ASTM API 5LCold Drawn Seamless Steel Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We are company that have many years experience and professional manager team and engineer team and sales team, sure we will provide you high quality of pipe and professioanl service.

Seamless pipe possesses a hollow section and without seam around the strip steel. It is made with solid bar or steel ingot by perforating machine. As the facture process does not include any welding, seamless pipes are considered to be stronger and more durable. Generally speaking, seamless pipe has better pressure resistance and security than other classifications, and was usually more easily available than welded pipe.

2、Main Features of the Seamless Pipe:

• High working accuracy

• High strength

• Small inertia resistance

• Strong therming dissipine ability

• Good appearance

• Reasonble price

3、Seamless Pipe Specification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range: OD: 21.3-610mm, WT:6-70mm, length:6-12m or according to the requirement of clients.

3) Executive standards: GB, ASME API5L.ASTM A 106/A53,Despite of the above standards, we can also supply seamless steel pipe with standard of DIN, JIS, and so on, and also develop new products according to the requirements of our clients!

4) Surface: black lacquered, varnish coating or galvanized.

5) Ends: Beveled or square cut, plastic capped, painted.

6) Packing: bundles wrapped with strong steel strip, seaworthy packing.

4、Packaging & Delivery:

Packaging Details: | seaworthy package, bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Seamless Pipe:

①How is the quality of your products?

We have many years business experience in this area, and we have professional engineer and manager team and sure we can provide you high quality production and professional service.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

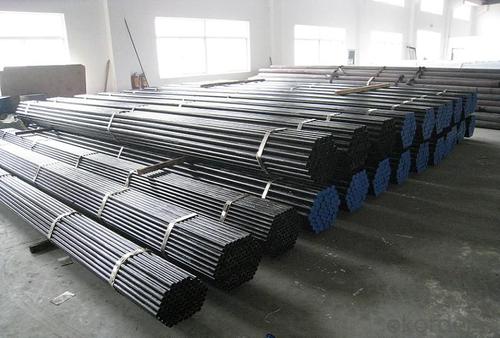

6、Seamless Pipe Images:

- Q: What are the different types of hangers used for supporting steel pipes?

- There are several different types of hangers used for supporting steel pipes, each with its own unique design and purpose. Some of the most common types include: 1. Clevis Hangers: These hangers consist of a U-shaped loop that is attached to a support structure using a threaded rod. The pipe is then placed inside the loop and secured in place with a bolt. Clevis hangers are often used in vertical pipe runs and provide excellent support and stability. 2. Split Ring Hangers: These hangers are designed with a split ring that wraps around the pipe and is attached to a support structure using a threaded rod. Split ring hangers allow for easy installation and adjustment, making them suitable for various pipe sizes and applications. 3. Pipe Clamps: Pipe clamps are simple and versatile hangers that consist of a metal clamp that wraps around the pipe and is secured to a support structure using screws or bolts. These hangers are available in various designs, such as one-hole, two-hole, or cushioned clamps, to accommodate different pipe sizes and provide stability. 4. Beam Clamps: Beam clamps are specifically designed to attach to overhead support beams or structures. They typically feature a clamp that wraps around the beam and a threaded rod or bolt that attaches to the pipe. Beam clamps are suitable for supporting horizontal pipe runs and are commonly used in industrial and commercial settings. 5. Roller Hangers: Roller hangers are used when there is a need for pipe movement due to thermal expansion or contraction. These hangers consist of a roller that allows the pipe to move freely while still providing support. Roller hangers are commonly used in long pipe runs or where there is a significant temperature variation. 6. Spring Hangers: Spring hangers are designed to support pipes and absorb vibrations or shocks. They consist of a spring element that is attached to a support structure and a rod or rod assembly that supports the pipe. Spring hangers are often used in applications where there is a need for noise reduction or to prevent damage caused by vibrations. These are just a few examples of the different types of hangers used for supporting steel pipes. The choice of hanger depends on factors such as pipe size, weight, location, and specific requirements of the installation. Consulting with a professional or engineer is recommended to ensure the appropriate hangers are selected for each specific application.

- Q: What are the different types of supports used for steel pipes in buildings?

- There are several different types of supports that are commonly used for steel pipes in buildings. 1. Pipe Hangers: These are specifically designed to support the weight of the pipe and are usually made of metal or plastic material. Pipe hangers are attached to the building structure and hold the pipe in place, preventing it from sagging or moving. 2. Pipe Clamps: These are used to secure the pipe to a wall or other structural element. Pipe clamps typically consist of a metal band that wraps around the pipe and is then secured to the structure with bolts or screws. They provide stability and prevent the pipe from shifting or vibrating. 3. Pipe Shoes: These are support devices that are installed underneath the pipe to distribute the weight evenly and provide additional support. Pipe shoes are typically made of metal or rubber and can be attached to the building structure or embedded in concrete foundations. 4. Pipe Guides: These are used to guide the movement of the pipe and prevent it from shifting or bending excessively. Pipe guides are usually made of metal or plastic and are installed at specific intervals along the length of the pipe. 5. Pipe Rollers: These are used to support horizontal pipes and allow for expansion and contraction due to temperature changes. Pipe rollers are typically made of metal and consist of a series of rollers that the pipe rests on. They allow the pipe to move freely without causing damage to the building structure. It is important to select the appropriate type of support based on the specific requirements of the steel pipe and the building structure. Properly supporting steel pipes in buildings ensures their stability, durability, and overall safety.

- Q: What is the outer diameter and wall thickness of the welded steel pipe of national standard DN250?

- DN250 is the nominal diameter, the outer diameter of the steel pipe is 273mm, the thickness is above 6.5mm.

- Q: How do you calculate the pipe flow velocity coefficient for steel pipes?

- The Manning's equation is employed to determine the flow velocity in open channels and pipes, taking into consideration the hydraulic radius, slope, and roughness coefficient of the pipe. By applying this equation, the pipe flow velocity coefficient for steel pipes can be calculated. To ascertain the pipe flow velocity coefficient for steel pipes, the following steps should be followed: 1. Calculate the hydraulic radius (R) of the steel pipe by dividing the cross-sectional area (A) of the pipe by the wetted perimeter (P). The formula to use is R = A/P. 2. Determine the slope (S) of the pipe, which is the change in elevation divided by the length of the pipe. Usually, it is expressed as a ratio or a percentage. 3. Obtain the roughness coefficient (n) of the steel pipe, representing the internal roughness of the pipe. This information can be found in literature or pipe manufacturer specifications, often given in terms of the Manning's roughness coefficient. 4. Insert the values of hydraulic radius (R), slope (S), and roughness coefficient (n) into the Manning's equation: V = (1/n) * R^(2/3) * S^(1/2) where V signifies the flow velocity. 5. Solve the equation for V to calculate the pipe flow velocity coefficient for steel pipes. It is crucial to note that the calculated velocity coefficient may differ depending on specific pipe dimensions, flow conditions, and other factors. Therefore, it is advisable to consult relevant engineering standards or seek guidance from a hydraulic engineer to ensure accurate and reliable calculations for specific applications.

- Q: What is the difference between steel pipe and tubing?

- Steel pipe and tubing are both used in various applications, but they have distinct differences. The primary difference between steel pipe and tubing lies in their shape and dimensions. Steel pipe is typically round in shape and has a hollow interior. It is manufactured in a variety of sizes and thicknesses to accommodate different pressure and temperature requirements. Steel pipe is commonly used in construction, plumbing, and oil and gas industries for conveying fluids or gases. On the other hand, steel tubing can come in various shapes, including round, square, and rectangular. Unlike steel pipe, tubing is often measured by its outside diameter and wall thickness. Steel tubing is commonly used in structural applications, such as building frames, automotive components, and machinery. Another difference between steel pipe and tubing is their manufacturing process. Steel pipe is typically made from solid steel billets that are heated and stretched to create a seamless or welded tube. Tubing, on the other hand, can be produced through various methods, including hot or cold rolling, welding, or extrusion. In terms of strength and durability, both steel pipe and tubing offer excellent qualities. However, the specific requirements of the application will determine which one is more suitable. Steel pipe is often chosen for high-pressure or high-temperature applications, while steel tubing is preferred for structural purposes or when a specific shape is required. In summary, the main difference between steel pipe and tubing lies in their shape, measurement methods, and manufacturing processes. While steel pipe is round and measured by its inside diameter, tubing can come in various shapes and is typically measured by its outside diameter. Both steel pipe and tubing are widely used in different industries, but the choice depends on the specific application and requirements.

- Q: What are the different coating options for steel pipes?

- Steel pipes have numerous coating options to choose from, each serving a specific purpose and offering unique advantages. Some common coating options for steel pipes include: 1. Fusion Bonded Epoxy (FBE) Coating: FBE coating is widely used across industries due to its exceptional corrosion resistance, impact resistance, and adhesion to the pipe surface. This coating is typically applied through a heat-induced chemical reaction, resulting in a durable and protective layer. 2. Polyethylene (PE) Coating: PE coating is commonly employed for underground steel pipes as it provides superior resistance against corrosion, abrasion, and chemicals. It is applied using extrusion techniques, forming a seamless layer that prevents moisture penetration. 3. Polyurethane (PU) Coating: PU coating is renowned for its outstanding resistance to abrasion, chemicals, and harsh environmental conditions. It is frequently used for steel pipes exposed to extreme temperatures or aggressive environments. Multiple layers of PU coating can be applied to enhance protection. 4. Coal Tar Enamel (CTE) Coating: CTE coating is a traditional choice for steel pipes requiring protection against corrosion. It is a thick, black coating that effectively resists water, soil, and atmospheric corrosion. This coating is typically applied using a hot-applied method. 5. Zinc Coating: Zinc coating, also known as galvanization, is a widely used protective coating for steel pipes. It involves applying a layer of zinc to create a barrier against corrosion. Zinc coating can be applied through hot-dip galvanization or electro-galvanization techniques. 6. Concrete Coating: Concrete coating is often utilized for steel pipes in underground or submerged applications. It provides a robust protective layer against corrosion, abrasion, and mechanical damage. Concrete coating is typically applied as a cement mortar or reinforced concrete layer. These options represent just a few of the available coatings for steel pipes. The selection of a coating depends on factors such as the intended application, environmental conditions, and desired durability. Choosing the appropriate coating is crucial to ensure the longevity and performance of steel pipes in various industries.

- Q: Are steel pipes suitable for hydronic heating systems?

- Yes, steel pipes are suitable for hydronic heating systems. Steel pipes are known for their durability and strength, making them a reliable choice for transporting hot water or steam in a hydronic heating system. They can withstand high temperatures and pressures, ensuring efficient heat transfer throughout the system. Additionally, steel pipes are resistant to corrosion, which is important in preventing leaks or damage to the pipes over time. However, it is essential to properly insulate steel pipes to minimize heat loss and improve energy efficiency in the hydronic heating system. Overall, steel pipes are a popular and suitable option for hydronic heating systems due to their reliability, durability, and ability to handle the demands of heating water or steam.

- Q: How are steel pipes used in the telecommunications infrastructure?

- Steel pipes are used in the telecommunications infrastructure for various purposes such as underground cable installation, mounting antennas, and supporting communication towers. They provide durability, strength, and protection for the cables and equipment, ensuring reliable and efficient communication networks.

- Q: What are the future trends in steel pipe manufacturing?

- Some future trends in steel pipe manufacturing include the adoption of advanced technologies such as automation and robotics, the development of high-performance and sustainable materials, the implementation of efficient and eco-friendly production processes, and the integration of digitalization and data analytics for improved quality control and supply chain management. Additionally, there is a growing focus on the development of specialized pipes for specific industries such as oil and gas, construction, and automotive, as well as an increased emphasis on product customization and tailored solutions to meet the evolving needs of customers.

- Q: How do steel pipes handle chemical substances?

- Steel pipes are highly resistant to chemical substances due to their high strength and corrosion-resistant properties. They can safely handle a wide range of chemical substances without undergoing any significant degradation or damage.

Send your message to us

ASTM API 5LCold Drawn Seamless Steel Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords