Bearings double row cylindrical roller NN3032K

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Double row cylindrical roller bearings

The rollers of the double row cylindrical roller bearing are usually guided by two flanges of a ring.

Because this assembly part composed of cage, roller and guide ring can be separated from another

ring, the cylindrical roller bearing belongs to separable bearing. This type of bearing can be easily

mounted and dismounted. Its advantages are obvious especially when there is interference fits

between the inner, outer ring and the axis, housing.

This bearing is usually subjected to radial load, only the single-row bearing with inner& outer rings

flanges.

- NN double row cylindrical roller bearings

This kind of bearings with inner rid, no outer rid.This assembly part can be separated from another ring, and they have larger radial load capacity than other single row cylindrical roller bearings with the same size, but the axial or housing is free axial displacement, so this kind of bearings can only bear the axial load.

★ Product Features:

The rollers of the cylindrical roller bearing are usually guided by two flanges of a ring.

Because this assembly part composed of cage, roller and guide ring can be separated from

another ring, the cylindrical roller bearing belongs to separable bearing. This type of bearing

can be easily mounted and dismounted. Its advantages are obvious especially when there is

interference fits between the inner, outer ring and the axis, housing.

This bearing is usually subjected to radial load, only the single-row bearing with inner& outer

rings flanges can bear small steady axial load or great intermittent axial load. It has a high

requirement on the processing of the fitting parts such as axis and housing bore, etc.

★Product Application:

Cylindrical roller bearings are mainly used for:

- Iron and steel metallurgical industry

- medium and large motor

- generator

- combustion engines

- gas tuibine

- machine tool spindle

- speed reducer

- loading and unloading machinery and all kinds of industrial machinery

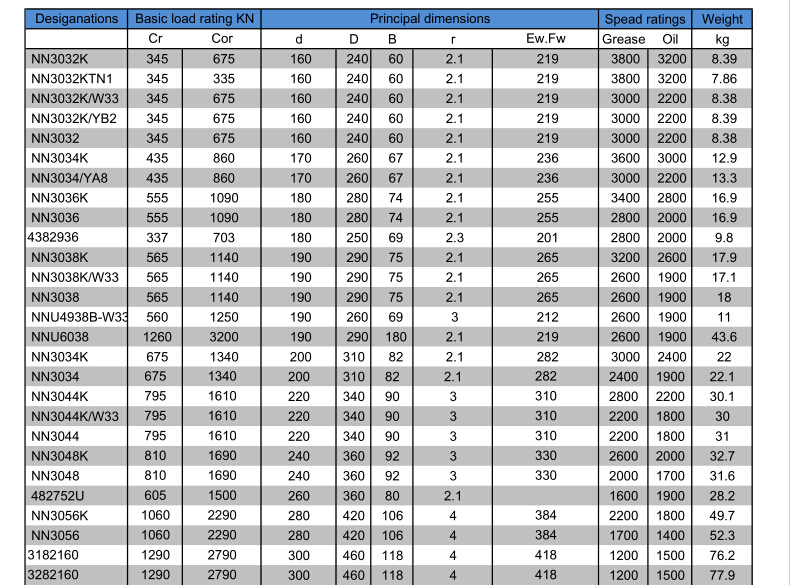

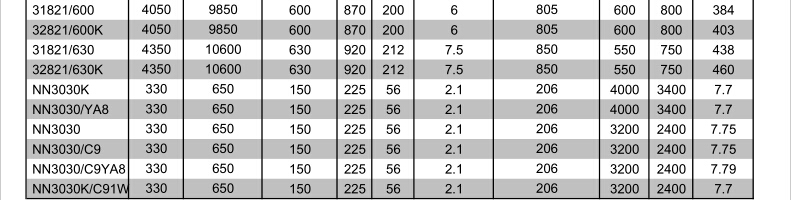

Double Row Cylindrical Roller Bearings Catalogue

- Q: Why are cylindrical roller bearings suitable for traveling support?

- Cylindrical roller bearings without inner sides of the inner ring or outer ring, whose inner and outer rings can be moved relative to the axial direction, so they can be used as free end bearings.

- Q: What is the limit speed and rated dynamic load of NSK full M40-19g cylindrical roller bearings, HTF?

- NSK bearing type suffix solution of NSK bearing type by the basic code, prefix and post code, the basic code bearing series (including type) diameter and contact angle; pre code specific bearing; post code structure shape, bearing size, material, seal, retainer, clearance, heat tolerance processing, lubrication, change and other technical requirements, in addition to the basic code added after bearing code. NSK bearing model prefix F - deep groove ball bearing with flange outer ring (for D less than 10 mm), for example: F605. HR - high load tapered roller bearings, for example: HR30207J. MF - Flanged, outer race, deep groove ball bearings of specified sizes (D less than 10 mm), MF52. MR - deep groove ball bearings of specific size (for D less than 10 mm), for example: MR31. NSK bearing type rear code (1) internal structure A - internal design and standard different bearings. A - angular contact ball bearings with a contact angle of 30 degrees. A5 - angular contact ball bearings with a contact angle of 25 degrees. B - angular contact ball bearings with a contact angle of 40 degrees. C - angular contact ball bearings with a contact angle of 15 degrees. C - tapered roller bearings with a contact angle of 20 degrees.

- Q: What is the maximum rotational speed of a single row full cylindrical roller bearing?

- FAG single row full cylindrical roller bearingsFAG single row full cylindrical roller bearings can bear large radial loads, and can also bear single direction axial load. Axial positioning can be guaranteed by a symmetrical arrangement of similar bearings. NCF, 29V, NCF, 30V series of bearings have two fixed inner ring, the outer ring has a baffle, they can only bear the direction of the outer edge of the fixed axial load. The NJ23VH series bearings can bear the axial load toward the inside of the inner ring, and their rollers are fixed in the outer ring, even if the inner ring is taken away. The two rings are tight fit, easy installation and disassembly.

- Q: cylindrical roller bearings N210 20Deep groove ball bearings 6120, self-aligning ball bearings 1210, cylindrical roller bearings N210 in the same radial force conditions, the life expectancy of the three levels and how to compare? What is the cause of the high and low?

- Summary: the above three kinds of bearings, the service life in accordance with the order from high to low: deep groove ball bearings, self-aligning ball bearings, cylindrical roller bearings.

- Q: Why does cylindrical roller bearings fail abnormally?

- 3, the rigidity of the shaft is poor, too large bending occurs under the load, and the span of the fixed end of the cylindrical roller bearing two is larger. When the temperature rises, the thermal elongation of the shaft causes the bending of the axle static property.4. The assembly surface falls into the hard particle or the dirt, the stress concentrates, to the open bearing pedestal when clamping, the cylindrical roller bearing ring clamp flat.

- Q: What are full cylindrical roller bearings?

- Full capacity roller bearings are divided into double row full load roller, single row full roller, outer spherical roller, CARB bearingsI am a bearing manufacturer, factory direct marketing, welcome inquiry cooperation. Contact information on personal data

- Q: Is the roller bearing and the bearing chamber movable in the tapered rotor motor?

- E in cylindrical roller bearing is the meaning of improving internal cage design, similar to the SKF cylindrical roller bearing EC form, this type of bearing than without E, is to strengthen the design, the roller is filled more larger to increase the load. From the load point of view, it is better to choose E.

- Q: How should I find the concentricity of cylindrical roller bearings after installation?

- So, in the machining process, try to use special fixtures and parts drawing in tol and other measures to avoid such a remedy".

- Q: What is called a semi convex roller, a fully convex roller, a logarithmic curve roller?

- The convex roller refers to the basic cylindrical or conical roller with a continuous micro convex radian in the plane containing the roller axis, and the logarithmic curve roller is also a convex roller, which belongs to a full convex roller;Convexity roller refers to the plane containing the axis of roller in the outer surface of a continuous convex curved basic cylindrical or conical roller, roller is logarithmic curve convexity roller, roller is all convex; convexity roller refers to the plane containing the axis of roller in the outer surface of a continuous convex curved basic cylinder or conical roller,The logarithmic curve roller is also a convex roller, which belongs to a full convex roller; a modified roller refers to a roller that has a slightly modified diameter at the end of the outer surface to prevent the contact between the roller and the raceway.

- Q: The thrust cylindrical roller bearings do not need the bearing seat, and the thrust bearings, shaft rings and seat rings on our unit are all in the bearing seat, often broken. The rotation of the 1. shaft in the bearing seat will not be affected, moreover, the shaft will have radial runout. 2. do not use the bearing seat, usually how to refuel?.Are there any field installation drawings or data on thrust bearings?. Thanks a million!

- Hello, I have sent a message to your mailbox, I hope you can help! Have problems you can contact us directly, Beijing Sheng Yi Huitian Electromechanical Equipment Co. Ltd

Send your message to us

Bearings double row cylindrical roller NN3032K

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords