Best Quality Aluminium Perforated Grid Ceiling China Supplier

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | Place of Origin: | Brand Name: | |||

| Model Number: | Function: | Feature: | |||

| Ceiling Tile Shape: | Ceiling Tile Type: | Surface Treatment: | |||

| Metal Ceiling Material: | Key word: | Specification: | |||

| Height: | Thickness: | Perforated diameter: | |||

| Color: | MOQ: | Delivery time: | |||

| Packing: | Certificate: |

1) Our clip in aluminum ceiling:

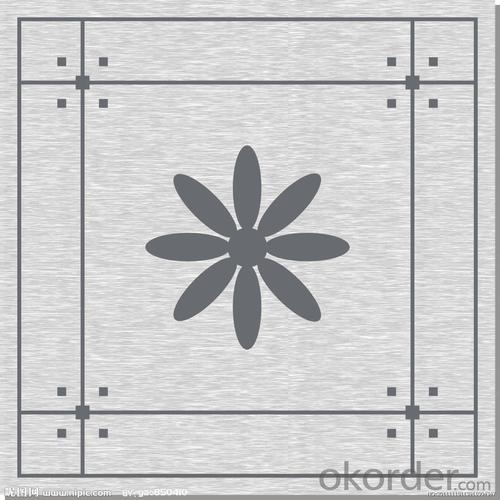

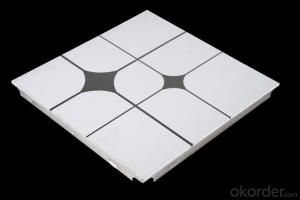

Clip in square ceiling, widest applicable among all type of ceiling with outstanding advantages. Plain or pattern can be selected according to the actual requirement. Clip in system which is concealed, steady structure, flat surface, could be both used as ceiling and wall panel.

2) Specifications:

| Specification | Thickness | Height | Legend |

| 300×300mm | 0.4-1.0mm | 19mm(short edge) 25mm(High edge) |  |

| 300×450mm | |||

| 300×600mm | |||

| 300×1200mm | |||

| 400×400mm | 0.5-1.2mm | ||

| 500×500mm | |||

| 600×600mm | |||

| 600×1200mm | |||

| Base materials | Aluminum alloy, the grade of aluminum alloy can be selected according to the actual requirements; Besides, galvanized iron and stainless steel material is also available | ||

| Surface treatment | Powder coated(ordinary powder, Polyester powder), Paint coated, Film coated | ||

| Type of Surface | Plain plate or perforated plate is selected according to the actual requirements | ||

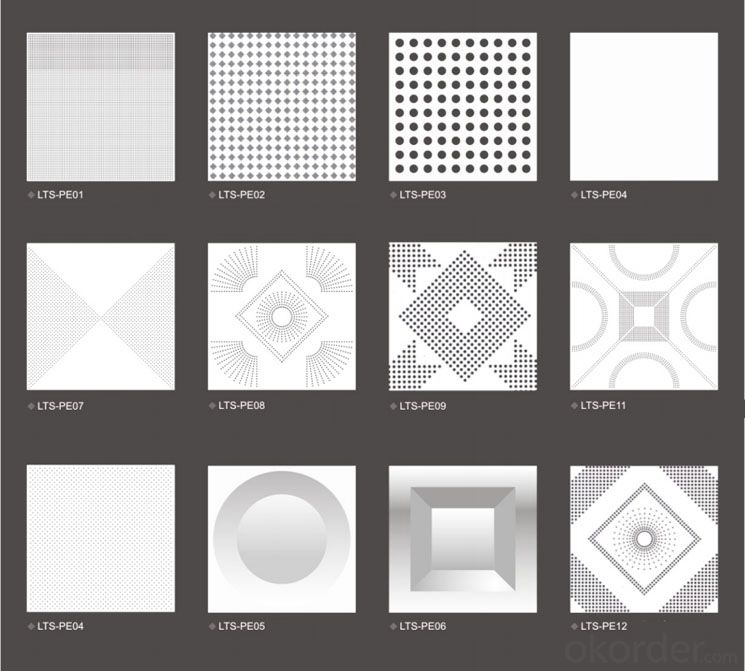

3) perforated pattern:

Perforation is a kind of processing technology for metal ceiling.Ceiling design beautiful patterns according to the arrangement of perforated holes with powerful sound absorbing and isolating effect. Rators possesses over 40 kinds of fixed perforated types, and could be customized according to client's requirements on patterns, sound absorbing to meet the actual situation.

4)Our Packing:

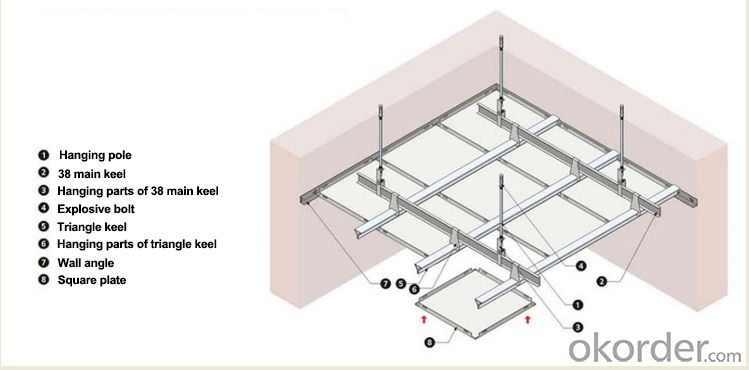

5)Installation Method:

The upper main keel and lower triangle keel are tightly connected with "cross" structure,therefore,it can assure the levelness of whole suspended system with more solid structure.

6)Sample Project:

7)Application:

mainly used in project for big area with soundproof requirements, such as hotels,stores,office building, hospitals,railway stations,metro stations and so on.

8)Certificate:

ISO9001:2008, BV,TUV, Product Quality Certificate.

9)Factory Tour:

Installaiton & Accessories.

*Clip-In Panels are constructed of recycled aluminum

*Springs and clips are constructed of high performance steel

*Clip-In Panels integrate into and conceal 15/16” face HD/ID suspension grid

*Clip-In Panels for use in interior application

*Square edge design

*Standard sizes of 24” x 24”, 24” x 48” or custom size

*Clip-In Panels available in solid or perforated designs

*Clip-in placement allows for downward accessibility without special tools

*Easily incorporates air, fire, audio and other services

*Panels contain no organic compounds that support mold or microbial growth

*Factory applied, no-VOC powder coated paints and laminated finishes

- Q: What sound insulation is good? What is the effect of aluminum foam?

- Home listening room decoration should take measures including noise and sound absorption, the object is invisible sound, certainly have a considerable difficulty. The actual process requires some skills, only for sound protection measures, because the environment and the playback volume of the difference is very different. Generally to be the noise measures to be divided into three: First, the doors and windows for sound treatment; Second, the room 6 surface noise treatment; Third, the construction of "room room."

- Q: How to sub-aluminum buckle plate is good or bad?

- Look at the keel: keel is good or bad is a lot of consumers ignore the problem, the keel material is generally divided into aluminum, iron and no fingerprint steel. Aluminum keel will not rust, but because the cost is relatively high sales so very little. Iron keel is easy to rust, although the keel section hidden in the back of the ceiling generally do not see, but the rust scattered on the ceiling on the ceiling is not good, over time will affect the stability of the ceiling. No fingerprint steel keel relative to the iron keel it is not so easy to rust, is currently the most commonly used home improvement tooling sales. I sincerely hope that consumers can buy their own ideal integrated ceiling products.

- Q: The top of the kitchen ceiling of the ceiling of the ceiling

- Fine work, take the first piece of plastic plate with a plastic sucker (or tape) to take, be careful to get the buckle plate is not easy to install.

- Q: Mirror aluminum ceiling for the kitchen is good, choose which brand of high cost, it will absorb fumes?

- Yes, the American standard is not bad Oh.

- Q: Exhibition hall ceiling aluminum grid 3d is how to do

- In fact, with the other curtain wall concealed works the same practice, concealed works will be closed after the invisible place to the supervision and acceptance, and confirmed on the acceptance can be, the glass curtain wall is basically covered by the part of the hidden layer of the hidden , The information around the electronic dog has.

- Q: What is the effect of the material on the quality of the product?

- It is certainly the quality of primary aluminum and aluminum recovery is certainly not the same as the latter part of the processing method or anodic oxidation can affect the impact

- Q: Aluminum buckle board a side of the edge of how fixed

- There are a lot of ways to fix a long way to achieve a strong, but not good to do so unless the nails, but in the tiles on the job so it is difficult to do Other methods are; generally more solid I used almost can reach 2 years, After all the adhesive tape with a transparent tape so that all the time can be long. Other uses are simple and fast and the use of up to a year, there are direct tape with glass glue nail rubber, etc.

- Q: Want to open a small aluminum buckle board processing plant about how much money

- You need one or two workers (relatives also line) forming sheet, pre-need to print brochures and banners, distributed in the market publicity. You also need a safe and convenient molding equipment, a minute to produce 60 pieces of sheet; equipment to be safe, will not crush the staff of the palm. Guests need to buckle when you can provide timely.

- Q: Hall ceiling is what material is better aluminum card board, gypsum board, or wood version?

- Remember not to look at the thickness, do not look at the material, like the best foreign music Le Long, the best domestic times and other brands Ming Li Ming, ordinary home improvement thickness of 0.5,0.6, rarely to 0.8mm, The reason is that people use the aluminum alloy material is good, not very thick enough, and then there will be a lot of home strap buckle span, there is no need to use so thick.

- Q: How can I install an aluminum cords with a ceiling?

- The correct construction sequence is like that.

Send your message to us

Best Quality Aluminium Perforated Grid Ceiling China Supplier

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords