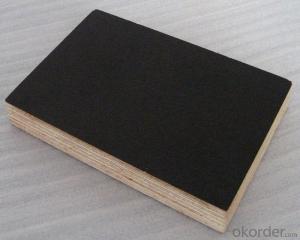

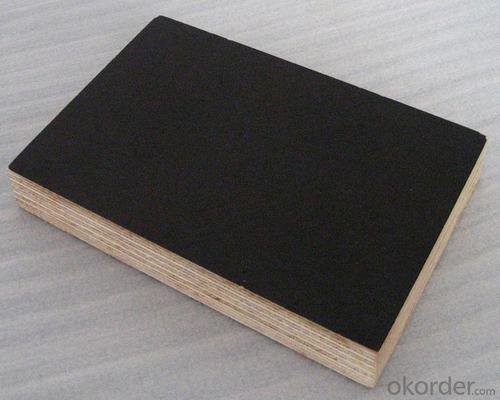

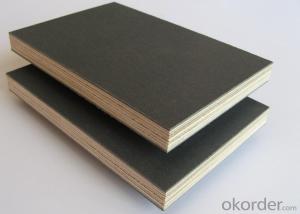

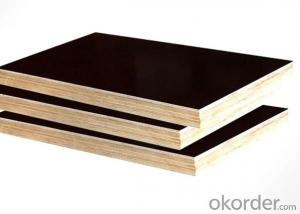

Weight Plywood 3/4 Black Film Faced Plywood Brown Marine Plywood

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 55 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description:

Film Faced Plywood are widely used in construction repeatly.

Characters:

Light, easy to install and disassemble; be used recyclely, waterproof.

Products Details:

Detailed Specification:

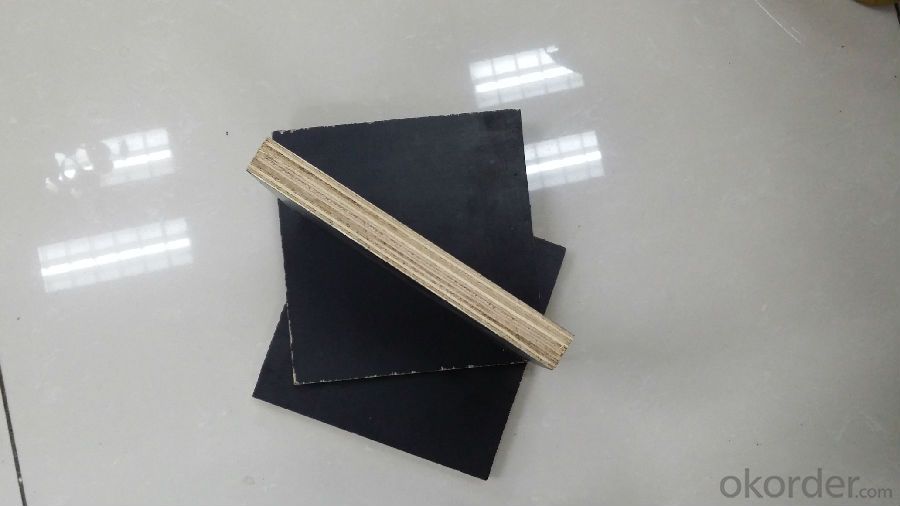

Product name: Black Film Faced Plywood

Size:1220x2440mm,1250x2500mm

Hot press: two times hot press

Thickness:9mm,12mm,15mm,18mm,20mm,21mm,25mm

Tolerance: +/-0.5mm

Core:Poplar,Eucalyptus,hardwood,combi

Film:black with/without logo

Glue:MR,WBP(melamine),WBP(phenolic)

Grade:First class

Moisture:below 14%

Usage:outdoor,concrete forms,formwork,shuttering,construction,etc

Package:Inter packing: 0.20mm plastic bag

Outer packing: pallets are covered with thin plywood or carton and then 4*6 steel straps for strength.

Conveyance:

20’GP:8 pallets/23m³

40’GP:16 pallets/45m³

40’HQ:18 pallets/57m³

Delivery time:

Within 15 days on receipt of deposit or original L/C

Min Order:1X40’FCL

Payment:L/C at sight, T/T(30%deposit)

Supply ability:5000 cubic meters/month

Main market: Middle east,Africa,UAE,Qatar,Oman,Russian,etc

FAQ:

Q1.How many times it can be used?

A1: It mainly depends on hotpress times, quality of raw materials and type of Glue. Normally, Melamine glue poplar core two times hot press film faced plywood can be used about 5-8times.

- Q: The difference between the multilayer board and the plywood is as follows

- Commonly used plywood, plywood and other multi-layer board. Multilayer boards can improve wood utilization and are a major way to save wood

- Q: What is the composition of the plywood?

- Glue plywood usually refers to the plywood or multi-layer board, that is, with the same thickness of two or more layers of veneer plus glue from high temperature suppression.

- Q: Four levels: Principal, First, Second, Third. Commonly used for one, two, three and so on

- Quality grade for the premium, one, two, three a total of four, the indicator is similar to the MDF, but the intensity is much higher than the MDF

- Q: Plywood can improve timber utilization and is a major way to save wood.

- Solid wood furniture with pure solid wood furniture and imitation wood furniture.

- Q: According to the different composition of the glue, for the construction of plywood with the following types of glue

- E0 is the highest environmental rating. E1 grade glue to do the plywood can be used directly for the interior.

- Q: Multilayer board and plywood difference

- A group of boards are usually made of mutually adjacent panels in the direction of the adjacent layers.

- Q: Wood board, plywood, MDF What is the difference

- Blockboard thickness specifications for the 16,19,22,25 mm quality grade is divided into one, two, three three levels

- Q: The Decorative veneer veneer plywood grade classification

- for example,such as some manufacturers logo level "AAA", which is corporate behavior.

- Q: What are the defects in plywood material?

- Fissure check The short separation of the panel fiber usually does not start from the side of the board, not all extending through the thickness of the veneer.

- Q: Solid wood and plywood which is better?

- in addition, also need to consider its ground load capacity and use In the geothermal thermal conductivity; and the general splint or plywood in this consideration is not much.

Send your message to us

Weight Plywood 3/4 Black Film Faced Plywood Brown Marine Plywood

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 55 m³

- Supply Capability:

- 5000 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords