bathroom floor tiles passed CE, Germany standard,ISO9001

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

一. Structure of bathroom floor tiles

Item | bathroom floor tiles-- China 10 Years Experience Composite Decking Suppliers |

Material | Wood Plastic Composite |

Color | Cedar, Coffee, Brown, Black, Dark gray, Light gray, Red wood, Red pine, Yellow, or adjusted to customer's requirement |

Surface | Groove, Wood Grain, Sanding |

Length | 2.2m/pc, 2.9m/pc, 5.4m/pc |

Application | Terrace, Garden, Lawn, Balcony, Corridor, Garage, Pool & SPA Surrounds, Boardwalk, Playground |

Packing | PE Film + WPC Pallet (length of 0-2.2m) or Wood Pallet (length>2.2m) optional |

Certificate: | CE, SGS, CMTL |

二.Main Features of bathroom floor tiles

1. Eco-friendly, fully recyclable.

2. With natural wood grain, color and texture, looks like nature wood.

3. Waterproofing, fireproofing, Mildew-resistant, anti-UV.

4. Less cracking, less warping.

5. No need painting, no glue.

6. Can be planed, nailed, drilled and cut to any wanted size.

7. Weather resistant, suitable from -40 to 60°C.

8. Easy to install, clean.

9. Low maintenance, durable, economic, long lifetime

10. Anti-slip, less cracking, less warping.

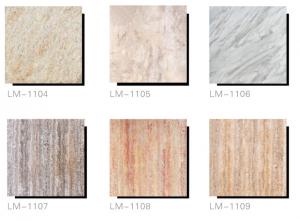

三. bathroom floor tiles

四.bathroom floor tiles Specification

Name | bathroom floor tiles |

Size | W*H=145*30 mm, can be customized |

Length | 2200mm, 2800mm, 4000mm, Customized |

Material | Wood Powder, HDPE, Additives |

Surface Finishing | Sanding, Brushing, Wood grain |

Certification | CE, Reach, Intertek, SGS, ISO, FSC |

Range of Application | Outdoor Flooring, Garden, Balcony, Terrace, Pool Surrounds, Boardwalk, Playground… |

五.FAQ of bathroom floor tiles

. What kinds of wpc products do you have?

We have wpc decking in different size, fence series (only wpc material or connect with aluminum profiles, decking tile series.

. Is it difficult to install the wpc board?

No, it is easy to install. Using the tool which you use to install the real wood. Fix the board on the substructure with clips.

. Can you stick the label with our logo on the boards?

Yes, please provide the label drawing, we can stick the customized label on the board.

. What documents are available?

A full range documents, including products pictures, installation guide and relative certificates can be provided; Further more, customs declaration is provided. This is an one-stop service for you.

- Q: My landlord in the balcony painted a thick paint, more than two months later, the smell is still very large, in order to health, and the landlord to negotiate, they agreed to remove the paint layer, but to keep the corner part. Now two days to remove the paint layer, but the smell is bigger. Now I want to purchase the floor, then at the boundary with plastic tape sticking. Do not know whether it can isolate formaldehyde, etc....

- No, formaldehyde removal method of Han purple is physical adsorption by palygorskite and sepiolite based, adding diatomite, tourmaline and other natural minerals, after special processing technology is made, in which the pore pore size between 0.27 - 0.98 nm and a crystal arrangement. At the same time is weak, formaldehyde, ammonia, benzene molecules, toluene and xylene in diameter 0.40.62 nm, and it is a polar molecule, so it has the features of preferential adsorption of formaldehyde, benzene, TVOC and other harmful gases, to purify indoor air effect

- Q: PVC floor glue what glue plastic floor glue

- Plastic flooring is a broad term. There are a variety of views on the network, it should be said is not very accurate, plastic floor is a very popular in the world today, a new type of light ground decorative materials, also known as "light material".

- Q: Construction process of soft plastic floor

- 2.1 material:2.1.1 cement: suitable for Portland cement, ordinary portland cement, the strength of the grade should be above 32.5; different varieties, different grades of cement is strictly prohibited mixed.2.1.2 sand: medium sand or coarse sand should be selected, the mud content shall not be greater than 3%.

- Q: Ask how to install plastic floor

- Tools: a knife blade, remove the plastic floor flat at room temperature for at least 24 hours, two on each side of the wall to find the center point, draw the cross center line on the floor, the ground is divided into four areas, and then from the central to the laying of three four, clean the ground, make sure the ground can begin after the laying of four, clean (without gum floor) with a scraper coated plastic tile special adhesive, five (Beijiao floor) tore the floor backing off the paper, starting from the six floor of the center line laying in all directions, each piece of tile must be close to the junction, glued to the ground, to avoid the gap seven, laying to the wall the floor tile cutting required size

- Q: Plastic floor coil and sheet are what size

- Sheet flooring specifications, mainly divided into strip and square. 457.2*457.2mm/152.4mm*914.4mm.

- Q: What is the name of the plastic floor on the supermarket, where is it?

- Plastic flooring selection coil special PVC glue, stairs, wall with adhesive

- Q: I asked about the "plastic" floor tile paving method, please describe its steps?

- The main steps: paste the repair of flat ground clean room, good paste compaction correction error spreading along the reference line from the center to spread around the pipeline at the box office, cutting method and cutting method of layering skirt

- Q: Is plastic floor glue toxic? Thank you

- Floor leather (toxic, mainly heavy metal exceed the standard): this kind of floor in black or dark bottom. Because of cheap, from 80s in China's mass production and application. Especially in the three northeastern provinces, a large number of people in the home are useful, with the promotion of commercial land in recent years, is now being reduced, and now the market is very environmentally friendly sales standards. Some are not under the environmental protection, but the surface is environmentally friendly, if there are children at home do not recommend the use of the more can not be used to artificial food mat

- Q: How to clean plastic floor

- 2, while the start of the water suction machine, while scrubbing the suction in addition to sewage, washing machine can not be washed to the plastic floor can be used to mop the dry cleaning detergent.

- Q: Home decoration, floor requirements should be very flat

- (3) affected by the temperature, the curing speed of the adhesive is slow, so it is necessary to use the pressure wheel repeatedly to prevent peeling(4) even after construction, it is easy to harden and soften due to the temperature difference at night or other temperature difference.

Send your message to us

bathroom floor tiles passed CE, Germany standard,ISO9001

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords