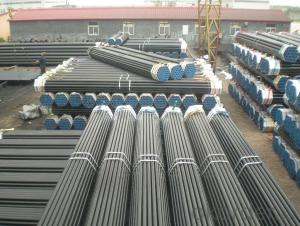

API GRADE CARBON STEEL SEAMLESS PIPES WITH FACTORY PRICE

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Quick Details

Thickness: | 2.0 - 85 mm | Section Shape: | Round | Outer Diameter: | 17 - 914.4 mm |

Secondary Or Not: | Non-secondary | Application: | Oil Pipe | ||

Technique: | Hot Rolled | Certification: | API | Surface Treatment: | VARNISH PAITING |

Special Pipe: | API Pipe | Alloy Or Not: | Non-alloy | END: | PLAIN,BEVELED OR THREADED |

OKorder is offering high quality Seamless Steel Alloy Pipe at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel pipe, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Seamless Steel Alloy Pipe is ideal for long distance oil, gas, and natural gas pipelines on land and offshore. They can also be applied in construction projects, offshore platforms, power stations, the petrochemical industry and municipal construction.

Product Advantages:

OKorder's Steel Pipe is durable, resists corrosion and is recyclable.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Professional Service

· Competitive pricing

Product Pictures:

- Q: How do you calculate the pipe friction loss for steel pipes?

- In order to determine the pipe friction loss for steel pipes, one must utilize the Darcy-Weisbach equation. This particular equation is widely employed in the field of fluid dynamics to ascertain the drop in pressure or friction loss that arises from the flow of fluid through a pipe. The equation is formulated as follows: The pressure drop or friction loss (ΔP) can be calculated by dividing the product of the Darcy friction factor (f), the length of the pipe (L), the density of the fluid (ρ), and the square of the velocity of the fluid (V²), by twice the diameter of the pipe (D). The Darcy friction factor (f), which is a dimensionless value, is contingent upon the Reynolds number (Re) and the relative roughness (ε/D) of the pipe. Here, ε represents the absolute roughness of the pipe. There are various correlations or Moody's diagram that can be employed to determine the friction factor. Once the friction factor has been ascertained, the values for length, density, velocity, and diameter can be substituted into the equation to calculate the pressure drop or friction loss. It is of utmost importance to ensure that the units for all variables remain consistent (e.g., length in meters, density in kg/m³, velocity in m/s, diameter in meters) in order to achieve precise results. By utilizing this equation and acquiring the requisite parameters, it becomes possible to calculate the pipe friction loss for steel pipes. Such calculations are essential in the design and analysis of fluid flow systems.

- Q: Can steel pipes be used for conveying compressed air?

- Yes, steel pipes can be used for conveying compressed air. Steel pipes are commonly used in applications where high pressure and durability are required, such as in industrial settings. Steel pipes have a high tensile strength and can withstand the high pressures generated by compressed air systems. Additionally, steel pipes are resistant to corrosion, which is important when dealing with moisture in compressed air. However, it is important to ensure that the steel pipes are properly sized and rated for the specific pressure and flow requirements of the compressed air system. Additionally, proper installation and maintenance practices should be followed to prevent any potential leaks or failures.

- Q: How long is the seamless tube?

- Welded pipe is generally 6912 meters fixed length, seamless pipe on the market in general non fixed foot, but usually more than 6 meters

- Q: What are the advantages of using steel pipes in the manufacturing of storage tanks?

- There are several advantages of using steel pipes in the manufacturing of storage tanks. Firstly, steel pipes are highly durable and have a long lifespan, making them capable of withstanding high pressure and harsh environmental conditions. Secondly, steel pipes offer excellent resistance to corrosion, ensuring the integrity of the storage tank and preventing any leakage or contamination. Additionally, steel pipes are flexible and can be easily fabricated into various shapes and sizes, allowing for customization based on specific storage requirements. Lastly, steel pipes are cost-effective and readily available, making them a popular choice in the manufacturing industry.

- Q: Difference between seamless steel pipe and welded pipe

- Seamless steel pipe can be used in various industries, such as liquid, pneumatic, pipeline and gas pipeline.

- Q: What are the dimensions of a standard steel pipe?

- The dimensions of a standard steel pipe can vary depending on its intended use, but common dimensions include a nominal size (such as 1/2 inch, 1 inch, 2 inches, etc.) and a schedule number indicating its wall thickness (such as Schedule 40 or Schedule 80). The outside diameter of the pipe can range from small sizes of less than half an inch to large sizes of several feet. The length of a standard steel pipe is typically 21 feet, although shorter lengths are also available.

- Q: How are steel pipes measured and sized?

- Steel pipes are measured and sized based on their outer diameter (OD) and wall thickness. The OD is the measurement of the outer circumference of the pipe, while the wall thickness refers to the thickness of the pipe's walls. These two measurements are essential in determining the size of steel pipes, which are commonly categorized using nominal pipe size (NPS) or nominal diameter (DN). NPS is a North American standard, while DN is an international standard. The sizing process ensures uniformity and facilitates compatibility with fittings and other pipeline components.

- Q: How do you calculate the pipe flow rate coefficient for steel pipes?

- In order to determine the pipe flow rate coefficient for steel pipes, one must consider several factors pertaining to the pipe's dimensions, material properties, and the fluid that is flowing through it. The pipe flow rate coefficient, which is also known as the discharge coefficient (Cd), is a dimensionless quantity that represents the efficiency of the fluid flow within the pipe. To calculate the pipe flow rate coefficient for steel pipes, the following steps should be followed: 1. Find the inside diameter (ID) of the steel pipe. This measurement corresponds to the internal cross-sectional area of the pipe through which the fluid passes. 2. Use the formula A = π * (ID/2)^2 to calculate the pipe's cross-sectional area (A). Here, π represents the mathematical constant pi (approximately 3.14). 3. Measure the pressure drop (∆P) across the steel pipe. This refers to the difference in pressure between the inlet and outlet of the pipe. 4. Measure the fluid flow rate (Q) through the pipe. This can be achieved by using flow meters or by determining the time it takes for a known volume of fluid to traverse the pipe. 5. Utilize the formula V = Q / A to calculate the velocity (V) of the fluid flowing through the pipe. In this equation, Q represents the fluid flow rate and A denotes the cross-sectional area of the pipe. 6. Employ the formula Cd = Q / (A * √(2 * ∆P / ρ)) to calculate the pipe flow rate coefficient (Cd). In this formula, ρ represents the fluid density. The equation is derived from Bernoulli's equation and incorporates the pressure drop, fluid flow rate, and fluid density. It is important to note that the pipe flow rate coefficient for steel pipes can vary depending on factors such as pipe roughness, fluid viscosity, and Reynolds number. Therefore, it is advisable to consult relevant engineering standards, such as the Darcy-Weisbach equation or the Hazen-Williams equation, to obtain more accurate values for specific pipe configurations and fluid properties.

- Q: What are the different types of steel pipe coatings for corrosion protection?

- Some of the different types of steel pipe coatings for corrosion protection include epoxy coatings, polyethylene coatings, polyurethane coatings, and zinc coatings.

- Q: How are steel pipes coated for underground applications?

- Steel pipes for underground applications are typically coated using a process called fusion bonded epoxy (FBE) coating. This involves applying a special epoxy powder coating to the surface of the steel pipe and then heating it to fuse the coating into a smooth and durable finish. The FBE coating provides excellent corrosion resistance and protects the steel pipe from the harsh underground environment.

Send your message to us

API GRADE CARBON STEEL SEAMLESS PIPES WITH FACTORY PRICE

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords