Black Fiberglass Mesh for External and Internal Plaster Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

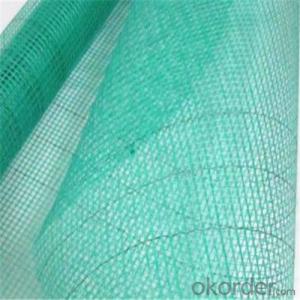

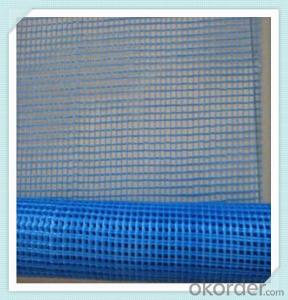

Quick Details of Glass Fiber Mesh, .External and Internal Plaster Reinforcement

Specifications of Glass Fiber Mesh, .External and Internal Plaster Reinforcement

Glass Fiber Mesh, .External and Internal Plaster Reinforcement Place of Origin: China (Mainland)

Glass Fiber Mesh, .External and Internal Plaster ReinforcementBrand Name: CMAX

Glass Fiber Mesh, .External and Internal Plaster Reinforcement Application: Wall Materials

Glass Fiber Mesh, .External and Internal Plaster Reinforcement Width: 1M-2M

Glass Fiber Mesh, .External and Internal Plaster Reinforcement Size: 5*5/ INCH

Glass Fiber Mesh, .External and Internal Plaster Reinforcement Weight: 40gsm to 200gsm

Glass Fiber Mesh, .External and Internal Plaster Reinforcement Weave Type: Plain Woven

Glass Fiber Mesh, .External and Internal Plaster Reinforcement Yarn Type: C-Glass

Glass Fiber Mesh, .External and Internal Plaster Reinforcement Alkali Content: Medium

Glass Fiber Mesh, .External and Internal Plaster Reinforcement Standing Temperature: 500℃

Product information of Glass Fiber Mesh, .External and Internal Plaster Reinforcement

Name: Glass Fiber Mesh, .External and Internal Plaster Reinforcement

Use best fiberglass yarn and best glue

Clear and beautiful Glass Fiber Mesh, .External and Internal Plaster Reinforcement

High strength Glass Fiber Mesh, .External and Internal Plaster Reinforcement

30 years experience of manufacturing Glass Fiber Mesh, .External and Internal Plaster Reinforcement

Excellent Priced Glass Fiber Mesh, .External and Internal Plaster Reinforcement

FAQ of Glass Fiber Mesh, .External and Internal Plaster Reinforcement

Q: What is Glass Fiber Mesh, .External and Internal Plaster Reinforcement?

Coated Alkali-resistant Glass Fiber Mesh, .External and Internal Plaster Reinforcement is based on C-glass or E-glass woven cloth and treated by alkali-resistance copolymer resin on the surface. The woven cloth is made of fiberglass yarn or roving by means of leno or plain weave. The diameter of elementary fiberglass varies between 9 and 15 micron.

Q: What is the specification of Glass Fiber Mesh, .External and Internal Plaster Reinforcement?

Weight: 45-600g Width: 0.2M--2M

Length: 20m, 50m, 100m

Q: What is the application of Glass Fiber Mesh, .External and Internal Plaster Reinforcement?

External thermo insulating composite System (ETICS) & External insulating finish system (EIFS)

External and internal plaster reinforcement

Electrical heating mats

Marble slab reinforcement / Mosaic carrier

Asphalt reinforcement (roof water-proof)

Reinforced lightweight construction boards

Q: What is the storage of Glass Fiber Mesh, .External and Internal Plaster Reinforcement?

Store rolls in a cool, dry location

Store away from the direct contact with ground or concrete

Store out of direct sunlight

Protect rolls from weather and other damage

Q: What is the guarantee period of Glass Fiber Mesh, .External and Internal Plaster Reinforcement?

Four years under normal weather conditions and use .

Q: What is the package of Glass Fiber Mesh, .External and Internal Plaster Reinforcement?

Package: rolls are packed into cartons or pallets.

Packing volumes: 30000m2/40HQ.

Q: Wow long about the production periods of Glass Fiber Mesh, .External and Internal Plaster Reinforcement?

Production periods: 30days for 1X40HQ.

- Q: How to DIY the setting adhesive of glass fiber gridding cloth?

- With glass fiber woven fabric as base material, gridding cloth is dipped in and coated with highly resistant polymer emulsion, thus featured by good alkali resistance, flexibility and high tensile resistance in the bidirection of warp and weft. It is widely used for thermal insulation, water proofing and crack resistance of internal and external walls of buildings. The glass fiber gridding cloth mainly adopts alkali glass fiber yarn (with silicate, stability as main components) and made by high-temperature heat setting such as anti alkali liquid and strengthening agent of the special organization structure - lace stitch.

- Q: How to use gridding cloth tape, namely glass fiber self adhesive tape?

- Use it with the case sealing tape.

- Q: During the civil engineering, lintel and the red?brick are to prevent cracking, and whether it is good to use the mesh or the wire entanglement.

- the structure like this should be brick structure, I suggest using the steel mesh, and mesh should be wrapped the corner or used on the external wall

- Q: What is the performance of wall mesh?

- Wall mesh is also known as glass fiber wall mesh, which is made from C-fiberglass yarn and E-fiberglass yarn on the basis of glass fiber mesh, and is a new type of alkali resistant product by coating acrylic?acid copolymer and drying. Wall mesh is characterized by structural stability, high strength, good alkali resistance, anticorrosion and cracking, reinforcement is the best, and the construction is simple and easy to operate. Wall Mesh is mainly used in cement, gypsum, walls, buildings and other structures for the reinforcement and cracking of inside and outside surface, which is a new type of construction materials for external wall thermal insulation projects.

- Q: What's the use of gridding cloth pasted on the wall?

- With middle-alkali or alkali-free glass fiber gridding cloth as base material, alkali resistant wall glass fiber gridding cloth is made by coating modified acrylate copolymer adhesive solution. It is featured by lightweight, high strength, resistance to temperature, alkali, water, corrosion and crazing and size stability. It can effectively avoid the tension contraction of plaster layer surface and cracks caused by external force. Light gridding cloth is often used for wall renovation and interior wall insulation.

- Q: Fiberglass mesh reinforced waterproof roll is via the texture of the tire to distinguish the waterproof quality. General polyester tire is better than fiberglass tire in quality.

- PE polyethylene film, varieties The coiled material uses two sub tread mark?number: glass fiber felt or polyester felt. The nominal weight of coiled material... What kind of SBS shoule be taken?

- Q: Who has a clear understanding of the specifications of the thermal insulation Mesh?

- The main distinction between the external wall thermal insulation Mesh and the interior wall Mesh is the different raw material of them. The external walls Mesh are generally with the raw material of alkali or alkali-free mesh, and then after multideck coating , it becomes an alkali resistance Mesh. This products are with a very good stability and a strong tensil strength which is easy for the construction. The cement and building walls can be very effective to enhance the tension strength. The mesh of the interior wall is with the glass fiber as the main raw material, but also through various process. This Mesh of the interial wall is an ideal material for the grc wallboard.

- Q: Powder modified asphalt polyester blanket is a lower quality waterproofing material made of powder instead of polymer. Glass fiber gridding cloth reinforced waterproof coiled material uses waterproof coiled material as base

- Glass fiber gridding cloth reinforced waterproof coiled material Waterproof coiled material Difference: the quality of polyester reinforcement is higher than fiberglass reinforcement.

- Q: How to use resin and good glass fiber gridding cloth?

- Resin has better liquidity, so the dipping time is longer; if possible, the gridding cloth should not be dense. Using coupling agent before dipping may have a better boding effect.

- Q: Joints of different materials on wall need to be pasted with steel mesh or fiberglass mesh, and the parallel position with beam column must be pasted, then what about the unparallel position?

- The junctions of different materials on walls needs to be paved with steel mesh or fiberglass mesh before plastering. It also needs to be pasted. The unparallel position should be the internal corners. The width of mesh should assure 200mm of both sides.

Send your message to us

Black Fiberglass Mesh for External and Internal Plaster Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords