Alkali Resistant Fiberglass Mesh - High Quality, Low Price Battery Separator Mat

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

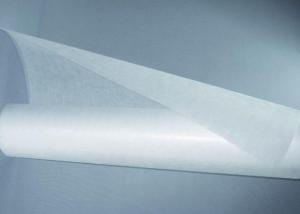

Fiberglass tissue mat

1)Fiberglass Tissue Mat for roofing

Roofing tissue mat is mainly used as excellent substrates for waterproof roofing materials. It is characterized as high tensile strength, corrosion resistance, easy soakage by bitumen, and so on. The longitudinal strength and tear resistance can be improved further by incorporating reinforcements into the tissue across its whole width. The waterproof roofing tissue made of this substrates is not easy to crack, ageing and rot. Other advantages of waterproof roofing tissue are high strength, excellent uniformity, good weathering quality and leaking resistance.

We can produce the goods from 40gram/m2 to 100 gram /m2, and the space between yarns is 15mm or 30mm (68 TEX)

2)Fiberglass Tissue Mat for flooring

Flooring tissue mat is mainly used as substrates for plastic flooring and wall covering materials. It features in uniform thickness, dimensional stability, non-deformation and non-distortion under high temperature, resistant against mildew and easy impregnation with resin coating. The PVB cushion and vinyl flooring made from flooring mat is an ideal decorative material for floor decoration in domestic residences on account of their characteristics such as smooth appearance, non-shrinkage, non-deformation, bright color, convenient lay-up and renovation. By further processing, flooring mat can be manufactured into a variety of colourful facing materials to be used in the internal decoration in elegant hotels.

3)Fiberglass Tissue Mat for pipe wrapping

Pipe wrapping mat is used as basic material for anti-corrosion wrapping on steel pipelines that buried underground for oil or gas transportation. It is characterized by high tensile strength, good flexibility, uniform thickness, solvent -resistance, moisture resistance, and flame retardation. It is well compatible with impregnation bitumen or coal tar enamel the oil of gas pipelines wrapped by Pipe wrapping mat pre-impregnated with bitumen or coal tar enamel acquire capabilities against leakage and aggressivemedia in the environment so that the cost for maintenance and replacement can be reduced significantly and the life time of pile-line may be prolonged up to 50-60 years authoritative tests have proven that the technical target of wrapping mat series can all meet or surpass the technical specification stated in SY/T0079, the oil and gas industry standard of the people's republic of china and meet the requirement in the specification of AWWA C 203 AS WELL this mat is an ideal base material as inner wrap or outer wrap or outer wrap impregnated by bitumen of coal tar enamel

4)Fiberglass Tissue Mat for FRP surface

FRP surface mat is mainly used as the surface layers of FRP products. It is characterized by uniform fiber dispersion, smooth surface, soft hand-feeling, lowbinder content, fast resin impregnation and good mould obedience. This line of product falls into two catalogues: Filament winding type CBM series and hand lay-up type SBM series

5)Fiberglass Tissue Mat for wall covering

Wall covering mat, a environment-friendly product made of chopped fiber glass by wet process, is mainly applied for the surface layer and the inner layer of wall and ceiling with the high function of fire-retardancy, anti-corrosion, shock-resistance, anti-corrugation, crack-resistance, water-resistance, air-permeability as well as elegant and noble decorative effects. It can be widely used in public entertainment place, conference hall, star-hotel, restaurant, cinema, hospital, school, office building and resident house.,

- Q: Mesh cloth tape, that is, fiberglass self-adhesive tape, how to use?

- Construction method:1. Keep the walls clean and dry.2. Put the adhesive tape on the crack and press it tightly.3, confirm the gap has been covered in tape, then tape the knife more she cut off, finally brush mortar.4. Let it dry naturally, then gently polish.5. Fill enough paint to smooth the surface.6. Remove the leaking adhesive tape. Then, note that all the cracks have been properly repaired, with fine composite materials will be modified around the patch, so that it is bright and clean as new.

- Q: Hydraulic oil filter, glass fiber or imported paper is good?

- Of course, this also means the use of glass fiber purifier, in the replacement of the filter, the price will be higher!

- Q: How to use gridding cloth tape, namely glass fiber self adhesive tape?

- 1. Keep the wall clean and dry. 2. Paste and press the tape on the crack. 3. Confirm that the gap has been covered with tape, and then cut the needless tape and paint with mortar. 4. Allow it to dry naturally, then polish gently. 5. Fill enough paint in and make its surface smooth. 6. Cut the leak-out tape. Then, check if all the cracks have been properly patched, and decorate the crack with subtle composite material to make it look clean and new.

- Q: What's the harm of glass fiber gridding cloth?

- Too itching. Some may cause skin allergy.

- Q: How much money do I need to run a small mesh loom factory ?

- A 2-meter-wide standard loom costs about ?12,000 each. 2 or 3 looms would be enough. You also need a drying oven, about ?10,005, a warping machine,about ?3,000, beating crusher costs ?2,000. Then you can start on.

- Q: What is specification for alkali-resistant fiberglass mesh?

- There are three kinds of alkali-resistant fiberglass mesh, different types have different specification. One, interior wall thermal insulation fiberglass: Mesh: 5mm * 5mm, 4mm * 4mm Weight:80g --- 165g /㎡. Width: 1000mm ---- 2000mm. Length:50m-300m. Second, the external walls thermal insulation mesh. Size: 5x5mm, 4x5mm or 4x4mm. Weight per square: 80g - 160g. Length: 50m, 100m or 200m. Width: 1m - 2m. Three, GRC reinforced mesh. Mesh size: 8mm × 8mm10mm × 10mm12mm × 12mm. Width: 60 cm, 90 cm, or 1 meter. Weight per square : 125g. Length: 100 m or 50 m

- Q: What functions does fiberglass wall mesh have ?

- Fiberglass wall mesh functions well. On the one hand, it can effectively increase the tensile strength of the protective layer, on the other hand, because the stress can be effectively dispersed, it can disperse original wider cracks into smaller ones, thus reaching the effect of anti-crack. Surface coating materials and coating amount has more important significance on alkali resistance of fiberglass mesh while glass?fiber has decisive significance on the long-term alkali resistance.

- Q: How to increase the glass fiber net fabric tensile strength

- You may use clay crucibles to wire the poor fiberglass mesh fabric

- Q: Who knows how to use glass?silk mesh?

- Before paving, the wall should be cleaned up, potholes should be patched, an then brush latex and pave meshes on the wall, meshes should be paved smoothly, the interval overlap should be at least 50MM. when the wall is wholly dried up, then move on with next step.

- Q: What is the difference between medium alkali glass fiber cloth and alkali resistant glass fiber cloth?

- As for the cloth and mesh cloth, just different weave, has nothing to do with the glass composition.

Send your message to us

Alkali Resistant Fiberglass Mesh - High Quality, Low Price Battery Separator Mat

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 5000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords