Bearings double row cylindrical roller NN3032

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Double row cylindrical roller bearings

The rollers of the double row cylindrical roller bearing are usually guided by two flanges of a ring.

Because this assembly part composed of cage, roller and guide ring can be separated from another

ring, the cylindrical roller bearing belongs to separable bearing. This type of bearing can be easily

mounted and dismounted. Its advantages are obvious especially when there is interference fits

between the inner, outer ring and the axis, housing.

This bearing is usually subjected to radial load, only the single-row bearing with inner& outer rings

flanges.

- NN double row cylindrical roller bearings

This kind of bearings with inner rid, no outer rid.This assembly part can be separated from another ring, and they have larger radial load capacity than other single row cylindrical roller bearings with the same size, but the axial or housing is free axial displacement, so this kind of bearings can only bear the axial load.

★ Product Features:

The rollers of the cylindrical roller bearing are usually guided by two flanges of a ring.

Because this assembly part composed of cage, roller and guide ring can be separated from

another ring, the cylindrical roller bearing belongs to separable bearing. This type of bearing

can be easily mounted and dismounted. Its advantages are obvious especially when there is

interference fits between the inner, outer ring and the axis, housing.

This bearing is usually subjected to radial load, only the single-row bearing with inner& outer

rings flanges can bear small steady axial load or great intermittent axial load. It has a high

requirement on the processing of the fitting parts such as axis and housing bore, etc.

★Product Application:

Cylindrical roller bearings are mainly used for:

- Iron and steel metallurgical industry

- medium and large motor

- generator

- combustion engines

- gas tuibine

- machine tool spindle

- speed reducer

- loading and unloading machinery and all kinds of industrial machinery

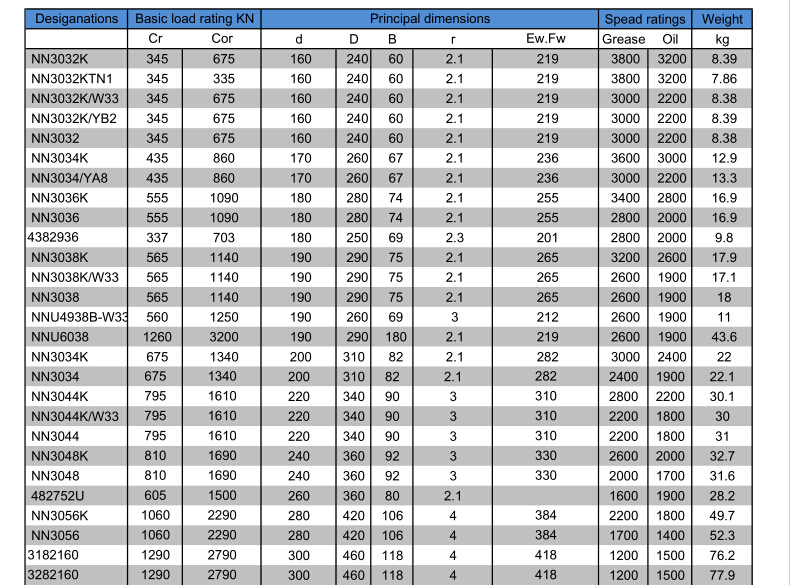

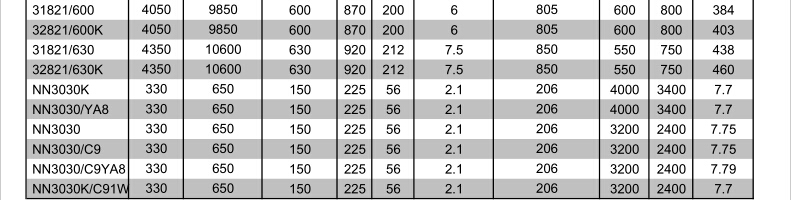

Double Row Cylindrical Roller Bearings Catalogue

- Q: Why are cylindrical roller bearings suitable for traveling support?

- Should be the inner ring and the outer ring without the edge of the can do moving support.

- Q: Can the Nu and N type NJ NUP cylindrical roller bearings bear axial force?

- The answer upstairs is clear. Such bearings can not be designed with axial force. In use, the inner and outer rings of the bearing can have larger axial displacement, and the aim is to compensate the length change caused by the rotating part of the two bearing due to the temperature rise.

- Q: In the car there is a cylindrical roller, the size of the diameter of 25mm, the outer diameter of 32mm, width of 9.5mm, who knows what the standard size, have direct purchase Mody, thank you!

- Hello, according to the data you supplied, and the type of bearing you saidAfter my inquiry,Cylindrical roller bearings, without this specification, GB specifications are 25 diameter, 52 outer diameter height, 15 model is nu205eAlso, the inside diameter is 25, the outside diameter is 62, the height is 15. The model is nu305eGB specifications, I have herecontactLook at personal data

- Q: What is the limit speed and rated dynamic load of NSK full M40-19g cylindrical roller bearings, HTF?

- NSK bearing type suffix solution of NSK bearing type by the basic code, prefix and post code, the basic code bearing series (including type) diameter and contact angle; pre code specific bearing; post code structure shape, bearing size, material, seal, retainer, clearance, heat tolerance processing, lubrication, change and other technical requirements, in addition to the basic code added after bearing code. NSK bearing model prefix F - deep groove ball bearing with flange outer ring (for D less than 10 mm), for example: F605. HR - high load tapered roller bearings, for example: HR30207J. MF - Flanged, outer race, deep groove ball bearings of specified sizes (D less than 10 mm), MF52. MR - deep groove ball bearings of specific size (for D less than 10 mm), for example: MR31. NSK bearing type rear code (1) internal structure A - internal design and standard different bearings. A - angular contact ball bearings with a contact angle of 30 degrees. A5 - angular contact ball bearings with a contact angle of 25 degrees. B - angular contact ball bearings with a contact angle of 40 degrees. C - angular contact ball bearings with a contact angle of 15 degrees. C - tapered roller bearings with a contact angle of 20 degrees.

- Q: Attention problems of cylindrical roller bearings

- 1. The installation of bearings must be carried out in a dry, clean environment. Before installation, the machined surface of the shaft and shell, the shoulder end, the groove and the joint surface shall be carefully inspected. All mating surfaces must be carefully cleaned and removed, and the cast surface must be clean. 2, before the installation of bearings, should be cleaned with gasoline or kerosene, dry after use, and ensure good lubrication, bearings generally grease lubrication, oil lubrication can also be used. Grease lubrication, grease, anti rust, extreme pressure and other excellent greases should be used. Grease filling capacity for bearings and bearing box volume of 30%-60%, should not be too much. Double row tapered roller bearing and water pump shaft bearing with sealing structure have been filled with grease, which can be used directly by users and can not be cleaned again. 3, bearing installation, must be applied equally in the circumference of ferrule end face pressure to press into the ring, and may not directly tap bearing end face to the top tool, so as not to damage the bearing. Small amount of interference in the case, at room temperature can be used to suppress sleeve bearing ring face, beating with a hammer sleeve, the sleeve will be pressed into the ring balance. If installed in large quantities, use hydraulic press. When pressing, the outer end surface of the outer ring and the outer shoulder of the shell face shall be ensured, and the inner ring end face is tightly pressed with the shoulder end of the shaft platform, and no gap is allowed.

- Q: What does "cylindrical roller bearing" ENV mean?

- Cylindrical roller bearings, the basic model suffix ENV meaning:E: enhanced design with improved bearing load capacityN: the outer ring of the bearing is provided with a stopping grooveV: full installed roller (no cage)

- Q: Cylindrical roller bearings, in the grease after the operation for a short period of time, the grease was thrown out (thrown to the end cap), resulting in roller and raceway between the lack of grease, lubrication poor. Decomposition found that the roller has round circumferential friction marks, but also on the roll, but compared to the roller is very slight. And there are relatively sound bearings, abnormal sound.Is this phenomenon normal? What if it doesn't work? What was the reason? What's the solution? StopThanks for your help!Assuming the grease is no problem, viscosity, consistency, selection is no problem If exclusion is the problem of grease, what other reasons can this be the case? ?

- Normal phenomenon: your choice of grease is too thin, choose a high degree of consistency. 2: mechanical revolution is too fast. 3: Grease adhesion is not high. Three possibilitiesHangzhou Xingang Petrochemical Co., Ltd. specializes in producing and selling grease and lubricating oil. Tip answer

- Q: Cylindrical roller bearingWhat are cylindrical roller bearings, are they available in Kunshan?

- The utility model is suitable for occasions where the bearing requirement is higher.

- Q: Thrust cylindrical roller bearings, the main use?

- Thrust cylindrical roller bearings, the main use? Thrust cylindrical roller bearings are mainly used in oil rigs, iron, steel, machinery and so on. Our factory uses the bearings of Changzhou Enke Bearing Co., Ltd., they have many kinds of bearings and meet various demands.

- Q: Why should the main shaft be coupled with double row cylindrical roller bearings?

- Because double row cylindrical roller bearings with high carrying capacity, high precision, separation, easy installation and disassembly, mainly used in lathes, milling machines, machining centers and other high-precision machine tool spindle. Hope to be of help to you.

Send your message to us

Bearings double row cylindrical roller NN3032

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords