Automatic Multi-Layer Bottom-Pasted Paper Bag Making Machine

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 0.2 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

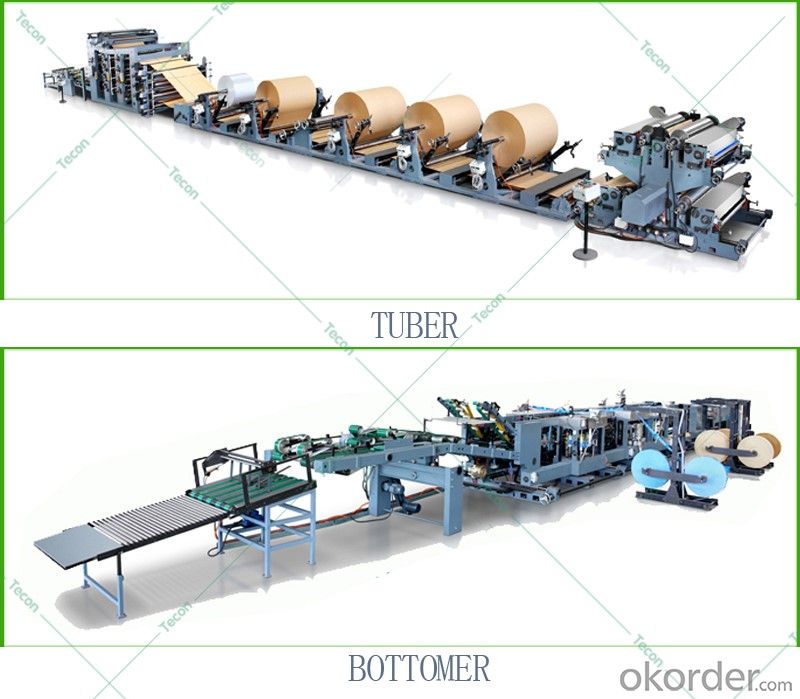

Our paper bag production line consists of paper tube forming machine(Tuber) and bottom pasting machine(Bottomer). The products-Valve bags are used for a vast number of applications, primarily in the building materials and food industries, to filling goods such as:cement,chemical material, feeds, fertilizers,tea,rice etc.

Our Advantage:

1.Specialize in design and manufacture valve paper bag machine for 30 years;

2.CE Certified;

3.Our tuber machine and bottomer machine have gained over 50 utility model patents;

4.Longer service life with NSK bearings,SIEMENS control system and high quality gearings.

5.Cost effective compare to W&H,Germany and Newlong,Japan.

Valve paper Bags:

Different models can produce different kinds of bags,like standard cement bags,chemical/cement bags with bottom strengthen sheet,tea bag with PP Liner to enhanced moisture protection.

Bags can be made of 2~4 layers kraft paper or paper with one layer of PE/PP film.2~4 colors printing available in Tuber line.

The bags opening or valve in one corner through which the sack is filled. The valve is made with an inner flap which functions as a self-closing check valve after filling. It is available with a plain valve or with an extended inner sleeve of paper or film.

Machine Technical Parameters:

| Running Speed | 80~130 bags/min |

| Bag length | 520~880mm |

| Bag width | 420~600 mm |

| Bottom width | 90~130mm |

| Bottom open width | 200~380mm |

| Distance between bottom centers | 420~780mm |

| Valve sheet length | 100~250mm |

| Valve sheet width | 120~170mm |

| Main drive motor | 33kw |

| Total weight | 22.7T |

| Size of whole set | 21.3m×2.3.m×1.8m ( L×W×H) |

Product show:

After-sale service

1.Provide training during and after the commissioning at the buyer site.

2.One year warranty period from the acceptance at the buyer site.

3.Provide life long technical services and effective solutions.

- Q: Carton packaging in the form of technology, including several major categories

- Raw material is pulp, general corrugated paper, more used for holding items, recyclable. Packaging of paper products is the largest quantity used in packaging industry. Carton is the most important form of transport packaging, and cartons are widely used as food, pharmaceutical, electronic and other products for sale and packaging. With the change of the mode of transportation and sale mode change, carton, carton style diversification, almost every kind of non-standard cartons are accompanied by a set of automation equipment, and the novel carton itself, has become a commodity promotion means

- Q: Ask some books about packing machinery. Especially about carton forming

- Two, with ink printing slotting machine, printing, indentation, cutting angle, slotting, edge separation. Primary molding.Three, the nail box machine or glue will be processed pieces of paper glued to the common carton.Four, ten or several bundles, send away.

- Q: What are the processes required for imported food packaging equipment?

- First, if the new machine is, only goods import port, customs clearance, tax, tax, audit, customs inspection and release! The process is simple, without inspection, no automatic import license!

- Q: How much is the gas consumption per EPS molding machine per hour?

- Automatic vacuum packaging foam molding machine, ICF thermal module molding machine, hydraulic press automatic molding machine, and foam raw material manufacturer (dragon company) jointly developed the forming process, the process of forming speed, saving steam, products of good quality, shorten the drying time.

- Q: What are the forms of packaging and the forming process of textiles? The more detailed, the better

- If the elastic cloth will do 2 cm, root number and less easily according to the finished edge, density, edge width you can calculate the number of root selvage

- Q: What are the sensory standards in the hygienic standard for polyethylene used in food packaging?

- Poly (ethylene terephthalate) for food packagingPETBottle blankOneRangeThis standard specifies polyethylene terephthalatePETRequirements, testing methods, inspection rules, labelling, marking, packaging and transportation of containersAnd storage.This standard applies to bottle used polyethylene glycol terephthalate

- Q: Would you like to ask what is the difference between a cold stamping foil and a plain foil wrapper?

- 4., with metallic luster, light shielding, light reflection ability, luminous rate of 95%5., not easy to corrosion, barrier good, moisture-proof, waterproof, airtight, and has fragrant incense6. high temperature and low temperature stable shape, temperature [1] expansion in -73~371 ~ C deformation

- Q: Ask: how to improve the strength of PP sheet, used to absorb the molding of the coil, need to meet the requirements of food packaging, and food direct contact.

- Change to copolymerization PP material, Nordic chemical, some brands are available

- Q: What are the characteristics of plastic thermoforming?

- Thin to0.1mmMost of the hot forming products are concave, convex, semi shell, and their depth is limited. Most of the hot forming parts are thin wall, and the thickness of the original sheet is0.2mmThe thickness of the actual product is smaller, and the thickness of the special thin product is up to0.05mm.2.A wide range of applications. Due to the thermal molding adaptability, its scope of application. From the tablet packing to the refrigerator liner, even to the aircraft hatch cover, can be obtained by thermal moulding method. A cup dish and other household utensils, utensils, medical electronic instrument accessories, radio and TV, billboards, bathtub enclosure and toys and other products. - packaging type. Another car components of building components, chemical equipment, radar cover and aircraft cabin cover tray.3.Equipment investment is low. Because of the simple molding equipment and the low total pressure required, the requirement of pressure equipment is not high, so the thermoforming equipment has the characteristics of low investment and low cost..4.

- Q: Why should heat treatment be made after glass molding?

- Glass itself is very fragile, forming after the general empty, cold for a period of time, so that it has a certain intensity

Send your message to us

Automatic Multi-Layer Bottom-Pasted Paper Bag Making Machine

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 0.2 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords