Bottoom Gusset Zipper Closer Kraft Paper Laminated Bags

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Bottoom Gusset Zipper Closer Kraft Paper Laminated Bags:

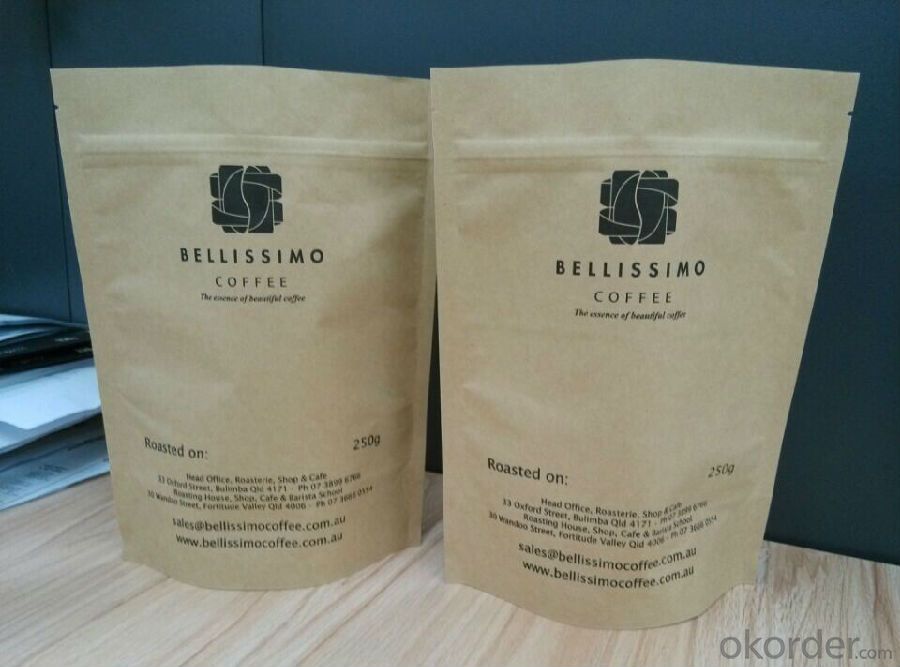

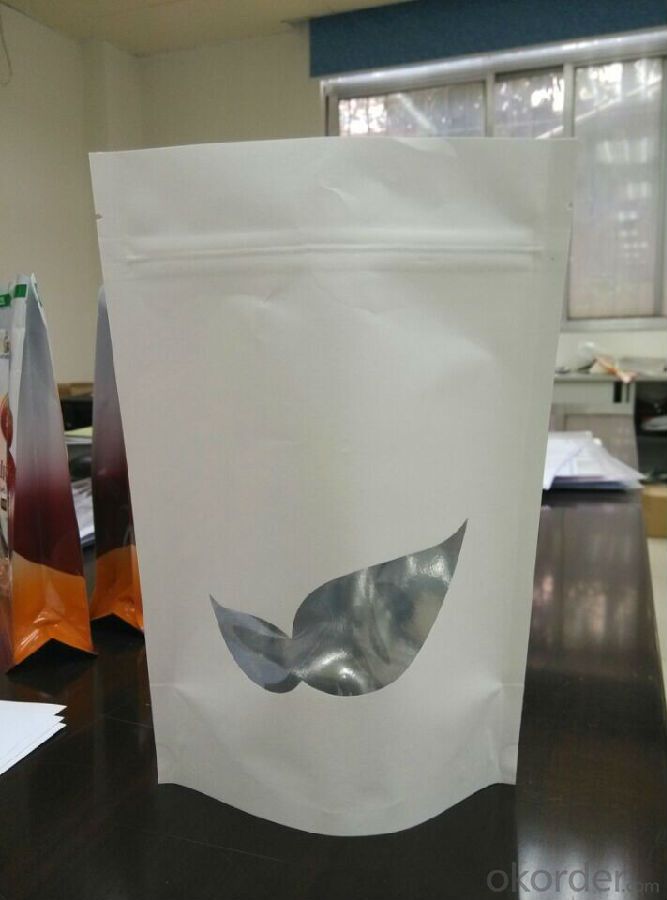

Bottoom Gusset Zipper Closer Kraft Paper Laminated Bags are processing with imported materials,we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Bottoom Gusset Zipper Closer Kraft Paper Laminated Bags mainly used for packing food such as coffee, tea, snack, powder etc.

2. Main Features Bottoom Gusset Zipper Closer Kraft Paper Laminated Bags:

Excellent quality control

Experienced facotry produced

SGS passed

3. Bottoom Gusset Zipper Closer Kraft Paper Laminated Bags Photos:

4. Bottoom Gusset Zipper Closer Kraft Paper Laminated Bags Specification:

1. Material: PE,LDPE,HDPE with Craft paper etc

2.Size:10*10000px or Customized

3.Thickness:10-200um

5.FAQ of Bottoom Gusset Zipper Closer Kraft Paper Laminated Bags:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: Duck sauce made of pure aluminum foil vacuum packaging bag or transparent plastic?

- PET thin film / foil / nylon //PE thin film, it is best for the duck packaging, the longest period of hedging. Of course, there are some other place form, slightly reduce some costs, such as the PET// //PE aluminum foil film, but the effect was not as good as the former good bag, a bag to reduce the cost of not much, but the effect is significantly reduced, so it is recommended to use the former.

- Q: What are the characteristics of a good package?

- According to the statistics of the foreign trade department, because of the backward packaging of export commodities, China has reduced the foreign exchange earnings by at least 10% per year. This shows that the good packaging design for the importance of national economic development.

- Q: Can food wrap be heated in a microwave oven?

- There are two sides to consider1. sealed pockets are heated in a microwave oven, and the pressure in the bag is too large to explode! There are all the instructions on the microwave (as well as the eggs, and a hole). The microwave food I eat is also packed in plastic bags, but there's always room for gas2. material of packing bagGeneral contact with food bags, requirements are made of polyethylene (non-toxic, burning candles oil smell), general temperature 130 degrees, this pocket no problem (including the regular supermarket to buy plastic wrap and plastic wrap)However, there are a lot of cheap pocket (for example in the market and vest bag, supermarket cashier for plastic bags) are made of PVC, and can not contact with recycled plastic food; do not to mention (characteristics: cheap, taste, burning acrid smell)And, if it's made of polyethylene, don't heat it up with high oil food

- Q: What material is the vacuum packing bag, please?

- And also consider the content and weight of the package to determine the reasonable use of the packaging materials. There is no static, and the right is the best.

- Q: The vacuum packing bag is sealed. How can I open the zipper?

- In addition to wax, you can also use lubricating oil, to pick a relatively transparent, clean kind of, in the zipper ring drop a few drops, repeated several times, can also achieve smooth purposes.

- Q: How much is the 1 wire in the food packing bag printing industry?

- 1 wire =0.01 mm, refers to the thickness of the bag units!

- Q: The shelf life of the package usually takes several forms

- Food soft packing materials mainly include polyethylene, polypropylene, polyester, polyamide and other polymer materials. These packing materials show great differences because of their molecular structure, forming process and additives. Therefore, for food manufacturers, choose a suitable packaging for their products is particularly important, otherwise there will be food safety issues.

- Q: The difference between a vacuum and a vacuum in a food package

- And packaging techniques like inflatable bags are called inflatable.

- Q: What does "13 silk" in vacuum packing bag mean?

- The vacuum packing bag 13 silk refers to the vacuum packing bag's thickness is 0.13 millimeters.

- Q: Printing solvent for food packing bag

- Use a moisture indicator to determine the content in the solvent. The water indicator is put into the solvent, and the water content varies with different colors. Depending on the color change, the amount of water in the solvent can be roughly determined.

Send your message to us

Bottoom Gusset Zipper Closer Kraft Paper Laminated Bags

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords