, equipment, tools, containers, packaging materials, etc. shall comply with food safety standards or requirements

- Hygienic standard for polyethylene terephthalate resin for GB 13114 food containers and packaging materialsGB, 13113-1991. Hygienic standard for polyethylene terephthalate molded articles for food containers and packaging materials

- Q: Donkey hide gelatin cake made of sticky, forming very well, that is, vacuum packaging, after a little sticky in the vacuum bag, what's going on?

- Personal advice:In this respect, I suggest you look for the factory in Dongguan, Tangxia, which is the base of vacuum bag production. By logistics or express delivery, the goods will be delivered soon!!

Send your message to us

BR800 Full sized Multi-color Sheet fed Press Machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords