ASTM A 53 Pre-Galvanized Steel Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

- Q: How are steel pipes insulated to prevent noise transmission?

- Steel pipes are typically insulated to prevent noise transmission through the use of materials such as mineral wool, fiberglass, or foam. These insulation materials are wrapped around the pipes to create a barrier that absorbs and reduces sound waves, preventing them from traveling and causing noise transmission.

- Q: What are the common applications of galvanized steel pipes?

- Galvanized steel pipes are commonly used in various industries and applications such as plumbing, water supply systems, gas pipelines, electrical conduits, construction projects, fencing, and outdoor structures. The galvanization process adds a protective zinc coating to the steel, making it resistant to corrosion and extending its lifespan, making it ideal for applications requiring durability and longevity.

- Q: How are steel pipes used in the construction of buildings?

- Steel pipes are commonly used in the construction of buildings for various purposes such as structural support, plumbing, and electrical installations. They provide strength and durability, allowing for the construction of high-rise buildings and large-scale structures. Steel pipes are used to create the framework of the building, forming the skeleton that supports the weight and load of the structure. Additionally, steel pipes are used for plumbing systems, effectively transporting water and sewage throughout the building. They are also used for electrical installations, providing a safe and efficient conduit for wiring. Overall, steel pipes play a crucial role in the construction of buildings, ensuring stability, functionality, and longevity.

- Q: What are the different methods of inspecting steel pipes?

- There are several methods of inspecting steel pipes, including visual inspection, non-destructive testing (such as ultrasonic testing, magnetic particle testing, and dye penetrant testing), radiographic testing, and eddy current testing. These methods help identify any defects, such as cracks, corrosion, or wall thickness variations, ensuring the quality and integrity of the steel pipes.

- Q: How are steel pipes used in the manufacturing of marine applications?

- Steel pipes are commonly used in the manufacturing of marine applications due to their durability, strength, and resistance to corrosion. They play a crucial role in various applications such as shipbuilding, offshore platforms, and underwater pipelines. Steel pipes are used to transport fluids, gases, and oils, as well as for structural support and protection against harsh marine environments. Additionally, steel pipes are also utilized in the construction of marine heat exchangers and cooling systems.

- Q: What are the different types of steel pipe supports for offshore platforms?

- There are several different types of steel pipe supports used for offshore platforms, including pipe racks, pipe clamps, pipe hangers, and pipe saddles. Pipe racks are used to support multiple pipes and provide a structure for them to rest on. Pipe clamps are used to secure individual pipes to structures or walls. Pipe hangers are used to suspend pipes from overhead structures, while pipe saddles are used to support pipes on horizontal surfaces. These different types of supports are designed to ensure the stability and integrity of the pipes in offshore environments.

- Q: How are steel pipes used in the construction of biomass power plants?

- Steel pipes are used in biomass power plants for various applications such as transporting biomass fuel, carrying water for steam generation, and distributing hot water or steam throughout the plant. They provide a sturdy and reliable infrastructure for the efficient functioning of the plant, ensuring the safe and effective operation of the biomass power generation process.

- Q: What are the different testing methods used for steel pipes?

- To ensure the quality and reliability of steel pipes, various testing methods are employed. These methods include: 1. Non-destructive Testing (NDT): Ultrasonic testing, magnetic particle inspection, and liquid penetrant testing are utilized in NDT to identify surface or subsurface defects in steel pipes without causing any damage. 2. Mechanical Testing: Mechanical testing encompasses various tests to evaluate the mechanical properties of steel pipes, such as tensile strength, yield strength, elongation, hardness, and impact resistance. These tests determine the structural integrity and performance of the pipes. 3. Hydrostatic Testing: This method involves subjecting steel pipes to high-pressure water to assess their ability to withstand expected operating conditions. The pipes are filled with water and pressurized to a predetermined level for a specified duration. Any leaks or deformations are detected during this test. 4. Dimensional Inspection: This testing method ensures that steel pipes meet specified dimensional requirements. It involves measuring critical dimensions such as diameter, wall thickness, and length to verify compliance with applicable standards. 5. Visual Inspection: Trained inspectors visually assess the external appearance of steel pipes using this basic method. They examine the pipes for surface defects such as cracks, corrosion, or irregularities in shape or finish. 6. Chemical Analysis: Chemical analysis is conducted to determine the composition and elemental content of steel pipes. It ensures that the pipes are made from the correct grade of steel and meet required chemical composition standards. 7. Metallographic Examination: Metallography involves examining the microstructure of steel pipes under a microscope to evaluate their quality and integrity. It helps identify internal defects like grain boundaries, inclusions, or improper heat treatment that may impact overall performance. By employing these testing methods, manufacturers and inspectors can guarantee that steel pipes meet necessary quality standards and are suitable for their intended applications.

- Q: Is there any difference between HFW steel pipe and ERW steel pipe?

- High frequency welding uses the skin effect to concentrate the energy of the high frequency current on the surface of the workpiece, and uses the proximity effect to control the position and range of the high frequency current flow path. The speed of the current is very fast, it can in a short period of time will be adjacent to the edge of the steel plate heating, melting, and through the extrusion docking, each has its own advantages, but also each has its own shortcomings. Generally according to specific circumstances, specific analysis of specific choices.

- Q: How are steel pipes connected in pipeline construction?

- Steel pipes are connected in pipeline construction through various methods such as welding, threading, and flanging. Welding involves joining the pipes using heat and fusion, creating a strong and durable connection. Threading involves screwing two pipes together using threads on the ends of the pipes. Flanging involves connecting the pipes by bolting together flanges on the ends of each pipe. These connection methods ensure a secure and leak-proof pipeline system.

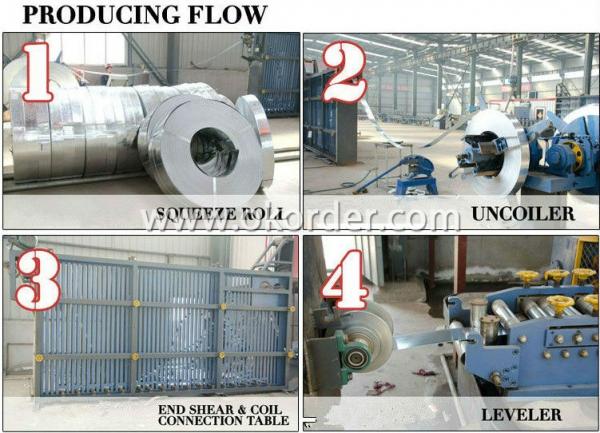

The main production and sale of galvanized steel, the thin-walled high-frequency welded pipe, galvanized pipe, square pipe, rectangular pipe, conduit, EMT conduit, greenhouse pipes, galvanized pipes, and other related products, annual production capacity of 40,000 tons. The company has independent export rights.

1. Manufacturer Overview

| Location | Tianjin ,China |

| Year Established | 2004 |

| Annual Output Value | Above 100milion rmb |

| Main Markets | Main land;Middle East;Southeast Asia |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | 38000squar meter |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

ASTM A 53 Pre-Galvanized Steel Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50MT m.t.

- Supply Capability:

- 5000 Tons Per Month m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords