Automatic Sectional Garage Door for Sale

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Each section panel's joint is adopt "Finger-protection"(Pinch-resistant) safety Design in order to avoid any finger injury when door open and close. The panel is injected with polyurethane foam(CFC FREE). Foam density is 40kg/m3 All the panels are produced by continued production line which provide the stable quality.

2. Special design of pinch-resistant, there is continued folding part along the panel,thus the panel can be cut at any size,the hinges can be installed accurately and firmly.

3. Wood-grain or stucco Texture surface increases intensity and gives better appearance

4. Thickness of the panel:40mm with the 0.326mm,0.40mm and 0.45mm

5. Max.width of the panel:11800mm

6. Section height: any size between 44-55cm

7 .40mm panel heat consumption factor:K=1.0W/m2k Heat consumption factor of the installed door:K=1.6W/m2k

8. standard and special colors for the selection

9. patterns for choice : blocks,stripes,H-line,smooth

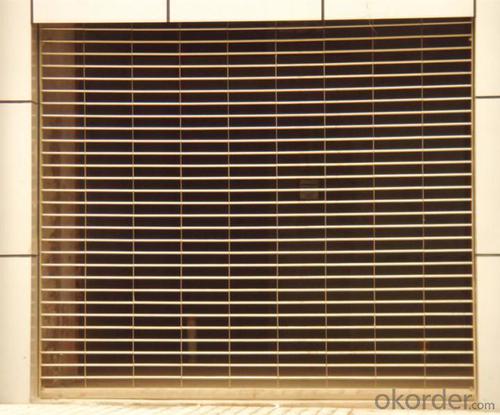

a, unique transparent, elegant anodized aluminum frame

b, thickness: polycarbonate thickness between 3mm to 9mm,tempered glass,mirror glass,single or dual pane are available

c, UV proof

d, impact-resistant and burglar-retardant

e, resistance to wind load :Class 3 Water-tightness:Class 3 air permeability:Class 2

f, more options are available: combination of materials in polyurethane and polycarbonate with the anodized aluminum frame,highly robust and durable hardwares

g, all the sections can be replaced easily

h, 200 times harder than normal glass, the door resist the impact of external force and will not easily be damaged,even under the harsh environment the door will not easily become deformed owing to corrosion

i, an effect of day-lighting, firm and smooth and could be used for a long time without maintenance

j, It is applicable to various modern, simple and fashionable architectural styles, such as commercial shops, chain-stores etc.

k, lift way: standard overhead,high lift,vertical lift

- Q: Buy aluminum door to how to choose, is not the more expensive the better? Home bathroom door bad, do not know what to change the door, see a lot of friends home doors are aluminum doors, I also want to buy,

- Cost-effective is always more important than the "high price".

- Q: The door is wooden, but the door frame is metal (I found out when the screw wouldnt go in no matter how I hammered it). Is there a way to install a hasp to put padlock on? (Are there screw drivers for metal surfaces?) Or is there any other way to have the door locked without having to installing a cylinder lock?

- You need to drill a hole first with a metal twist drill bit. Get a drill bit that is the same size as the screw shank (the solid part below the threads - the hole must be smaller than the diameter of the threads, so there is material for the threads to bite into), mark the location of the holes for the hasp on the frame, and drill the holes to the depth of the screws. Then attach the hasp.

- Q: hello, I thought Id brighten up my house by removing cleaning all the internal door handles. they are old fashioned, lever type, quite a heavy metal. I dont think theyre brass since they are very dark in colour. how can I: 1) clean them and then, could I possibly 2) paint them? a different, and bright colour? any help appreciated, thanks.

- try getting him on my own and then scream in his face I rebuke you interior the call of Christ! If he disappears in a cloud of smoke then that's devil. If he yells back asserting What the hell? then you definately've somewhat some explaining to do

- Q: If so, what is the best way to do that? What is the best type of paint to use on metal doors?

- No need to remove all the old paint. Scuff it up with sandpaper so the new paint can adhere. I like Latex paint on metal since it will expand and contract with the changing temperatures. This is what I use on metal siding.

- Q: Is the glass on the door only broken?

- You can change the change that you will have to look at your door is loaded with even the Kuang with glass together into the pressure or pressure If you go in, then the trouble of the big pressure on the pressure of the more easy to do the glass you go to the art of glass shop to carve a piece of glass and your original glass if you can not carve that you replaced with all white frosted him in the help You do something like a hollow I like to do the steel doors and windows of the way with the sale of kitchen and toilet door of this situation I have trouble to ask you your door in that buy you to find which home to help you repair you If you want to do the work of the whole glass frosted glass probably about 120 square a square it

- Q: Bathroom with titanium alloy door or aluminum titanium door good?

- The above said, the general titanium alloy inside the real titanium content is very small, no more than 3%, most of the aluminum, but aluminum inside the addition of these small amounts of titanium, can be a greater performance improvement, such as strength, toughness , Corrosion resistance, etc., on the personal views of titanium aluminum alloy (in fact, but also the content of titanium but nothing) on the line.

- Q: Does anyone know if I can replace 2007 wrangler half doors with full metal doors? Ive been looking around and cant seem to find any full doors so im not sure. And if you can, does anyone know where i can find them in aftermarket sales?

- hello and yes these doors are very interchangable im in the opsite position i have full doors and are lookin for the half doors and looking to trade or sell them! please email me back

- Q: The lock is too low.

- If your problem is just with the latch and not with the door actually scraping the ground, then remove the plate on the inside door frame. Mark where the lock is now hitting and reattach the plate in the lower spot. If something is obstructing the door then you'll have to move the obstruction.

- Q: i really cant find the asnwer someone help its for homework

- Lowri the only doors that do this are fire doors And these have a quick release handle to open them No other door should lock by itself

- Q: Aluminum alloy doors and windows need to pay attention to what the problem, how to solve?

- Daily use of aluminum doors and windows sometimes found around the wall connection with the Department of leakage, especially under the window angle is more common; followed by the combination of the windows of the splicing Department of water seepage. Corresponding measures: 1. Because of the thermal expansion coefficient of the aluminum alloy and the wall material, under the influence of temperature, the frame body is easy to produce capillary cracks with the wall connection. In order to prevent the seepage at the cracks, aluminum doors and windows with the wall should be done in a flexible connection, the construction should be clear at the junction of the floor of the floating ash, mortar particles and other debris, and then inside and outside the box with the wall connection Sealant for sealing, glue to be continuous, do not miss, stick to be strong. 2. To the exposed connection screws, but also with a sealant buried seal, to prevent water seepage.

Send your message to us

Automatic Sectional Garage Door for Sale

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords