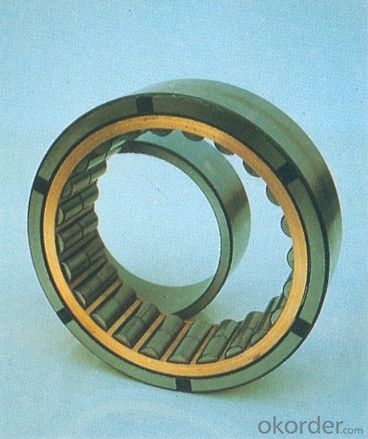

Bearings four row cylindrical roller FC2234120

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Four row cylindrical roller bearings

Four row cylindrical roller bearing is usually use in rolling mill’s work roll or back-up roll. It mainly take much radial load, which is extensively used on the work roll of wire rod mill, section mill and bloomer mill , as well as the back-up roll of dressing machine, cold rolling mill and hot rolling mill.There are three kinds of structures: FC, FCD, FCDP. There are three grades for tolerance : 0 , 6 , 5.

FC: double outer ring, single inner ring, inner ring without rid;

FCD: double outer ring, double inner ring, inner ring without rid;

FCDP:double outer ring, double inner ring, inner ring without rid

★ Product Features of bearings:

The rollers of the cylindrical roller bearing are usually guided by two flanges of a ring.

Because this assembly part composed of cage, roller and guide ring can be separated from

another ring, the cylindrical roller bearing belongs to separable bearing. This type of bearing

can be easily mounted and dismounted. Its advantages are obvious especially when there is

interference fits between the inner, outer ring and the axis, housing.

This bearing is usually subjected to radial load, only the single-row bearing with inner& outer

rings flanges can bear small steady axial load or great intermittent axial load. It has a high

requirement on the processing of the fitting parts such as axis and housing bore, etc.

★Product Application of bearings:

Cylindrical roller bearings are mainly used for:

- Iron and steel metallurgical industry

- medium and large motor

- generator

- combustion engines

- gas tuibine

- machine tool spindle

- speed reducer

- loading and unloading machinery and all kinds of industrial machinery

Four Cylindrical Roller Bearings Catalugue

- Q: NSK cylindrical roller bearings EW/EM series of differences and characteristics

- M international is called brass retainerThis can be a question, just ask, for reference only

- Q: How much is the axial force of double row cylindrical roller bearings? How is it calculated?

- The cylindrical roller bearings have ribs can withstand certain axial force, the axial force for cylindrical but still belongs to the non normal stress, can cause early failure of the bearing, it is generally not given the axial bearing capacity, no formula

- Q: How are the twin row cylindrical roller bearings classified?

- Double row cylindrical roller bearings have cylindrical inner bore and conical inner bore (bearing rear code plus K) two structures. This kind of bearing has the advantages of compact structure, large rigidity, large bearing capacity and little deformation after load. It is especially suitable for spindle support of machine tools. The conical inner hole can also play the role of micro adjustment of the clearance, and can simplify the positioning device structure, and is convenient for installation and disassembly.

- Q: what does that mean? Please enlighten master, thank you.

- Hello, E on behalf of hanging behind the cage (black) steel cage; EM stands for copper holder.

- Q: Attention problems of cylindrical roller bearings

- 1. The installation of bearings must be carried out in a dry, clean environment. Before installation, the machined surface of the shaft and shell, the shoulder end, the groove and the joint surface shall be carefully inspected. All mating surfaces must be carefully cleaned and removed, and the cast surface must be clean. 2, before the installation of bearings, should be cleaned with gasoline or kerosene, dry after use, and ensure good lubrication, bearings generally grease lubrication, oil lubrication can also be used. Grease lubrication, grease, anti rust, extreme pressure and other excellent greases should be used. Grease filling capacity for bearings and bearing box volume of 30%-60%, should not be too much. Double row tapered roller bearing and water pump shaft bearing with sealing structure have been filled with grease, which can be used directly by users and can not be cleaned again. 3, bearing installation, must be applied equally in the circumference of ferrule end face pressure to press into the ring, and may not directly tap bearing end face to the top tool, so as not to damage the bearing. Small amount of interference in the case, at room temperature can be used to suppress sleeve bearing ring face, beating with a hammer sleeve, the sleeve will be pressed into the ring balance. If installed in large quantities, use hydraulic press. When pressing, the outer end surface of the outer ring and the outer shoulder of the shell face shall be ensured, and the inner ring end face is tightly pressed with the shoulder end of the shaft platform, and no gap is allowed.

- Q: Why cylindrical roller bearings can not bear axial load?.

- Bearing bearing axial force or radial force is determined by the structure of the bearing, thrust ball bearings are also called plane bearings, which are mainly used to bear axial force; cylindrical roller bearings can bear radial forces and are not suitable to bear axial force.

- Q: Why does cylindrical roller bearings fail abnormally?

- Generally, the causes of abnormal failure of cylindrical roller bearings are as follows:1, cylindrical roller bearing manufacturing accuracy is poor, one end of the bearings with loose, and travel source is larger, bearing frame rigidity is poor. Or the bottom of the bearing seat is uneven.2, cylindrical roller bearings axis misalignment (misalignment) axis and the housing of the shoulder to the surface is not vertical, shell installation, bearing two or more holes, different axis.

- Q: How should I find the concentricity of cylindrical roller bearings after installation?

- Any form of assembly, adjustment center is a very troublesome thing, but also in the measuring installation is not very complete, the usual method is to in the base below (or below) thin copper with different thickness, until you feel better, but each installation to re adjust. So, in the machining process, try to use special fixtures and parts drawing in tol and other measures to avoid such a remedy".

- Q: Rolling bearing face to face or back to back on the use of cylindrical roller bearing pairs, the speed limit will be reduced? Please, thank you!

- Rolling bearing face to face or back to back, the speed limit will be reduced? Yes, especially in order to obtain a large preload or a large gap of the matching. Cylindrical roller bearings in pairs, the limit speed will be reduced? Cylindrical roller bearings do not exist in pairs, one said that you can use the same internal and external diameter of double row, four column cylindrical bearings, the same internal and external diameter of double row, four column bearings, compared to single row cylindrical bearings limit speed will be reduced

- Q: Why should the main shaft be coupled with double row cylindrical roller bearings?

- Separable, easy to install and disassemble, mainly used in lathe, milling machine, machining center and other high-precision machine tool spindle. Hope to be of help to you.

Send your message to us

Bearings four row cylindrical roller FC2234120

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 pc

- Supply Capability:

- 5000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords