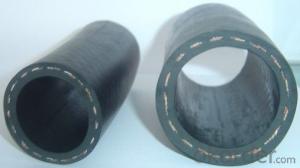

Antiflaming,fire-resistance rubber hose assembly 13-51mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Antiflaming,fire-resistance rubber hose assembly

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

· Model Number: GB/T3683-92

Packaging & Delivery

Packaging Details: | hydraulic hose is wrapped with fabrics |

Delivery Detail: | 80000meters/30days |

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer and laye

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelts,and chemical industry

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

- Q: Rubber soft joint, what brand of good, the best price is more reasonable. Don't say anything expensive.

- The rubber joints produced throughout the country have the longest history in Shanghai, and have the characteristics of the type and sales volume of Gongyi city. They have been sold in the plumbing market all over the country

- Q: What are the production processes and characteristics of high pressure rubber hose?

- According to the knitting process, the high-pressure hose is divided into high-pressure steel wire braided hose and high-pressure steel wire winding hose.

- Q: The basic buret is a rubber tube is inlaid with a glass bead to replace glass piston. Why this burets cannot be used to install Potassium Permanganate solution?

- Are made of glass, acid burette glass piston burette, no piston, just at the tip of a rubber tube, rubber tube with glass beads, glass or the lower beak. Why not the same because of acid burette, glass and alkali reaction, generate silicate, sticky, if it is very easy to use acid burette, the hole is blocked, damaged burets.

- Q: Three yuan ethylene propylene rubber hose, hydraulic oil and oil?

- First of all, three yuan ethylene propylene rubber is non-polar, oil is non-polar, as for hydraulic oil well, there are many kinds of polar hydraulic oil and non-polar hydraulic oil.

- Q: The rubber is sheathed on a metal cylinder. How should they be connected?

- With the combination of metal rubber is coated with adhesive before production and rubber vulcanization shaping, you can use this temporary experiment 502 geliahao for glue or adhesive, but the disadvantages of this thing with winter is not strong, the metal surface must be clean

- Q: What is the essential difference between rubber expansion joint and rubber joint?

- A rubber joint is a hollow rubber product used for flexible connections between metal pipes. The flexible joint is also called soft rubber pipe joints, rubber joints, soft rubber joints, flexible joints, high-pressure rubber joints, rubber shock absorber etc.. It is divided into 3 kinds: flange type, fixed flange type and thread type by connection. The structure can be divided into single sphere, double sphere and curved sphere. A tubular rubber component is composed of inner and outer layers of rubber, cord and steel ring, which is vulcanized and molded and then combined with a metal flange or a parallel joint. This product can reduce vibration and noise, and can be compensated by thermal expansion and cold contraction due to temperature changes. It is widely used in various piping systems.

- Q: Is it feasible to use rubber material, middle canvas layer and outer rubber material in PVC rubber tube?

- Improvement measures: 1, adjust the process, plastic material in place; mixing rubber plastic stability; vulcanized rubbing with low temperature long time vulcanization; 2, test cloth in curing temperature shrinkage coefficient is too big, consider changing cloth;

- Q: What are the methods of sterilizing rubber hoses and Perspex?

- Our laboratory rubber tube is directly into the steam sterilizer. After a few cracks, throw them away and use the new ones. Plexiglass products, we are placed on super clean bench, UV irradiation above 30min. Sometimes it takes time to wipe with 60% alcohol cotton ball.

- Q: The gas water heater uses metal pipes and rubber pipes

- Rubber tube will be aging for long time, it is better to use gas special stainless steel bellows

- Q: What is the high and low pressure circuit of diesel engine?

- Low pressure oil circuit is the oil circuit from the tank to the diesel pump. The negative pressure is in the oil circuit, and the oil is drawn out with the diesel oil pump and is sucked into the diesel pump to pressurize. It's obvious that all the oil lines are rubber lines.

Send your message to us

Antiflaming,fire-resistance rubber hose assembly 13-51mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords