Bearings four row cylindrical roller FC202870

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Four row cylindrical roller bearings

Four row cylindrical roller bearing is usually use in rolling mill’s work roll or back-up roll. It mainly take much radial load, which is extensively used on the work roll of wire rod mill, section mill and bloomer mill , as well as the back-up roll of dressing machine, cold rolling mill and hot rolling mill.There are three kinds of structures: FC, FCD, FCDP. There are three grades for tolerance : 0 , 6 , 5.

FC: double outer ring, single inner ring, inner ring without rid;

FCD: double outer ring, double inner ring, inner ring without rid;

FCDP:double outer ring, double inner ring, inner ring without rid

★ Product Features:

The rollers of the cylindrical roller bearing are usually guided by two flanges of a ring.

Because this assembly part composed of cage, roller and guide ring can be separated from

another ring, the cylindrical roller bearing belongs to separable bearing. This type of bearing

can be easily mounted and dismounted. Its advantages are obvious especially when there is

interference fits between the inner, outer ring and the axis, housing.

This bearing is usually subjected to radial load, only the single-row bearing with inner& outer

rings flanges can bear small steady axial load or great intermittent axial load. It has a high

requirement on the processing of the fitting parts such as axis and housing bore, etc.

★Product Application:

Cylindrical roller bearings are mainly used for:

- Iron and steel metallurgical industry

- medium and large motor

- generator

- combustion engines

- gas tuibine

- machine tool spindle

- speed reducer

- loading and unloading machinery and all kinds of industrial machinery

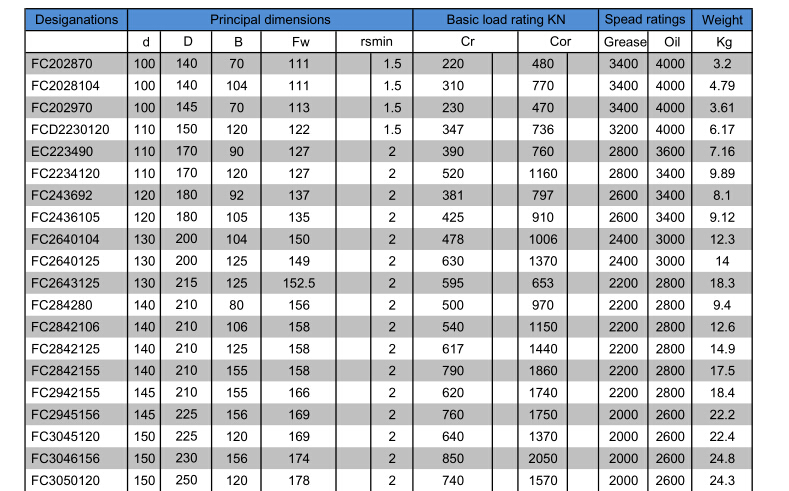

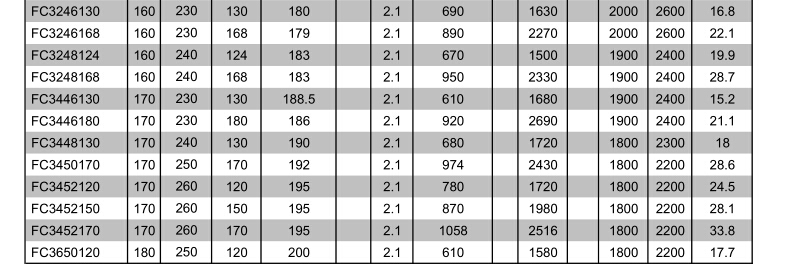

Four Cylindrical Roller Bearings Catalugue

- Q: Full use cylindrical roller bearings, uses and advantages?

- Full cylindrical roller bearings are designed to withstand heavy loads. At the same width, this kind of bearing, compared with the traditional belt cage bearing, has a very high carrying capacity, radial cross-section is small, it can save space, but the speed is relatively low.

- Q: what does that mean? Please enlighten master, thank you.

- You should say that the Japanese NSK bearings? NSK, N216, E stands for high load cylindrical roller bearings, N216 EM, which represents high load cylindrical roller bearings, copper alloy solid cage. E, which means strengthening the design, so the load capacity of bearings is better than without E.

- Q: Attention problems of cylindrical roller bearings

- High temperatures often indicate that cylindrical roller bearings are in exceptional condition. High temperature is also harmful to bearing lubricants. Sometimes the bearing is overheated and can be attributed to the lubricant in the bearing. If the bearings are longer than the temperature of 125 degrees, even the transfer will reduce the bearing life. The causes of high temperature bearings include: insufficient lubrication or excessive lubrication, impurities in the bearing raceway, extreme high speed, long term overload operation of bearings, etc..

- Q: Why cylindrical roller bearings can not bear axial load?.

- The thrust bearing retainer plate and two pieces of circular hole of the ball and the ball hole and shaft wear in the park, circular plate, steel ball track between two plate, shaft and the bearing seat of the top plate in the round two sides, in addition to the track groove, it is not binding the radial direction, so it cannot withstand the radial load.The radial bearing by the size of the two steel ring, steel ball size between steel ring, steel ring diameter fixed by a bearing seat, shaft mounted on a small steel ring, binding only in the radial direction and axial direction of the load is not binding, so it cannot withstand the axial diameter.

- Q: Why does cylindrical roller bearings fail abnormally?

- 3, the rigidity of the shaft is poor, too large bending occurs under the load, and the span of the fixed end of the cylindrical roller bearing two is larger. When the temperature rises, the thermal elongation of the shaft causes the bending of the axle static property.4. The assembly surface falls into the hard particle or the dirt, the stress concentrates, to the open bearing pedestal when clamping, the cylindrical roller bearing ring clamp flat.

- Q: What's the difference between imported bearings and imported bearings?

- The 2 kind of bearing retainer material is mostly copper, and the retainer pin is also copperThere is also a steel retainerImported bearings also have copper and steel

- Q: What are the components of cylindrical roller bearings?

- The utility model has the advantages of convenient installation and disassembly, especially when the inner, outer ring and the shaft and the shell are in interference fit. Such bearings are generally only used to bear radial load, only the inner and outer ring with single block bearings can bear less axial load or larger intermittent axial load.

- Q: Cylindrical roller bearings, in the grease after the operation for a short period of time, the grease was thrown out (thrown to the end cap), resulting in roller and raceway between the lack of grease, lubrication poor. Decomposition found that the roller has round circumferential friction marks, but also on the roll, but compared to the roller is very slight. And there are relatively sound bearings, abnormal sound.Is this phenomenon normal? What if it doesn't work? What was the reason? What's the solution? StopThanks for your help!Assuming the grease is no problem, viscosity, consistency, selection is no problem If exclusion is the problem of grease, what other reasons can this be the case? ?

- If the grease is dry, adhesion is not good, some of the high temperature grease stored for a long time will be dry, it will apply to the bearing is easy to get rid of, especially now the winter oil solidification, the lubrication effect is less. It is recommended to use low temperature grease in winter or add some oil to dilute it. The best way is to change the grade of grease. If the inner ring of the bearing can be removed, grease can be filled from it.

- Q: How to calculate the clearance of bearings, such as 23226 double row cylindrical roller bearings

- 1, radial clearance: non preload, bearing radial load, the radial clearance of G for any angle along the radial direction, in the absence of external load relative to the outer ring inner ring from a radial eccentric limit position, move to the opposite limit position of the radial distance arithmetic mean.2, axial clearance: non preload, bearing can withstand axial load in two directions, the axial internal clearance of G: without external load, a ring relative to the other ring, from an axial limit position toward the average axial distance limit position opposite the.

- Q: Why should the main shaft be coupled with double row cylindrical roller bearings?

- Separable, easy to install and disassemble, mainly used in lathe, milling machine, machining center and other high-precision machine tool spindle. Hope to be of help to you.

Send your message to us

Bearings four row cylindrical roller FC202870

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords