Antiflaming,fire-resistance rubber hose assembly ISO9001:2008

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

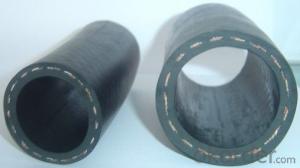

Antiflaming,fire-resistance rubber hose assembly

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

· Model Number: GB/T3683-92

Packaging & Delivery

Packaging Details: | hydraulic hose is wrapped with fabrics |

Delivery Detail: | 80000meters/30days |

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer and laye

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelts,and chemical industry

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

- Q: What do you mean by "DN" on hydraulic hose?

- Hydraulic hose temperature: -40 ~ 120 DEG C, product specification range: DN2.5mm ~ DN305mm.

- Q: How far is the gas cooker from the gas riser in the kitchen?

- Rubber pipes shall not be worn through the chamber and should be checked regularly. It is found that aging and damage should be replaced in a timely manner (rubber tubes shall be used for a period of not more than 18 months).

- Q: There are several ways to connect the built-in rubber stop

- The spot heat vulcanization method is a heat vulcanizing mould matched with a water stopping strip and a raw film vulcanizing heat junction. The construction is difficult, but the joint effect is ideal, which is suitable for the project with strict quality requirements.

- Q: The engine cylinder head cover behind the drop rubber tube what reason (Xichai 490 engine) (note the valve chamber cover tube)

- You don't know how to repair the craft, experienced by the feeling on the line, strictly speaking, is the valve clearance feeler to grasp, generally 125, 150 valve clearance at around 0.025-0.030, the exhaust valve to the inlet valve a little bigger than. Your car is too loud. Do you think the cam or valve is too big to wear? You have to go to an experienced garage to repair it.

- Q: What is the maximum pressure that a hose can bear?

- Of course, there is a super high-pressure hydraulic hose, the working pressure of up to 80MP., using 6 layers of steel wire or more winding process.

- Q: The copper joint is leaking, and the tap water hose and copper joint are leaking

- Because the water has temperature, and the thermal expansion coefficient of aluminum and copper is different,The coefficient of thermal expansion is different, that is to say, the interface is always moving (heat up, cold contraction),

- Q: Diameter 127mm steel pipe, and diameter 127mm rubber hose how to connect?

- A metal ring is sheathed inside the rubber tube, and the rubber tube with the metal ring is sheathed into the metal tube so that they can come into close contact with each other. In brief, the metal collar and the steel pipe hold the rubber tube in the center. I wonder if you understand. The outer diameter of the metal ring is about 111~119mm. It's hard to say how specific it is.

- Q: What does rubber soft joint "KDTF" mean?

- It is a kind of pipe joint with high elasticity, high air tightness, medium resistance and weather resistance. The main outer layer, inner layer, intermediate layer reinforced polyester cord fabric, steel wire pressure protection layer.

- Q: How to distinguish the true and false corrosion resistant rubber soft joint?

- Put the rubber joint in the corrosive liquid which needs to pass. One day, 24h can see that the swelling ratio is not more than 5%!

- Q: Must the hose for the cooker be made of oil resistant rubber hoses?

- When the gas combustion equipment and gas pipeline for hose connection, the design should meet the following requirements: (1) the burner of household gas stove and laboratory use, the connecting hose length should not exceed 2m, have no interface; (2) industrial production with mobile gas burning equipment, the connecting hose the length should not exceed 30m, the interface should not exceed 2;...

Send your message to us

Antiflaming,fire-resistance rubber hose assembly ISO9001:2008

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords