Bearing Four Row Cylindrical Roller Bearing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

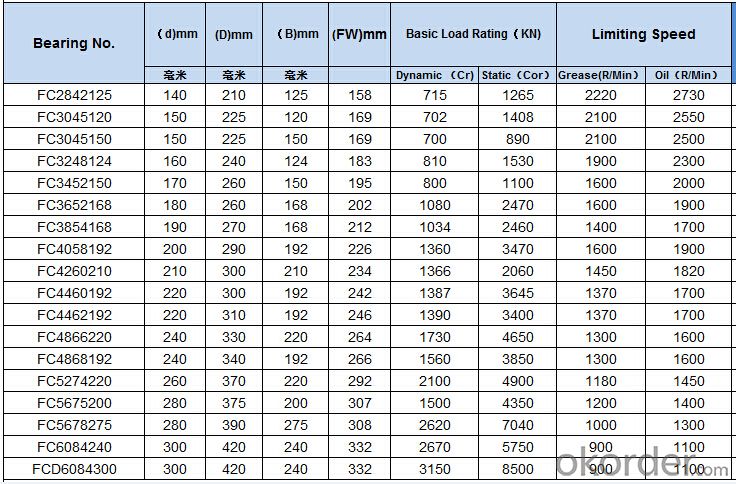

Four Row Cylindrical Roller Bearing

| Name | Four Row cylindrical roller bearing | ||||||||||||

| Type | Roller | ||||||||||||

| Materials | GCr15 | ||||||||||||

| cage's material | Steel,Brass | ||||||||||||

| Place of original | Shandong,China(Mainland) | ||||||||||||

| Seals type | Open,Sealed | ||||||||||||

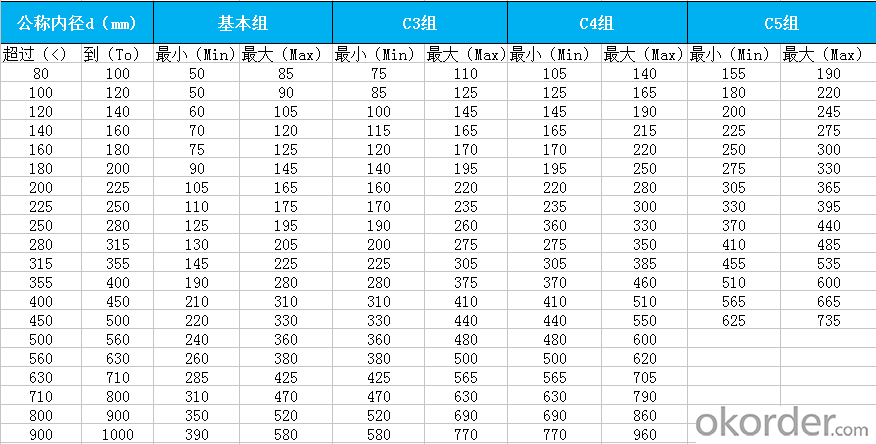

| Clearance | C0,C1,C2,C3,C4,C5,C6 | ||||||||||||

| Precision | P0-P6 | ||||||||||||

| Feature | This is consisted of an inner and other ring with a cage containing a complement of precision balls. | ||||||||||||

| Main application | Automobile,electrical equipment,instruments,agriculture machinery and many kinds of special machinery. | ||||||||||||

| Brand | OEM,ODM | ||||||||||||

| Market | America,Middle East,Southeast Asia,Brazil | ||||||||||||

| Quality level | AA+,A,B,C | ||||||||||||

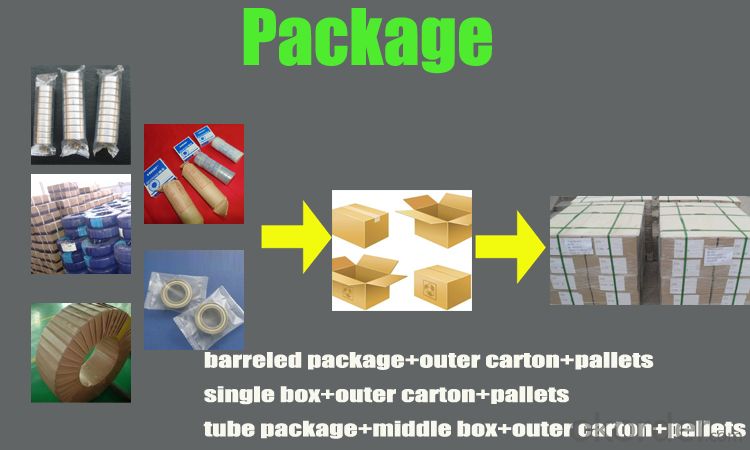

| Package | 1,barreled package+outer carton+pallets | ||||||||||||

| 2,single box+outer carton+pallets | |||||||||||||

| 3,tube package+middle box+outer carton+pallets | |||||||||||||

| 4,According to your requirement | |||||||||||||

| MOQ | 10PCS | ||||||||||||

| Port | Qingdao | ||||||||||||

| Payment Terms | T/T,PAYPAL,WESTERN UNION | ||||||||||||

| Delivery time | 5-25days,According to QTY | ||||||||||||

Features

1.) Offers a complete range, both metric and inch sizes available in metric and

imperial bore sizes ranging from 12 to 1320 mm.

2.)High radial load capacity - making cylindrical roller bearings suitable for high

speed applications.

3.)Designs - designated NU, NJ, NUP, N or NF for single row bearings and NNU or

NN for double row types, defines the bearing ring rib configuration.

4.) Cages - Available with pressed steel, machined brass and polyamide cages

throughout the range.

5.) Special designs - manufactures a range of four-row cylindrical roller bearings,

primarily designed for use as steel mill roll-neck bearings.

6.)Bearings are also available with both lubrication holes and a machined

lubrication groove on the outside surface of the outer ring.

Package

Factory

- Q: KOYO cylindrical roller bearings, //KOYO cylindrical roller bearings, how to determine the accuracy level?

- Bearing accuracy grade standards for, divided into 0, 6X, 6, 5, 4, 2, six grades.The accuracy of bearings is increased in order of magnitude 0, which is adequate for general 0, but requires 5 or higher accuracy when used in other conditions or situations.In most cases, it is sufficient to apply KOYO bearings (tolerance grade PN) with general dimensional accuracy and rotational accuracy. When higher requirements are required, the bearings require higher levels of accuracy, for example, the spindle axis of the machine toolBearing. In order to achieve higher precision requirements, the standard specifies the tolerance levels of P6, P6X, P5, P4 and P2. KOYO also specified P4S, SP and UP tolerances for some special bearings in accordance with company standards.

- Q: Full use cylindrical roller bearings, uses and advantages?

- In order to make the bearings work properly, the bearings must withstand a minimum load, i.e., C/P<25, in continuous operation.

- Q: Attention problems of cylindrical roller bearings

- 1. The installation of bearings must be carried out in a dry, clean environment. Before installation, the machined surface of the shaft and shell, the shoulder end, the groove and the joint surface shall be carefully inspected. All mating surfaces must be carefully cleaned and removed, and the cast surface must be clean. 2, before the installation of bearings, should be cleaned with gasoline or kerosene, dry after use, and ensure good lubrication, bearings generally grease lubrication, oil lubrication can also be used. Grease lubrication, grease, anti rust, extreme pressure and other excellent greases should be used. Grease filling capacity for bearings and bearing box volume of 30%-60%, should not be too much. Double row tapered roller bearing and water pump shaft bearing with sealing structure have been filled with grease, which can be used directly by users and can not be cleaned again. 3, bearing installation, must be applied equally in the circumference of ferrule end face pressure to press into the ring, and may not directly tap bearing end face to the top tool, so as not to damage the bearing. Small amount of interference in the case, at room temperature can be used to suppress sleeve bearing ring face, beating with a hammer sleeve, the sleeve will be pressed into the ring balance. If installed in large quantities, use hydraulic press. When pressing, the outer end surface of the outer ring and the outer shoulder of the shell face shall be ensured, and the inner ring end face is tightly pressed with the shoulder end of the shaft platform, and no gap is allowed.

- Q: What is the maximum rotational speed of a single row full cylindrical roller bearing?

- FAG full cylindrical roller bearings are especially suitable for ultra high load and medium speed applications. Sealed single row and double row bearings are mainly used in transmission mechanisms, while sealed double row bearings are more suitable for lifting mechanisms. Single row full roller cylindrical roller bearings, in addition to the NJ23VH series, can not be separated. The two rings of the separable bearing can be tightly matched so that it is easy to install and disassemble.

- Q: cylindrical roller bearings N210 20Deep groove ball bearings 6120, self-aligning ball bearings 1210, cylindrical roller bearings N210 in the same radial force conditions, the life expectancy of the three levels and how to compare? What is the cause of the high and low?

- The cylindrical roller bearings are in line contact with the outer ring of the bearing, and have the largest contact surface with the outer ring of the bearing. And the large contact surface means that in the same radial force, the same speed, friction, and thus generate more heat, and thus affect the life.

- Q: For bearing type, no outer ring single row cylindrical roller bearings, bore 40, thickness 21, roller diameter 8, roller length 12

- Hello, according to your descriptionCylindrical roller bearings NN3008-AS-K-M-SPAccording to the main dimensions of the DIN 5412-4 standard, non locating bearing, double row, with taper hole taper 1:12, can be separated, with cage, radial internal clearance decreased, tolerance limitInternal diameter D 40 mmOuter diameter D 68 mmThe thickness is B 21 mmDa Max 63 mmDb min 62 mmD1 50,6 mmDa min 45, mm, DS, 3,2, mmE 61, mmNS 4,8 mmRA Max 1 mmRmin 1, mmS 1,4 mmAxial offset from the center positionM 0303, kgqualityCr 45000, NBasic rated dynamic load, radialC0r 58500, NBasic rated static load radialNG Fett 12000 1/minLimit speed of grease lubricationNG l 15000 1/minLimit speed at least oil lubricationCur 8400, NFatigue limit load, radial

- Q: What's the difference between imported bearings and imported bearings?

- The 2 kind of bearing retainer material is mostly copper, and the retainer pin is also copperThere is also a steel retainerImported bearings also have copper and steel

- Q: What does "cylindrical roller bearing" ENV mean?

- Cylindrical roller bearings, the basic model suffix ENV meaning:E: enhanced design with improved bearing load capacityN: the outer ring of the bearing is provided with a stopping grooveV: full installed roller (no cage)

- Q: Rolling bearing face to face or back to back on the use of cylindrical roller bearing pairs, the speed limit will be reduced? Please, thank you!

- Generally speaking, the reduction of the limit speed is positive. As for radial loads, the two bearings are not multiplied by 2. on the carrying capacity of a single bearing, and the coefficient is different for each company.

- Q: Cylindrical roller bearings, in the grease after the operation for a short period of time, the grease was thrown out (thrown to the end cap), resulting in roller and raceway between the lack of grease, lubrication poor. Decomposition found that the roller has round circumferential friction marks, but also on the roll, but compared to the roller is very slight. And there are relatively sound bearings, abnormal sound.Is this phenomenon normal? What if it doesn't work? What was the reason? What's the solution? StopThanks for your help!Assuming the grease is no problem, viscosity, consistency, selection is no problem If exclusion is the problem of grease, what other reasons can this be the case? ?

- Normal phenomenon: your choice of grease is too thin, choose a high degree of consistency. 2: mechanical revolution is too fast. 3: Grease adhesion is not high. Three possibilitiesHangzhou Xingang Petrochemical Co., Ltd. specializes in producing and selling grease and lubricating oil. Tip answer

Send your message to us

Bearing Four Row Cylindrical Roller Bearing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords