Anticorrosive Best Quality Deep Carbonized Birch Wood

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1x20' FCL m.t.

- Supply Capability:

- 1500 CBM m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of the Best Quality Deep Carbonized Birch Wood

|

Species |

Birch |

|

Size |

Be customized as per request |

|

Treatment |

Deep carbonized |

|

Moisture content |

5--12% |

|

Usage |

most outdoor using |

|

Grade |

A Grade |

|

package |

Standard exporting package |

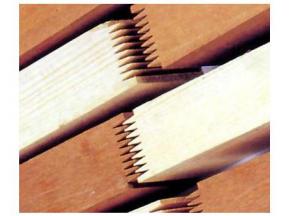

Features and Advantages of the Best Quality Deep Carbonized Birch Wood

1. Deep Carbonized Birch is very suitable for outdoor using

2. Waterproof, Sun-proof, Rot-proof, Fungi-proof

3. The size and the color can be customized according to your request

4. Treated by deep carbonized

5. Eco-friendly, no harm to the air, the plants, the humans

6. Are able to make the timber from the damage of the insects

7. Advanced flame retardent techinics

High quality and great service of the Best Quality Deep Carbonized Birch Wood

Our company is professtional in this products, we have professional team to ensure the quality of

the products and the exact shipping date of the order.

The usage and characteristics of the Best Quality Deep Carbonized Birch Wood

The deep carbonized birch is the good materials to make outdoor flooring, fence, wood

house, outdoor furniture ,sauna room and bathroom etc. At present, it's the most enviromental

antiseptic lotion in the world. The wood products treated with deep carbonized is durable and

prolonging the life of usage. Carbonized wood is with the deep wood grain, dark color and

wood fragrance.

Packing and Delivery of the Best Quality Deep Carbonized Birch Wood

Packing : standard exporting packing

Delivery: standard shipping time based on the country

The following pictures are for reference.

- Q: Can rust-proof wood be used in interior decoration? How about environmental protection? Is it toxic?

- 2, composite wood flooring (also known as strengthening the floor): stain resistance, acid loss is good, maintenance-free, flexible, non-slip performance, wear, antibacterial, not moth, mildew, good dimensional stability, Will be affected by temperature, moisture deformation, noise noise reduction, foot comfort, color, rich patterns, fully meet the individual design needs, fire performance B1 level, light weight, reduce the load of the building 3, cork flooring: wear resistance is poor, not easy to clean, feet soft and comfortable, non-slip performance, able to absorb noise, high prices It is recommended to choose composite wood flooring

- Q: What are the benefits of antiseptic wood huts?

- Anticorrosion huts economy, people have a feeling of return to nature, in Europe and the United States people choose the house will first choose anti-corrosion huts, anti-corrosion huts with Dongnuanxialiang, low cost, short construction period and other advantages. Antistatic wood huts with superior thermal insulation. Wood is a porous material, thermal conductivity is small, low thermal conductivity. Whether it is winter heating, or summer cooling, anti-corrosion wood house heat consumption is only brick 1/5. Antiseptic wood house insulation effect is 8 to 12 times the concrete, the noise reduction effect is four times the concrete.

- Q: Antiseptic wood under what circumstances deformation

- The deformation of the wood is caused by internal pressure, and the cracking of the wood is due to the new changes in the surface of the wood, but the fundamental reason for the change is that the moisture content within the wood has changed.

- Q: What is the difference between preservative wood and charcoal wood?

- Antiseptic wood, is the wood after a special anti-corrosion treatment, with rotten decay to prevent decay function, bio-invasive function of the wood, it is mainly used for outdoor or balcony terrace and the like.

- Q: Guangzhou antiseptic wood dealers are the most concentrated which building materials market

- but more estimates is the Shanghai Jiujia building materials market, is the largest building materials market in East China. Should be more than other building materials market operators in Guangzhou anti-corrosion wood dealers.

- Q: Wooden plastic outdoor flooring and antiseptic wood is the same thing

- No, wood is made of wood powder mixed with plastic powder made of wood, wood is treated after the treatment of wood.

- Q: Is carbonized wood better than antiseptic wood?

- Antiseptic wood is good, the following I will introduce the anti-corrosion wood: Antiseptic wood is made of wood preservatives with wood after the use of preservatives to prevent the decay of wood decaying wood. The main preservatives are CCA / ACQ, CCA main component of copper and arsenic, ACQ main component of ammonia-soluble alkylamine copper. Antiseptic wood according to the use of conditions to determine the dose of imitation agent, specifically to see the recent release of the national standard "anti-corrosion timber." There is no preservative preservative wood -------- carbonized wood. Carbonized wood is the effective nutrition of wood charcoal, by cutting off the survival of the nutritional chain to achieve the purpose of corrosion. Is a real green building materials, environmentally friendly building materials, US shell decoration to provide. Project preservative wood charcoal The process is to press the pressed wood into the wood by about 200 degrees high temperature treatment Treatment agent CCA or ACQ ---- Processing cycle 4 to 6 hours 32 to 48 hours Environmental protection is better Better dimensional stability, better than teak Moisture expansion is better, better than teak Anti-pest control is good, quite use grade 2/3 Anti-cracking performance Easy to crack outdoors is almost no cracking Good strength fell about 10-20% Use restrictions Restricted use of places where contact with humans and animals is not recommended for use in the carrier Color yellowish green according to the handling conditions, golden brown In the interior decoration, it is recommended to use carbonized wood.

- Q: Antiseptic wood brush a few anti-corrosion paint

- Surface protection paint or oil-based paint after brushing (only once) in order to achieve the best results, within 48 hours to avoid moving or moving heavy objects, so as not to damage the preservative wood surface has formed a protective film.

- Q: A piece of wood in some places where the implementation of green material? Is the wood eh, sandpaper sanding useful?

- Green that is mainly anti-corrosion agent color, you can polish after brushing woody wood. So that the color difference of the wood can be made smaller.

- Q: Fine decoration, design instructions and specifications are required ceiling wood materials and keel and so on to do anti-corrosion requirements. Will the wood keel anti-corrosion how to deal with the fire, the order is how? What is the better craft now? (Say brush paint asphalt, there are soaked anti-corrosion fire retardant coating (anti-corrosion fire together bubble), there are said wood preservative) Light steel keel anti-corrosion how to deal with fire? Finally, the wood keel moth treatment with anti-corrosion fire is the order of how? Please decorate up to help! Greatful!

- Wood keel direct brush fire retardant paint, light steel keel does not do any treatment, outdoor and humid place with tung oil soaked anti-corrosion.

Send your message to us

Anticorrosive Best Quality Deep Carbonized Birch Wood

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1x20' FCL m.t.

- Supply Capability:

- 1500 CBM m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords