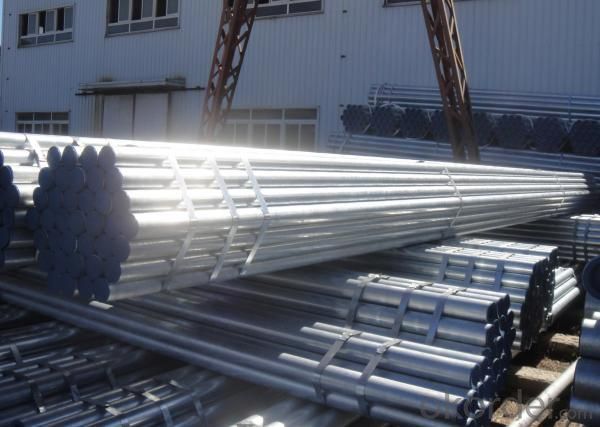

ASTM A53 Light Hot Dipped Galvanized Seamless and Welded Pipe

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1t m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application of ASTM A53 Light Hot Dipped Galvanized Seamless and Welded Pipe:

All the products supplied by us should be produced strictly according to the standards, such as ASTM A53, GB/T9711, API 5L, GB/3091, ASTM A500 and some other domestic and international standards to satisfy your various requirements, which is widely applied to the industries of construction, steel structure, natural gas, shipbuilding, chemical, boiler and other relative fields.

It is widely used in building, machine, chemical equipment, automobile industrial, container, it is also applied to agriculture and mine machine.

Standard:ASTM A53,BS1387,GB3091

Steel grade: ASTM A53: A, B, C GB3091, BS1387:Q195,Q215,Q235

Thickness of zinc coating: 100g/m2, 120g/m2, 150g/m2, 200g/m2, 250g/m2, 300g/m2, 350g/m2. 400g/m2

Size of ASTM A53 Light Hot Dipped Galvanized Seamless and Welded Pipe:

OD(MM)

WT(MM) |

21.3 |

26.7 |

33.4 |

42.2 |

48.3 |

60.3 |

73 |

88.9 |

114.3 |

141.3 |

168.3 |

219.1 |

1.70 |

|

|

|

|

|

|

|

|

|

|

|

|

1.80 |

|

|

|

|

|

|

|

|

|

|

|

|

1.90 |

|

|

|

|

|

|

|

|

|

|

|

|

2.00 |

|

|

|

|

|

|

|

|

|

|

|

|

2.10 |

|

|

|

|

|

|

|

|

|

|

|

|

2.20 |

|

|

|

|

|

|

|

|

|

|

|

|

2.30 |

|

|

|

|

|

|

|

|

|

|

|

|

2.40 |

|

|

|

|

|

|

|

|

|

|

|

|

2.50 |

|

|

|

|

|

|

|

|

|

|

|

|

2.75 |

|

|

|

|

|

|

|

|

|

|

|

|

3.00 |

|

|

|

|

|

|

|

|

|

|

|

|

3.25 |

|

|

|

|

|

|

|

|

|

|

|

|

3.50 |

|

|

|

|

|

|

|

|

|

|

|

|

3.75 |

|

|

|

|

|

|

|

|

|

|

|

|

4.00 |

|

|

|

|

|

|

|

|

|

|

|

|

4.25 |

|

|

|

|

|

|

|

|

|

|

|

|

4.50 |

|

|

|

|

|

|

|

|

|

|

|

|

4.75 |

|

|

|

|

|

|

|

|

|

|

|

|

5.00 |

|

|

|

|

|

|

|

|

|

|

|

|

5.25 |

|

|

|

|

|

|

|

|

|

|

|

|

ASTM A53

ASTM A53 LIGHT ( HOT DIPPED GALVANIZED PIPES) | ||||||||||||||||

SIZE |

Max |

Min |

Wall Thickness |

Bare Pipes Weight |

Screwed &

Socketed Pipes

Weight | |||||||||||

INCH |

NB(MM) |

mm |

mm |

mm |

kg/m |

kg/m | ||||||||||

1/2" |

15 |

21.4 |

21 |

2 |

0.947 |

0.956 | ||||||||||

3/4" |

20 |

26.9 |

26.4 |

2.3 |

1.38 |

1.39 | ||||||||||

1" |

25 |

33.8 |

33.2 |

2.6 |

1.98 |

2 | ||||||||||

1-1/4" |

32 |

42.5 |

41.9 |

2.6 |

2.54 |

2.57 | ||||||||||

1-1/2" |

40 |

48.4 |

47.8 |

2.9 |

3.23 |

3.27 | ||||||||||

2" |

50 |

60.2 |

59.6 |

2.9 |

4.08 |

4.15 | ||||||||||

2-1/2" |

65 |

76 |

75.2 |

3.2 |

5.71 |

5.83 | ||||||||||

3" |

80 |

88.7 |

87.9 |

3.2 |

6.72 |

6.39 | ||||||||||

3-1/2" |

90 |

113.9 |

113 |

3.6 |

9.75 |

10 | ||||||||||

ASTM A53 MEDIUME ( HOT DIPPED GALVANIZED PIPES) | ||||||||||||||||

SIZE |

Max |

Min |

Wall Thickness |

Bare Pipes Weight |

Screwed &

Socketed

Pipes Weight | |||||||||||

INCH |

NB(MM) |

mm |

mm |

mm |

kg/m |

kg/m | ||||||||||

1/2" |

15 |

21.7 |

21.1 |

2.6 |

1.21 |

1.22 | ||||||||||

3/4" |

20 |

27.2 |

26.6 |

2.6 |

1.54 |

1.57 | ||||||||||

1" |

25 |

34.2 |

33.4 |

3.2 |

2.41 |

2.43 | ||||||||||

1-1/4" |

32 |

42.9 |

42.1 |

3.2 |

3.1 |

3.13 | ||||||||||

1-1/2" |

40 |

48.9 |

48.3 |

3.2 |

3.57 |

3.61 | ||||||||||

2" |

50 |

60.8 |

59.9 |

3.6 |

5.03 |

5.1 | ||||||||||

2-1/2" |

65 |

76.6 |

75.4 |

3.6 |

5.43 |

6.55 | ||||||||||

3" |

80 |

89.5 |

88.1 |

4.5 |

8.37 |

8.54 | ||||||||||

4" |

100 |

114.9 |

113.3 |

4.5 |

12.2 |

12.5 | ||||||||||

5" |

125 |

140.6 |

138.7 |

5 |

15.6 |

17.1 | ||||||||||

6" |

150 |

166.1 |

164.1 |

5 |

19.7 |

20.3 | ||||||||||

ASTM A53 HEAVY ( HOT DIPPED GALVANIZED PIPES) | ||||||||||||||||

SIZE |

Max |

Min |

Wall Thickness |

Bare Pipes Weight |

Screwed &

Socketed

Pipes Weight | |||||||||||

INCH |

NB(MM) |

mm |

mm |

mm |

kg/m |

kg/m | ||||||||||

1/2" |

15 |

21.7 |

21.1 |

3.2 |

1.44 |

1.45 | ||||||||||

3/4" |

20 |

27.2 |

26.6 |

3.2 |

1.87 |

1.88 | ||||||||||

1" |

25 |

34.2 |

33.4 |

4 |

2.94 |

2.96 | ||||||||||

1-1/4" |

32 |

42.9 |

42.1 |

4 |

3.8 |

3.83 | ||||||||||

1-1/2" |

40 |

48.9 |

48.3 |

4 |

4.38 |

4.42 | ||||||||||

2" |

50 |

60.8 |

59.9 |

4.5 |

5.19 |

5.26 | ||||||||||

2-1/2" |

65 |

76.6 |

75.4 |

4.5 |

7.93 |

8.05 | ||||||||||

3" |

80 |

89.5 |

88.1 |

5 |

10.3 |

10.5 | ||||||||||

4" |

100 |

114.9 |

113.3 |

5.4 |

14.5 |

14.9 | ||||||||||

5" |

125 |

140.6 |

138.7 |

5.4 |

17.9 |

18.4 | ||||||||||

6" |

150 |

166.1 |

164.1 |

5.4 |

21.3 |

22.9 | ||||||||||

- Q: What is the average cost of steel pipes?

- The average cost of steel pipes can vary significantly depending on factors such as size, grade, and quantity needed. Therefore, it is difficult to provide a specific average cost without more information.

- Q: What is the difference between seamless steel pipes and seamless stainless steel pipes?

- The main difference between seamless steel pipes and seamless stainless steel pipes lies in their composition. Seamless steel pipes are typically made from carbon steel, which is an alloy of iron and carbon. On the other hand, seamless stainless steel pipes are made from an alloy of iron, carbon, and chromium, which gives them enhanced corrosion resistance and durability. This makes seamless stainless steel pipes suitable for applications where resistance to corrosion is essential, such as in the food industry or in environments with high humidity or exposure to chemicals.

- Q: What is the average lifespan of steel pipes?

- The average lifespan of steel pipes varies depending on various factors such as their quality, usage, and maintenance. However, under normal conditions, well-maintained steel pipes can last for several decades or even longer.

- Q: How are steel pipes inspected for defects?

- Steel pipes are typically inspected for defects using various non-destructive testing methods such as ultrasonic testing, magnetic particle inspection, and visual inspection. These techniques help identify any cracks, corrosion, or other defects in the pipes, ensuring their structural integrity and quality.

- Q: What is the difference between hot-dip galvanizing and electroplating for steel pipes?

- Hot-dip galvanizing and electroplating are two common methods used to provide corrosion protection for steel pipes, but there are key differences between the two processes. Hot-dip galvanizing involves immersing the steel pipes into a bath of molten zinc, which forms a metallurgical bond with the steel. This results in a thick and durable zinc coating that provides excellent corrosion resistance. The process of hot-dip galvanizing creates a uniform coating that covers the entire surface of the steel pipe, including both the external and internal surfaces. This makes hot-dip galvanizing particularly effective for protecting both the inside and outside of the pipes. On the other hand, electroplating is a process that involves the deposition of a thin layer of metal onto the surface of the steel pipes using an electric current. In the case of electroplating for steel pipes, typically a layer of zinc is applied. Unlike hot-dip galvanizing, electroplating does not provide a metallurgical bond between the zinc and the steel. Instead, it creates a mechanical bond, which is not as strong or durable as the bond formed through hot-dip galvanizing. The electroplated zinc layer is thinner compared to hot-dip galvanizing, which means it may not provide the same level of corrosion protection. Another difference between hot-dip galvanizing and electroplating is the application process. Hot-dip galvanizing requires immersing the steel pipes into a bath of molten zinc, which can be a time-consuming process. Electroplating, on the other hand, involves applying the zinc coating through an electrolytic cell, which can be faster and more efficient. In summary, the main difference between hot-dip galvanizing and electroplating for steel pipes lies in the thickness and durability of the coating, as well as the bonding mechanism between the zinc and the steel. Hot-dip galvanizing provides a thicker and more durable coating with a metallurgical bond, making it more effective for long-term corrosion protection. Electroplating, on the other hand, creates a thinner coating with a mechanical bond, which may be suitable for applications requiring a less robust level of corrosion resistance.

- Q: Are steel pipes suitable for desalination plants?

- Desalination plants can benefit greatly from the use of steel pipes. These pipes possess a variety of advantages that make them an ideal option for such facilities. Firstly, their resistance to corrosion is of utmost importance in desalination plants, where saltwater can be highly corrosive. The fact that steel pipes can withstand such corrosive conditions ensures the durability and longevity of the infrastructure, ultimately reducing maintenance and replacement expenses. Secondly, steel pipes exhibit remarkable strength, enabling them to withstand high-pressure situations commonly encountered in desalination plants. The ability of steel pipes to handle intense water flow without deformation or leakage guarantees the efficient and dependable operation of the desalination process. Moreover, steel pipes boast excellent heat resistance properties, rendering them suitable for desalination plants that engage in heat-intensive procedures like distillation or reverse osmosis. These pipes can endure high temperatures without suffering any structural damage, ensuring the secure and efficient transfer of heated water or steam. Furthermore, steel pipes are readily available and come in a wide range of sizes and specifications, allowing for flexibility in the design and construction of desalination plants. This availability and versatility make steel pipes a cost-effective choice for desalination projects. Overall, due to their resistance to corrosion, high strength, heat resistance, availability, and cost-effectiveness, steel pipes are highly suitable for desalination plants and are extensively used in the industry.

- Q: How are steel pipes tested for pressure and leakage?

- To ensure the safety and reliability of steel pipes, various methods are employed to test them for pressure and leakage. Hydrostatic testing is a commonly used technique, whereby the pipe is filled with water and subjected to a specific pressure for a set period of time. This examination aims to detect any weaknesses or leaks by observing if there is a drop in pressure or visible water leakage. The test carefully monitors and measures the pressure, and if the pipe successfully withstands the required pressure without any signs of leakage, it is deemed to have passed. In addition to hydrostatic testing, other non-destructive methods can also be utilized. Ultrasonic testing, for instance, employs high-frequency sound waves to identify flaws or defects in the pipe material. Similarly, magnetic particle testing involves the application of a magnetic field to the pipe and inspecting it for any magnetic particles that may indicate cracks or imperfections. Furthermore, visual inspection is a crucial component of the pressure and leakage testing of steel pipes. Trained inspectors thoroughly examine both the exterior and interior surfaces of the pipe to detect any visible signs of damage, such as corrosion, cracks, or faulty welds. This visual assessment aids in identifying potential weak points that may lead to leaks or failures under pressure. In summary, a comprehensive evaluation of steel pipes for pressure and leakage involves a combination of hydrostatic testing, non-destructive methods, and visual inspection. These rigorous procedures guarantee that the pipes meet the required standards and are safe for their intended applications.

- Q: What are the different methods of joining steel pipes without welding?

- There are several methods of joining steel pipes without welding, including: 1. Mechanical Couplings: These couplings consist of two separate pieces that are attached to the ends of the pipes and then tightened together. They provide a secure and leak-proof connection without the need for welding. 2. Threaded Connections: In this method, the ends of the steel pipes are threaded to create a male and female connection. The pipes are then screwed together using pipe threads, providing a strong and reliable joint. 3. Flanged Connections: Flanges are used to connect steel pipes by bolting them together. The flanges have a flat surface with holes that align with corresponding holes in the opposite flange. Bolts are then inserted and tightened to create a tight seal. 4. Grooved Connections: This method involves grooving the ends of the steel pipes and then using grooved couplings to join them. The couplings have teeth that interlock with the grooves, creating a secure and rigid connection. 5. Compression Fittings: Compression fittings are used to join steel pipes by compressing a metal or plastic ring onto the pipe's outer surface. This creates a tight seal and a reliable connection, without the need for welding. 6. Adhesive Bonding: Special adhesives designed for metal bonding can be used to join steel pipes. The adhesive is applied to the surfaces of the pipes, which are then pressed together and left to cure, creating a strong and durable bond. 7. Clamping: Clamps can be used to hold steel pipes together, creating a temporary connection. This method is commonly used for testing purposes or in situations where the pipes need to be easily disassembled. Each of these methods has its own advantages and limitations, and the choice depends on factors such as the specific application, pipe material, and the required strength of the joint.

- Q: What is the difference between steel pipes and ductile iron pipes?

- Steel pipes and ductile iron pipes are both commonly used for conveying fluids and gases, but they have notable differences. The main distinction lies in their composition and properties. Steel pipes are made of an alloy of iron and carbon, providing them with high strength and durability. On the other hand, ductile iron pipes are composed of iron, carbon, and small amounts of other elements such as silicon and manganese, which make them more flexible and resistant to bending. Ductile iron pipes also have superior corrosion resistance compared to steel pipes. Overall, steel pipes are preferred for applications requiring higher strength and pressure resistance, while ductile iron pipes are often chosen for their flexibility and corrosion resistance.

- Q: What are the different types of steel pipes?

- There are several different types of steel pipes, including seamless steel pipes, welded steel pipes, galvanized steel pipes, and stainless steel pipes.

1. Manufacturer Overview

| Location | Tianjin, China |

| Year Established | 1999 |

| Annual Output Value | Above Thirty Million RMB |

| Main Markets | Main land; Middle East; Southeast Asia |

| Company Certifications | ISO 9001:2011;CE:2010 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin |

| Export Percentage | 30% - 40% |

| No.of Employees in Trade Department | 101-200 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | 50,000 square meters |

| No. of Production Lines | Above 14 |

| Contract Manufacturing | Hui Ke Steel Pipe Co,.Ltd |

| Product Price Range | Average |

Send your message to us

ASTM A53 Light Hot Dipped Galvanized Seamless and Welded Pipe

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1t m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords