High Precision Four Row Cylindrical Roller Bearing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

High Precision Four Row Cylindrical Roller Bearing

| Name | Deep Groove Ball Bearing | ||||||||||||

| Type | Ball | ||||||||||||

| Materials | GCr15,Ceramic,Plastic,Chrome steel,stainless steel,carbon steel | ||||||||||||

| cage's material | Steel,Brass,Nylon,Iron, Copper | ||||||||||||

| Place of original | Shandong,China(Mainland) | ||||||||||||

| Seals type | Open,Sealed,ZZ,Z,2RS,RS | ||||||||||||

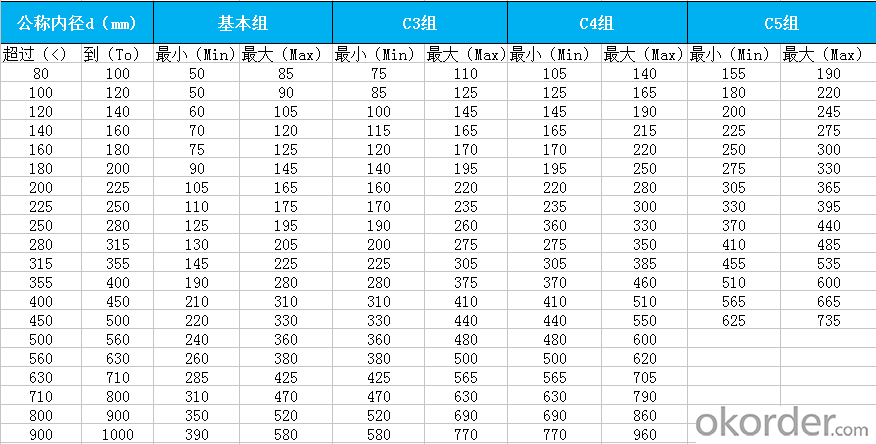

| Clearance | C0,C1,C2,C3,C4,C5,C6 | ||||||||||||

| Precision | ABEC-1 | ||||||||||||

| Feature | This is consisted of an inner and other ring with a cage containing a complement of precision balls. | ||||||||||||

| Main application | Automobile,electrical equipment,instruments,agriculture machinery and many kinds of special machinery. | ||||||||||||

| Brand | OEM,ODM | ||||||||||||

| Market | America,Middle East,Southeast Asia,Brazil | ||||||||||||

| Quality level | AA+,A,B,C | ||||||||||||

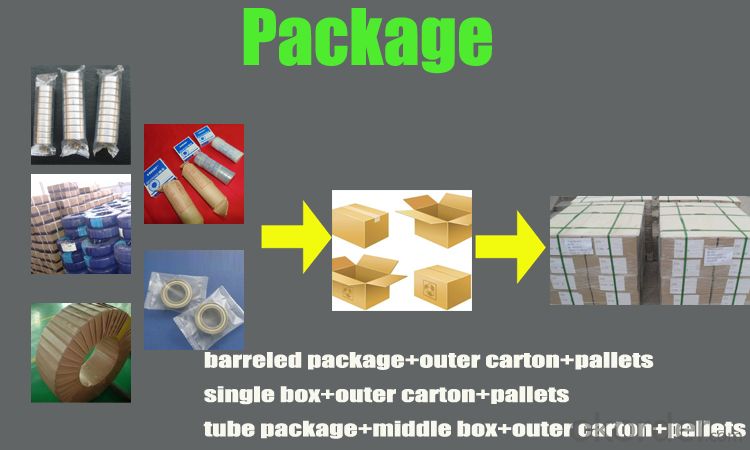

| Package | 1,barreled package+outer carton+pallets | ||||||||||||

| 2,single box+outer carton+pallets | |||||||||||||

| 3,tube package+middle box+outer carton+pallets | |||||||||||||

| 4,According to your requirement | |||||||||||||

| MOQ | 10PCS | ||||||||||||

| Port | Qingdao | ||||||||||||

| Payment Terms | T/T,PAYPAL,WESTERN UNION | ||||||||||||

| Delivery time | 5-25days,According to QTY | ||||||||||||

Features

1.) Offers a complete range, both metric and inch sizes available in metric and

imperial bore sizes ranging from 12 to 1320 mm.

2.)High radial load capacity - making cylindrical roller bearings suitable for high

speed applications.

3.)Designs - designated NU, NJ, NUP, N or NF for single row bearings and NNU or

NN for double row types, defines the bearing ring rib configuration.

4.) Cages - Available with pressed steel, machined brass and polyamide cages

throughout the range.

5.) Special designs - manufactures a range of four-row cylindrical roller bearings,

primarily designed for use as steel mill roll-neck bearings.

6.)Bearings are also available with both lubrication holes and a machined

lubrication groove on the outside surface of the outer ring.

Package

Factory

- Q: How are the twin row cylindrical roller bearings classified?

- Classification of double row cylindrical roller bearings:The NN0000 type cylindrical roller bearingsThe bearings are compact in structure and small in deformation under load, so they are especially suitable for the support of the spindle of machine tools. Because of its no outer wall, so you can install the outer ring and the inner ring assembly respectively (with roller and cage), does not limit the axial displacement of the shaft or housing, compared with the single row cylindrical roller bearing with the same radial size, can bear larger radial load.

- Q: Double row full cylindrical roller bearings, NNCF5008 installation, we need to pay attention to the direction of it?

- In theory, cylindrical roller bearings provide radial force, so there should be no direction.

- Q: Full use cylindrical roller bearings, uses and advantages?

- In order to make the bearings work properly, the bearings must withstand a minimum load, i.e., C/P<25, in continuous operation.

- Q: what does that mean? Please enlighten master, thank you.

- Hello, E on behalf of hanging behind the cage (black) steel cage; EM stands for copper holder.

- Q: What is the maximum rotational speed of a single row full cylindrical roller bearing?

- FAG single row full cylindrical roller bearingsFAG single row full cylindrical roller bearings can bear large radial loads, and can also bear single direction axial load. Axial positioning can be guaranteed by a symmetrical arrangement of similar bearings. NCF, 29V, NCF, 30V series of bearings have two fixed inner ring, the outer ring has a baffle, they can only bear the direction of the outer edge of the fixed axial load. The NJ23VH series bearings can bear the axial load toward the inside of the inner ring, and their rollers are fixed in the outer ring, even if the inner ring is taken away. The two rings are tight fit, easy installation and disassembly.

- Q: What are full cylindrical roller bearings?

- Full cylindrical roller bearingCommon cylindrical roller bearings1, single row full cylindrical roller bearingsNCFNJG2 、 double row full cylindrical roller bearingNNCLNNCFNNCNNFTwo, not common full cylindrical roller bearings1, full spherical cylindrical roller bearings2, CARB ring roller bearings

- Q: What are the components of cylindrical roller bearings?

- Compared with the deep groove ball bearings of the same size, this kind of bearing has larger radial load capacity, and is also suitable for high-speed rotation from the structure.

- Q: What is called a semi convex roller, a fully convex roller, a logarithmic curve roller?

- The convex roller refers to the basic cylindrical or conical roller with a continuous micro convex radian in the plane containing the roller axis, and the logarithmic curve roller is also a convex roller, which belongs to a full convex roller;Convexity roller refers to the plane containing the axis of roller in the outer surface of a continuous convex curved basic cylindrical or conical roller, roller is logarithmic curve convexity roller, roller is all convex; convexity roller refers to the plane containing the axis of roller in the outer surface of a continuous convex curved basic cylinder or conical roller,The logarithmic curve roller is also a convex roller, which belongs to a full convex roller; a modified roller refers to a roller that has a slightly modified diameter at the end of the outer surface to prevent the contact between the roller and the raceway.

- Q: Cylindrical roller bearings, in the grease after the operation for a short period of time, the grease was thrown out (thrown to the end cap), resulting in roller and raceway between the lack of grease, lubrication poor. Decomposition found that the roller has round circumferential friction marks, but also on the roll, but compared to the roller is very slight. And there are relatively sound bearings, abnormal sound.Is this phenomenon normal? What if it doesn't work? What was the reason? What's the solution? StopThanks for your help!Assuming the grease is no problem, viscosity, consistency, selection is no problem If exclusion is the problem of grease, what other reasons can this be the case? ?

- Normal phenomenon: your choice of grease is too thin, choose a high degree of consistency. 2: mechanical revolution is too fast. 3: Grease adhesion is not high. Three possibilitiesHangzhou Xingang Petrochemical Co., Ltd. specializes in producing and selling grease and lubricating oil. Tip answer

- Q: Full use roller bearings

- The FAG space division has also been involved in the development of bearings and other NTN precision components for Airbus wide body passenger aircraft A380 engines. The fuel efficient Boeing 787 aircraft reduces consumption by 20% compared to similar NACHI aircraft fuels, thanks to its improved aerodynamics, better operating systems and lighter materials. From the general electric KOYO GEnx engine and the Trent 1000 engine Rolls-Royce also play a role in ensuring that the airplane plays a key role more fuel-efficient. This high performance, lighter weight engine bearing support also plays a key role in the engine. FAG Aerospace entered the concept of bearing development, the engine as early as 2005. TIMKEN bearings, China's general agent, the first prototype manufactured bearings are available in 2006 to provide general electric and Rolls-Royce, FAG rolling bearing device design factors. The first engine test operation, which took place in the fall of 2006, achieved very positive results. The civil aviation authority's approval process for the two engines will be completed by the end of 2007.. In the summer of 2008, the first batch of FAG bearings was delivered to the airline. The main production base for the FAG China production base in Shanghai and INA roller bearing Chinese sales center, as well as Germany, Canada, Sweden SKF bearing China general agent of American Timken FAG office production base. The key role of space rolling bearing FAG in Rawls Royce and general electric engine plays, FAG bearing supply of Boeing 787 aircraft, Japan NMB bearings, the two engines for the new long haul aircraft rely on Aerospace Corporation of FAG rolling bearing

Send your message to us

High Precision Four Row Cylindrical Roller Bearing

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords