Bottom Gusset Zipper Closer Kraft Paper Laminated Bags

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of Bottom Gusset Zipper Closer Kraft Paper Laminated Bags:

Bottom Gusset Zipper Closer Kraft Paper Laminated Bags are processing with imported materials,we have introduced advanced equipment and high manufacturing technology into production lines and we have rich experience in producing plastic bag .can meet your needs by fulfilling your specification in a positive manner .High efficiency and speed are our working style .high quality and competitive price are our pursuit.

Bottom Gusset Zipper Closer Kraft Paper Laminated Bags mainly used for packing food such as coffee, tea, snack, powder etc.

2. Main Features Bottom Gusset Zipper Closer Kraft Paper Laminated Bags:

Excellent quality control

Experienced facotry produced

SGS passed

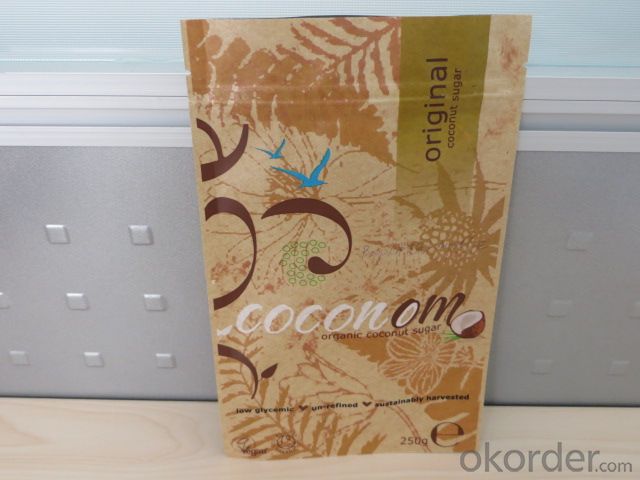

3. Bottom Gusset Zipper Closer Kraft Paper Laminated Bags Photos:

4. Bottom Gusset Zipper Closer Kraft Paper Laminated Bags Specification:

1. Material: PE,LDPE,HDPE with Craft paper etc

2.Size:10*10000px or Customized

3.Thickness:10-200um

5.FAQ of Bottom Gusset Zipper Closer Kraft Paper Laminated Bags:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Plastic packing bags can supply you all kind of packing bags you wanted.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers. Commonly 7 to 10 working days can be served.

- Q: How to evaluate the quality of a food packaging bag design? From what angle?

- Most importantly, the design of this package has a direct sensory connection to this product. Let's take a simple example, moon cake, which is a more common packing, is packed in a plastic bag and can only buy a few dollars, but it will appreciate a lot more when it is put into the gift box. It's in the bag. Moon cake is just food. In the gift box, it becomes a gift. Before consumers buy, the product is analyzed as a food or a gift, which is the most important message that the mooncake package conveys to the consumer.

- Q: What is the material of detergent bag?

- Most of these bags are made of PP, PE, OPP, BOPP plastic raw materials. In general, families rarely recycle, just waste or garbage.

- Q: How do I remove the self-adhesive label affixed to the plastic bag?

- On the label with wind, a few minutes to unveil the label, the label will fall together with adhesive. Even at the stubborn stickers with traces of essential balm, and fingernails pull, usually can quickly clean up the traces.

- Q: What are the bags and bags?

- According to the material classification as follows: laser aluminum film, re paper materials, laser transfer paper materials, paper composite materials, aluminum composite materials, plastic composite materials, fabric composite materials.

- Q: How much is the 1 wire in the food packing bag printing industry?

- 1 wire =0.01 mm, refers to the thickness of the bag units!Custom food packaging bags, I recommend to have experience in custom food packaging bag manufacturers, because it can reduce the cost and time for many of you, can give you a lot of packaging design and customized recommendations.

- Q: The shelf life of the package usually takes several forms

- Food soft packing materials mainly include polyethylene, polypropylene, polyester, polyamide and other polymer materials. These packing materials show great differences because of their molecular structure, forming process and additives. Therefore, for food manufacturers, choose a suitable packaging for their products is particularly important, otherwise there will be food safety issues.

- Q: What material is the surface of the packing bag such as instant noodles, pickled mustard tuber, small bread and so on? Why should we add this layer?

- First, it is easy to heat seal, otherwise only aluminum foil can not be sealed;Two, high barrier plastic film preservation effect is also very good, can increase its number of layers, reduce aluminum foil thickness, thereby reducing costs

- Q: What is the difference between LDPE and PE-LD in a package?

- LDPE is a low density polyethylene, environmental protection bag production is one of the raw materials, commonly known as low material, another raw material of HDPE is also called high pressure materials, packaging film, the two materials are mixed according to a certain proportion and then blowing, printing, cutting, packing bag made of,PE-LD is a common environmental protection mark printed on top of the packing bag, which indicates that the manufacturer is using an environmentally-friendly plastic bag.

- Q: Antistatic packaging bag with chip

- Black bag production with carbon black, which has a conductive performance, can be generated by friction when the chip electrostatic conductive bag release, however, strictly speaking, conductive black bag, only release the function of static, anti-static must be placed in the box or the box, in order to play the effect.

- Q: Printing solvent for food packing bag

- Determine the amount of water in the solvent by means of the principle of a different dissolution effect. Take the most transparent glass cylinder tube with 100ml toluene solution, take a small amount of analyte ester solvent such as toluene, evenly pour. When you just pour in toluene, carefully observe whether there is turbidity (milk white) phenomenon. If there is this phenomenon, the water content of the solvent is seriously exceeded, and the experience shows that when the moisture content exceeds 0.5%, the phenomenon is obvious. The water content test of benzene solvent can be carried out by extracting solvent from the long glass tube to observe whether there is delamination.

Send your message to us

Bottom Gusset Zipper Closer Kraft Paper Laminated Bags

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 100000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords