B4 Type PPR Ball Valve with Brass Ball with Brass Ball

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

Material: Plastic

Technics: Injection

Type: Valve

Place of Origin: Zhejiang, China (Mainland)

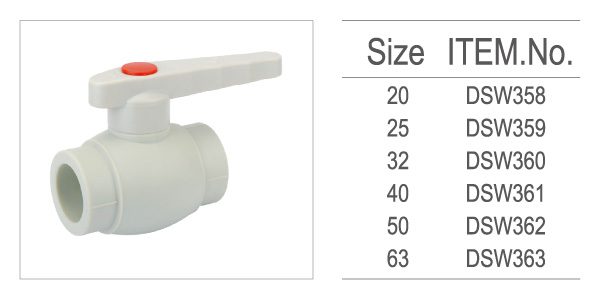

Model Number: DSW358-363

Connection: Welding

Shape: Equal

Head Code: Round

Standard: ISO,DIN,EN,MSS,API,BS,ANSI

Certification: ISO9001,CE

Specifications

Standard: DIN8077/8078

Material: R200P from Korea

Packaging & Delivery

Packaging Details:

1. Large carton:515x400x220 Cubage:0.04532 M3

Small carton:390x255x250 Cubage:0.0248 M3

2. PE poly bag+ cartonDelivery Detail: 15 days/ 20" container; 25 days/ 40HQ

Our Advantages:

1) Healthy, bacteriological neutral, conforming to drinking water standards

2) Resistant to high temperatures, good impact strength

3) Convenient and reliable installation, low construction expenses

4) Excellent heat-insulation property from minimum thermal conductivity

5) Lightweight, convenient to transport and handle, good for labor-saving

6) Smooth inner walls reduce pressure loss and increase flow speed

7) Sound insulation (reduced by 40% compared to galvanized steel pipes)

8) Light colors and excellent design ensure suitability for both exposed and hidden installation

9) Recyclable, environment-friendly, accords with GBM standards

Applications

> Distribution for cool and hot water;

> Duct for drinkable water system;

> Pipes for kinds of high-temperature and low-temperature heating system;

> Pipes for heating and coolling settings in solar energy system;

> Connecting pipe for air conditioners.

- Q: Spiral drain pipe fittings are not special pipe fittings

- NoThe drainage tube is made of high density polyethylene (HDPE) and other additives the exterior is a new drainage plastic pipe corrugated, corrugated pipe is through holes in the permeable groove tube around the outside of the outsourcing geotextile acupuncture and processing. According to the types of bellows, they can be divided into single wall permeable bellows and double wall permeable bellows.

- Q: What causes plastic pipes and fittings to burst easily?

- Generally, there are dimension indexes, inner diameter, outer diameter and wall thickness.Strength index, pipe strength indicators have radial compressive strength, that is, ring stiffness, flexibility index, bending index, impact strength, etc.For drinking water pipes, there are technical aspects of health indicators, as well as water pressure indicators.For the communications industry, there are other technical requirements.

- Q: What are the common installation methods for plastic pipe fittings?

- The common installation methods for plastic pipe fittings include solvent welding, compression fittings, push-fit fittings, and heat fusion.

- Q: When calculating the installation of water supply and drainage pipelines, are elbow and pipe fittings calculated separately?

- Water supply and drainage pipeline engineering, bends and fittings of the material shall be calculated separately, the installation fee is included in the pipeline installation quota, do not need to be calculated, such as industrial pipeline, the pipe installation fee plus

- Q: Can plastic pipe fittings be used for irrigation drip systems?

- Yes, plastic pipe fittings can be used for irrigation drip systems. Plastic fittings are commonly used in drip irrigation systems due to their durability, affordability, and resistance to corrosion. They provide a reliable and leak-free connection between pipes and drip emitters, allowing for efficient water distribution in the irrigation system.

- Q: Can plastic pipe fittings be used for stormwater infiltration systems?

- Yes, plastic pipe fittings can be used for stormwater infiltration systems. Plastic pipe fittings offer several benefits such as durability, corrosion resistance, and ease of installation. They are commonly used in stormwater management systems to connect and direct the flow of water, including in infiltration systems where water is collected and infiltrated into the ground to recharge groundwater.

- Q: How do you repair plastic pipe fittings?

- To repair plastic pipe fittings, you can start by turning off the water supply and draining the pipes. Then, carefully cut out the damaged section of the pipe using a hacksaw or pipe cutter. Next, clean the ends of the remaining pipe and the inside of the fittings with sandpaper or a pipe cleaner. Apply a primer to both the pipe and fitting, followed by a layer of PVC cement. Finally, push the pipe into the fitting, hold it in place for a few seconds, and allow the cement to dry completely before turning the water supply back on.

- Q: Are plastic pipe fittings resistant to electromagnetic interference?

- No, plastic pipe fittings are not generally resistant to electromagnetic interference.

- Q: Do plastic pipe fittings require maintenance?

- Yes, plastic pipe fittings generally do not require maintenance as they are durable and resistant to corrosion. However, occasional inspections and repairs may be necessary if there are any signs of damage, leaks, or blockages in the plumbing system.

- Q: Can plastic pipe fittings be used for reverse osmosis systems?

- Yes, plastic pipe fittings can be used for reverse osmosis systems. Plastic fittings such as PVC or CPVC are commonly used in these systems due to their durability, affordability, and resistance to corrosion. They are also lightweight and easy to install, making them a popular choice for reverse osmosis systems.

Send your message to us

B4 Type PPR Ball Valve with Brass Ball with Brass Ball

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 100000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords