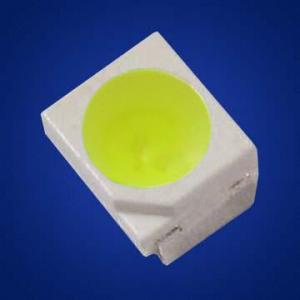

Best Offer SMD LED Diodes

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

best offer SMD LED

ISO9000&ISO14000 Certification

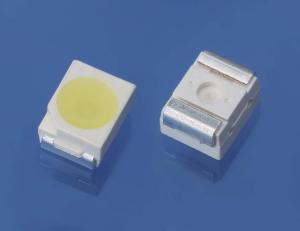

Easy assembly to all SMT items.

best offer, long life

Production details:

1. IV-Typ:200mcd 2.IV-Max:300mcd 3.Vf-Min:1.7V 4.Vf-Max:2.5V 5. If:20mA

2. wavelength:600-610nm

And we can also make a specific design as per your brightness requirement.

SMD Features:

1. 5050, 3528, 3020 series are available from our company.

2. Various colors are available:

Colors available | |

Warm White2500~5000K | Net White5000~7500K |

Cold White7500~13000K | Red620~635nm |

Yellow585~590nm | Green520~530nm |

Blue465~475nm | Amber600~610nm |

RGB620~630nm520~530nm465~475nm | |

3. We have a QC control for every detailed procedure, and the following ALT Reliability test is one for an example:

Reliability testing profile:

NO | Testing items | Testing profile | Time | Defect rate | |||

1 | Burning test at room temperature | Ta=25 If=20mA | 1000hrs | 0/22 | |||

2 | Burning test at High temperature /humidity condition | Ta=85 RH=85% If=10mA | 500hrs | 0/22 | |||

3 | Burning test at low temperature | Ta=-40 If=20mA | 1000hrs | 0/22 | |||

4 | High temperature /humidity storage test | Ta=85 RH=85% | 1000hrs | 0/22 | |||

5 | Low temperature storage test | Ta=-40 | 1000hrs | 0/22 | |||

6 | HOT-COLD CYCLE TEST | -40/100,10mins. | 200Cycles | 0/22 | |||

7 | Thermal shock | -40/100, 10mins. | 200Cycles | 0/22 | |||

Standards for the defect items | Profile | Standards | |||||

|

| Min. volume | Max volume | ||||

VF | If=20mA | ---- | ---USL×1.2 | ||||

IR | Vr=5V | ---- | ---USL×2.0 | ||||

IV | If=20mA | LSL×0.7 | --- | ||||

USL:Max volume LSL:Min volume | |||||||

Packaging & Shipping

Packing:

Standard packing inside, cartons outside

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

Air freight | 3-10 business days |

By Sea | 30-40 business days |

1. 3-5 business days for Sample Orders; 7-30 business days for Bulk Orders for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

Application case:

LED Ribbon:DIP3mm series, SMD3528 series, SMD5050 series...

LED Tube Lamp:T5 series, T8 series T10 series...

LED Down Lights:6Watt, 12Watt, 14Watt, 16Watt, 18Watt...

LED Panel Lights:300*300, 300*600, 600*600, 600*1200...

LED Flood Lamp:10Watt series, 30Watt series, 50Watt series, 80Watt series...

LED Industrial Lamp:50Watt series, 80Watt series, 100Watt series...

LED Road Lamp:100Watt series, 200Watt series...

LED Bulb Lamp:MR16 series, GU10 series, E27 series...

About Us

We have been providing the internatinal and domestic market with quality electronic components . We offer a wide range of electronic components,including absolute and hard to find parts. We bring the proven reliability of an experienced provider and the skills of a seasoned team of sales professionals together to provide accurate,cost-effective and timely solutions to a growing base of global customers. We have stringent quality controls in place to ensure that you receive only top-quality new and unused parts for your production.

We can provide:

High quality of Components

Competitive prices with convenient payment terms

Fast delivery times Long time warranty

- Q: Production of a number of substrates, the use of SMD LED lights, red lights and green lights are not bad, blue lights appear mass dark, do not know why? Is the LED blue light material easy to use dark?

- If you choose the brightness of blue light in the light of the relatively high, so when debugging the white balance (by changing the resistance to change the current, and then change the RGB brightness LED lamp), it is difficult to transfer to the pure white. Therefore, when selecting the lamp, the blue light is generally not bright.

- Q: What is the difference between SMT LED packaging with silicone and epoxy resin transparent package? What is the market situation of these two types of packaging?

- The main difference is the encapsulation method. The liquid silicone is mainly encapsulated and encapsulated, while the gum cake is solid and adopts a transfer molding package. Of course, there is a fundamental difference between the material, silica gel can be used for white light high-power LED, suitable for lighting. The epoxy can only be used in low-power monochrome LED, suitable for display, backlight, induction and other components.

- Q: What should I notice when I want to solder 1206 LED patch type luminous tube on fine copper wire?,

- The peak reflow temperature: 260 degrees or below this temperature. (surface temperature) 2 temperature over 210 DEG C required time: 30 seconds or less than this time. 3 reflow times: no more than two times. 4 after reflow, LED needs to be cooled to room temperature before contact with colloid.

- Q: What is patch SMD-LED?

- Semiconductor wafers consist of two parts, one is P type semiconductor, in which the hole dominates, and the other end is N type semiconductor, which is mainly electronic here. But when the two semiconductors are connected, they form a P-N junction between them. When the current passes through the wire acting on the chip, the electrons are pushed into the P region. In the P region, electrons combine with the hole and then emit energy in the form of photons, which is the principle of LED luminescence. The wavelength of light, that is, the color of light, is determined by the material that forms the P-N junction.

- Q: LED patches have several ways of welding. Which ones can be reflow? What can be done by eutectic welding? Is the welding of viscose and lens material is required?

- SMD patch products basically can be used in reflow soldering, especially a little note here that the eutectic welding is the connection between the chip and the substrate support or specifically, is the bottom of the chip after completion of production of coating material and a layer of Sikkim alloy, and then set up a heating zone in solid crystal machine package in time and a temperature of about 300 degrees, the realization process of the chip at the bottom of the Sikkim alloy melt and silver plated layer connection bracket, and a clear distinction between reflow.

- Q: Does anyone know what the current rating of a white high brightness LED patch is? Where can I find out?

- The high power 1W is 350MA, and 3W is 700MA. They are all fixed and can be found everywhere.

- Q: Patch LED features

- The principle of luminescence is that of cold luminescence, not by heating or discharging light, so the component life is about 50~100 times longer than that of tungsten filament bulb, and about one hundred thousand hours.

- Q: LED package and LED SMD LED lamp, what is the difference? Will the release agent be used in that part?

- Packaging is for TOP series LED, that is, the type of plastic molding. The patch is based on the PCB circuit board for molding. Mold release agent is used in molding.

- Q: The ten patch LED lights are connected in parallel. The rated power is 5 watts. How much voltage do you need?

- The ten patch LED lamps are connected in parallel with rated power of 5 watts and voltage 3.3V.

- Q: Such as title, please have welding patch LED lamp experience expert guidance, do not search from the Internet to the theoretical knowledge, thank you!

- First of all, welding LED and other electronic products with line electrostatic ring, to prevent static light.When welding the patch LED lamp, first add the tin on the pad of the lamp board, then clamp the LED patch lamp with tweezers. Then, the soldering iron will melt the tin of the solder plate of your lamp board, and then push the LED lamp onto the pad with tweezers. The whole welding process should not exceed 5 seconds, otherwise it will burn the lamp easily.

Send your message to us

Best Offer SMD LED Diodes

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords