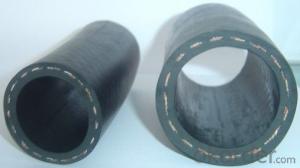

hydraulic hose , skin coated refractory coating layer, 13-51mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Antiflaming,fire-resistance rubber hose assembly

Specifications

High pressure hose to the winding wire matrix, skin coated refractory coating layer steel braided flame retardant layer and laye

APPLICATIONS:It is mainly used in high temperature surroundings and in conditions having heat source or heat radiation source,such as oil field well-control,metal smelts,and chemical industry

Inner Diameter of Hose mm | Inside Diameter | Reinforcement Diameter (mm) | Outside Diameter (mm) | Work Pressure (MPa) | Proof Pressure (MPa) | Minimum Explosive Pressure (MPa) | Minimum Bending Radius mm | Refractory °C | |||

Mpa | Psi | MPa | Psi | Mpa | Psi | ||||||

φ13(1/2") | 13±0.5 | 22.2±0.8 | 44±1.06 | 43 | 6230 | 64.5 | 9435 | 86 | 12460 | 230 | 750 |

φ16(5/8") | 16±0.5 | 26±0.8 | 47±1.5 | 38 | 5506 | 57 | 8259 | 76 | 11012 | 260 | 750 |

φ19(3/4") | 19±0.5 | 30±0.8 | 52±1.5 | 34.5 | 4999 | 51.75 | 7498 | 69 | 9998 | 300 | 750 |

φ25(1") | 25±0.8 | 36±0.8 | 59±1.5 | 27.5 | 3984 | 41.25 | 5976 | 55 | 7968 | 360 | 750 |

φ32(5/4") | 32±0.8 | 44±0.8 | 69±2.0 | 20.5 | 2970 | 30.75 | 4455 | 41 | 5940 | 470 | 750 |

φ38(3/2") | 38±1.0 | 76±2.0 | 87.2±5.1 | 17 | 2463 | 25.5 | 3694 | 34 | 4926 | 570 | 750 |

φ51(2") | 51±1.0 | 91±2.0 | 100.7±5.1 | 17 | 2463 | 25.5 | 3695 | 34 | 4926 | 740 | 750 |

hydraulic hose Universal Wire-braided DN6

Quick Details

· Place of Origin: Hebei, China (Mainland)

· Brand Name: CMAX/CNBM

· Model Number: GB/T3683-92

Packaging & Delivery

Packaging Details: | hydraulic hose is wrapped with fabrics |

Delivery Detail: | 80000meters/30days |

Specifications

Universal Wire-braided Hydraulic Hose, Q/FLT01-AStandard GB/T3683-92, Temperature range: -40 to +100

Universal Wire-braided Hydraulic Hose

Q/FLT01-AStandard GB/T3683-92

Tube: oil resistant synthetic rubber

Reinforcement: 1 W/B (one high tensile steel wire braid)

Cover: abrasion and weather resistant synthetic rubber

Temperature range: -40 to +100.

- Q: Why does Br2 corrode rubber tubes?

- Br2 bromine gasBr2 bromine element at room temperature is dark brown liquid, soluble in water, 100g water can dissolve about 3G bromine. Highly volatile, toxic, steam strongly stimulate the eyes, mucous membranes and so on. The water solution is called bromine.

- Q: Method for inserting glass tube into rubber tube when assembling instrument

- In the pipeline connection, the rubber tube and the plastic pipe are commonly used for the glass tube sleeve connection. Because the caliber of the glass tube is different, the sleeve connection method is different.The connection of the glass with the outer diameter can be connected by a rubber tube, and the inner diameter of the rubber tube shall be slightly smaller than the outer diameter of the glass tube, and the glass tube can be lubricated with water or soap (not oily lubricant) when connected.

- Q: The basic buret is a rubber tube is inlaid with a glass bead to replace glass piston. Why this burets cannot be used to install Potassium Permanganate solution?

- Are made of glass, acid burette glass piston burette, no piston, just at the tip of a rubber tube, rubber tube with glass beads, glass or the lower beak. Why not the same because of acid burette, glass and alkali reaction, generate silicate, sticky, if it is very easy to use acid burette, the hole is blocked, damaged burets.

- Q: Does rubber hose drink from tap water? Is it poisonous?

- .PVC is actually a vinyl polymerization substance, whose material is a non crystalline material. PVC materials often use stabilizers, lubricants, auxiliary processing agents, pigments, anti shock agents and other additives in practical use. Is not flammable, high strength, excellent resistance to climate variability and geometric stability. PVC has strong resistance to oxidizing agents, reducing agents and strong acids. However, it can be corroded by concentrated oxidizing acids such as concentrated sulfuric acid and concentrated nitric acid, and it is also not suitable for contact with aromatic hydrocarbons and chlorinated hydrocarbons. In addition, the terms person, vs, computer, abbreviated as PVC, and the PVC humanoid are often referred to as PVC.

- Q: Is it feasible to use rubber material, middle canvas layer and outer rubber material in PVC rubber tube?

- Improvement measures: 1, adjust the process, plastic material in place; mixing rubber plastic stability; vulcanized rubbing with low temperature long time vulcanization; 2, test cloth in curing temperature shrinkage coefficient is too big, consider changing cloth;

- Q: Is the rubber pipe joint installed in the middle of the pipe and pump for shock absorption?

- Control the noise produced by parts of machinery, equipment, and equipment. The pump foundation of the new pump house should adopt heavy weight to prevent vibration from producing noise. Vibration isolation should be set up with rubber vibration isolating pads to reduce vibration noise. Each pump unit shall be provided with a foundation to prevent resonance. Use "soft" connection as far as possible in the suction pipe and pressure pipe of the pump. Periodic maintenance problems, such as packing leakage, equipment parts loose, serious wear and tear of equipment parts, mechanical vibration and so on, should be repaired in time, thereby reducing noise.

- Q: Why are the lengths of the household combustion equipment linked to the gas pipe hose no more than 2 meters?

- A pipe is a weak link. Many accidents occur on pipes. In theory, the leakage of pipe per unit length may be the same. Then, the longer the pipe, the higher the risk coefficient.In reality, the longer the tube, the higher the possibility of being clipped. For example, bending, stretching, foot work, cracking, aging, these are potentially dangerous.

- Q: How to replace natural gas hose? Steps?

- Replace the natural gas hose first pressure relief, and resolutely put an end to the operation with pressure;According to the connection way of the hose, if it is O ring sealed, just tighten it directly;If it is cone thread, it can be wrapped with raw material tape or sealant.

- Q: Is rubber tube harmful to drinking water?

- There are drinking water standard rubber tube, ordinary hose can not be directly applied to drinking water, there is low toxicity!

- Q: What kind of material does hose screw protection cover have? What are their advantages and disadvantages?

- Hose cover is usually made of nylon or polyethylene

Send your message to us

hydraulic hose , skin coated refractory coating layer, 13-51mm

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords