Automatic Valve Paper Bags Making Machine Price

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 0.2 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

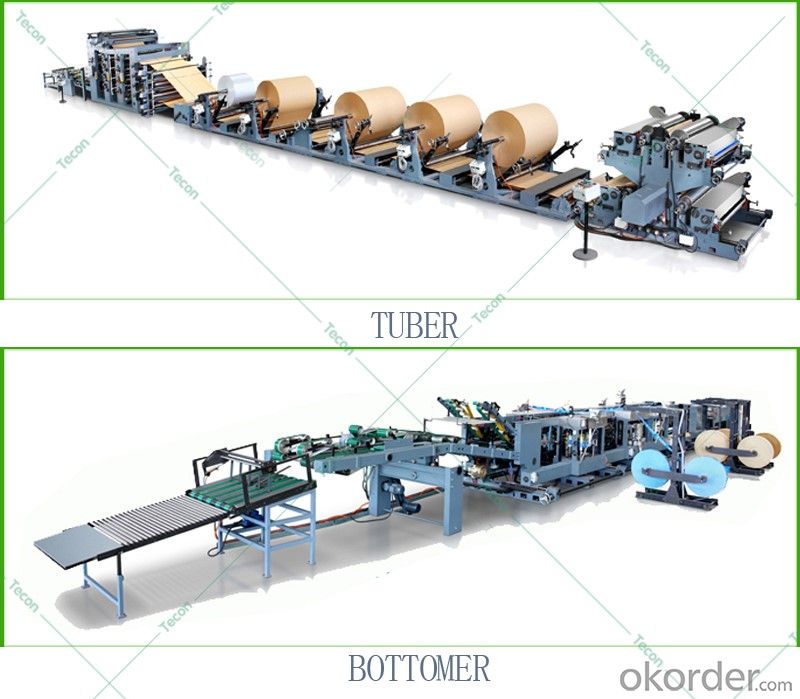

Our paper bag production line consists of paper tube forming machine(Tuber) and bottom pasting machine(Bottomer). The products-Valve bags are used for a vast number of applications, primarily in the building materials and food industries, to filling goods such as:cement,chemical material, feeds, fertilizers,tea,rice etc.

Our Advantage:

1.Specialize in design and manufacture valve paper bag machine for 30 years;

2.CE Certified;

3.Our tuber machine and bottomer machine have gained over 50 utility model patents;

4.Longer service life with NSK bearings,SIEMENS control system and high quality gearings.

5.Cost effective compare to W&H,Germany and Newlong,Japan.

Valve paper Bags:

Different models can produce different kinds of bags,like standard cement bags,chemical/cement bags with bottom strengthen sheet,tea bag with PP Liner to enhanced moisture protection.

Bags can be made of 2~4 layers kraft paper or paper with one layer of PE/PP film.2~4 colors printing available in Tuber line.

The bags opening or valve in one corner through which the sack is filled. The valve is made with an inner flap which functions as a self-closing check valve after filling. It is available with a plain valve or with an extended inner sleeve of paper or film.

Machine Technical Parameters:

| Model | ZT9802S |

| speed | 120 tubes/min |

| Tube Width | 380~620mm |

| Tube length | 400-1400mm |

| Specification gear | 51~80 teeth(M=4) |

| Type of cutting | Step cut&Flat cut |

| Number of ply | 2~4paper+ 1 PP/PE |

| Diameter of print roller | Ø196~ø312 mm |

| Printing width | 1300 mm(MAX) |

| Paper reel diameter | Max. 1, 300 mm |

| Paper reel width | 860--1260mm |

| Main drive motor | 47KW |

| Servo system | YES |

| Machine size | 35.32.42.7(M) |

| Machine weight | N 32(T) |

HD4916BD Bottomer Machine

| Model | HD4916BD |

| Speed | MAX 100/140 bags/minute |

| Tube Width | 380~600 mm |

| Bottom Width | 80~160 mm |

| Valve Sheet Length Width | (100-300)(120-240)adjustable |

| Bag Length | 520~880 mm |

| Bottom Center Distance | 420~780 mm |

| Number of ply | 2~4paper+1 PP/PE |

| Strength sheet unit | YES |

| Strength sheet length*width | (300~600)(80~160) |

| Main Drive Motor | 40KW |

| Machine size | 23/281.81.8(M) |

| Machine weight | N34(T) |

Product show:

After-sale service

1.Provide training during and after the commissioning at the buyer site.

2.One year warranty period from the acceptance at the buyer site.

3.Provide life long technical services and effective solutions.

- Q: The price of kneeling single station hollow blow molding machine;

- It began to be used in the production of LDPE vials. In the late 50s, with the birth of high-density polyethylene and the development of blow molding machine, blow molding technology has been widely used. Hollow containers can be thousands of liters in volume, and some have been computerized. The plastics suitable for blow molding are polyethylene, polyvinyl chloride, polypropylene, polyester, etc. the hollow containers obtained are widely used as industrial packaging containers.

- Q: Ask some books about packing machinery. Especially about carton forming

- Color box production processFirst, the printing press used offset printing to complete the printing of facial tissues.Two, paper by laminating machine or coated paper or polishing machine polishing, increased light, moisture.Three, the paper and corrugated cardboard laminator (by laminating machine) or adhesive glue machine.Four, through die cutting machine die-cutting.Five, the molding of cardboard with nail box machine or glue glued to the common carton.Six, ten or several bundles, send away.

- Q: Our company is a PCB drilling machine and forming machine, and recently there are several customer inquiries about which machines and PCB PCB manufacturing processes are needed to open the plant

- Screen printing text: through web printing or ink to form text, easy to welding identification;Surface treatment: tin spraying, gold deposition, OSP, gilding and so onElectrical test: test whether the PCB has an open short circuitMolding: numerical control, stamping formingPacking: vacuum packing, avoid scratch and oxidation!

- Q: PVC double wall corrugated tube forming machine computer screen shows down drive servo abnormal. What's the matter?

- Transmission machine(1) extruder is divided into 1 extruder (SBG500:90 extruder, SBG1000):120 extruder) 2 extruder (SBG500:65 extruder, SBG1000:90 extruder) usually needs heating for more than 3 hours. The main working parts of extruder are screw (single screw), the ratio of length to diameter of the first two screws is 30:1, and the length of the latter two screw is 33:1. (2) extrusion head, from inside and outside the screw and the internal branch of the shuttle and the internal and external die, heartMembrane composition. Accessories: normal gas filling, inner lining flushing, inner layer vacuum, inlet pipe and backwater pipe, 5 pipelines: the heating of the nose usually takes more than 6 hours

- Q: Blow molding process conditions The purpose of the adjustment of technological conditions is that,

- Use the established computer model to simulate the status of blow molding die, blanking billet and clamp plate;Enter the parameters affecting the wall thickness distribution of parison at each stage;The simulation results are analyzed, and computer simulation shows that the wall thickness is not enough, and which parts are super thick;

- Q: What are the forms of packaging and the forming process of textiles? The more detailed, the better

- If the elastic cloth will do 2 cm, root number and less easily according to the finished edge, density, edge width you can calculate the number of root selvage

- Q: What kind of equipment do you need for washing powder packaging bags, a production line, starting from the membrane, what kind of blowing machine, etc., and finally formed into washing powder packaging bags

- Do it yourself, process equipment are many, and later is the printing of composite bag, if necessary, but also cut

- Q: Foam box production equipment, where is the production of seafood boxes, such as foam box machine?

- (but the leadership of the company are basically old industry employees, so it can be said that the bridge industry is Great Wall Co mold center's predecessor) when just beginning to go to a month of military training, this is the the Great Wall tradition, basically can not be changed. Very tired drop! Just go, must be the next workshop, should be to stamping, the equipment is relatively old, is still very backward, can not be compared with the manufacture of three, let alone the new factory in Tianjin.

- Q: Would you like to ask what is the difference between a cold stamping foil and a plain foil wrapper?

- The specific technological process of producing aluminum foil is determined by the kinds of alloy, finished product specifications, product quality requirements, yield, specifications of production equipment and production capacity

- Q: Order a thermal packaging machine to the manufacturer. What information does half of the material need to provide to the packaging machine manufacturer?

- You need to pack the material, preferably the weight of the material, and if it is powder, how much moisture, good fluidity, also need to provide the size of packing bags, my name

Send your message to us

Automatic Valve Paper Bags Making Machine Price

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 0.2 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches