Anti-Slip Tape with PVC Popular Design Hot Sales BOPP Packaging Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Anti-slip Tape with PVC Popular Design Hot Sales

1. Structure of Anti-slip Tape Description

base glue: ready-to-use waterproof strong viscose

base paper: white/leather silicone paper

middle layer: PET, PP, PVC and aluminum, etc.

surface: choice anti-slip sand, rubber anti-slip fiber, sand-free special anti-slip material;

2. Main Features of Anti-slip Tape

Resistance to cold, heat

- High Temperature stability

Excellent in adhesion

High mechanical strength

Good impact resistance

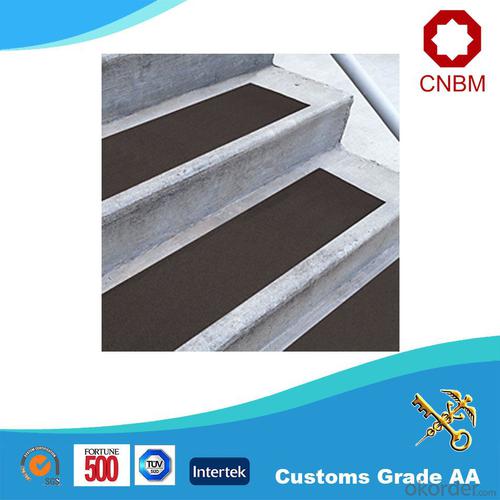

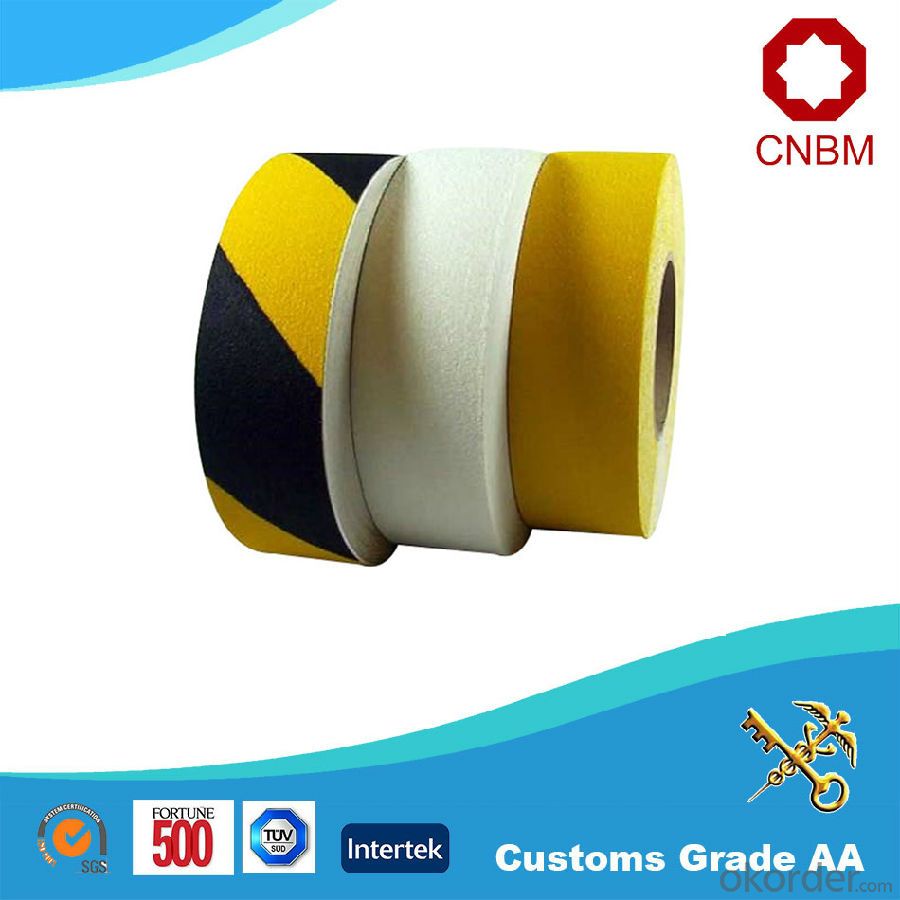

3. Anti-slip Tape Images

4. Anti-slip Tape Description

Item No. | Carrier | Thickness (c) | Anti-skid sand | Surface granularity |

CN-1101 | PVC film | 10 | black corundum | 60 items |

CN-1102 | PVC film | 8 | black corundum | 90 items |

CN-1105 | PVC film | 9 | black corundum | 110 items |

CN-1106 | PVC film | 10 | black corundum | 120 items |

CN-1107 | PVC film | 25 | black corundum | 40 items |

CN-1108 | PET film | 5 | silicon carbide | 40 items |

5. FAQ

Q1. Why choose us?

20 Years Experience USD1.6 billion yearly sales

World Top 500 Enterprise

OEM service, supported by strong R&D team

A short lead time

Quality guarantee with third party certification

One-step service: transportation, capital etc.

Q2. What can we do for you?

Professional consultation on your local market

Custom-made advices for your need

Free samples of Anti-slip tape

Your inquiry will be replied within 12 hours.

Well-trained & experienced sales representative are ready to answer you.

Satisfactory sales service

Q3. Delivery time

7-25 days after receiving the deposit.

- Q: Can packaging tape be used for sealing glass bottles?

- Yes, packaging tape can be used for sealing glass bottles. However, it is important to note that it may not provide the same level of security and protection as specialized bottle sealing methods such as corking or using bottle caps. Packaging tape may not be as effective in preventing leakage or maintaining the freshness of the contents.

- Q: Can packaging tape be used for sealing perishable food items?

- No, packaging tape should not be used for sealing perishable food items. Packaging tape is typically made of materials like polypropylene or PVC, which are not food-safe and can potentially contaminate the food. Moreover, packaging tape is not designed to provide an airtight seal, which is crucial for preserving the freshness and preventing spoilage of perishable food items. It is recommended to use appropriate food-safe sealing methods such as ziplock bags, airtight containers, or food-grade cling wrap to ensure the safety and quality of perishable food items.

- Q: Can packaging tape be used for sealing PVC pipes?

- No, packaging tape should not be used for sealing PVC pipes. PVC pipes require a specific type of sealant that is designed to bond with the PVC material and create a watertight seal. Packaging tape is not designed for this purpose and may not provide a secure and durable seal. It is recommended to use PVC pipe sealant or plumber's tape specifically designed for sealing PVC pipes to ensure a proper and long-lasting seal.

- Q: Can packaging tape be used for sealing arts and crafts materials?

- Yes, packaging tape can be used for sealing arts and crafts materials. It provides a strong and secure bond, making it suitable for various types of materials such as paper, cardboard, and plastic. However, it is important to consider the aesthetics and longevity of the tape, as there may be more specialized options available for specific art and craft projects.

- Q: Can packaging tape be used for sealing packages with electronics or electrical components?

- Yes, packaging tape can be used for sealing packages with electronics or electrical components. However, it is important to note that not all packaging tapes are suitable for this purpose. When selecting a packaging tape for sealing packages with electronics or electrical components, it is recommended to choose an anti-static or ESD (electrostatic discharge) safe tape. These tapes are specifically designed to prevent static electricity from damaging sensitive electronic components during shipping or handling. Using regular packaging tape without anti-static properties may pose a risk of static discharge that could potentially damage the electronics or affect their performance. Therefore, it is crucial to consider the specific requirements of the electronics or electrical components being packaged and select an appropriate tape to ensure their protection.

- Q: Does packaging tape come in different widths for different applications?

- Packaging tape indeed comes in a variety of widths to suit different purposes. You can find packaging tape in a range of widths, starting from as little as 0.75 inches and going up to 3 inches or even wider. The width you choose depends on the specific task at hand and the size of the package you are sealing. When dealing with lighter packages or sealing small boxes or envelopes, it is common to opt for narrower widths. Conversely, wider tape is frequently used when dealing with heavy-duty or larger boxes that require added strength and security. With the availability of different widths, users can easily select the most suitable tape size based on their unique packaging requirements.

- Q: Is packaging tape resistant to chemicals or solvents?

- Yes, packaging tape is generally resistant to chemicals or solvents. Most packaging tapes are made from materials such as polypropylene or polyvinyl chloride (PVC) which have good chemical resistance properties. These materials are designed to withstand exposure to a wide range of chemicals and solvents commonly encountered in industrial or commercial environments. However, it is important to note that the specific resistance of packaging tape can vary depending on the brand, type, and quality of the tape. Therefore, it is always recommended to check the product specifications or consult the manufacturer for detailed information on the chemical resistance of a specific tape.

- Q: Is packaging tape safe for use on painted surfaces or walls?

- Packaging tape is generally safe for use on painted surfaces or walls. However, it is important to exercise caution and follow proper techniques to minimize any potential damage. When applying packaging tape on painted surfaces or walls, it is recommended to test a small, inconspicuous area first to ensure that the tape does not peel off or damage the paint. Additionally, it is advisable to remove the tape gently and slowly to avoid any paint peeling or residue left behind. If the paint is delicate or the tape has been left on for an extended period, there is a possibility that the tape may cause some minor damage, such as slight paint discoloration or removal. Therefore, it is always a good idea to handle packaging tape with care and take necessary precautions to protect the painted surfaces or walls.

- Q: What's the tape for sealing tape?

- The base material of the sealing adhesive tape is BOPP film.BOPP is a very important flexible packaging material, and has been widely used. BOPP film is colorless, odorless, tasteless, non-toxic, and has high tensile strength, impact strength, rigidity, toughness and good transparency. It is a high quality substrate for making transparent sealing tape. BOPP film has low surface energy, and it needs corona treatment before gluing or printing. However, the BOPP film has good printing adaptability after corona treatment. It can be printed by printing and has a beautiful appearance, so it is often used as the surface material of composite films. BOPP film is also inadequate, such as easy accumulation of static electricity, no heat sealing and so on. In the high-speed production line, BOPP film is easy to generate static electricity. Electrostatic eliminator is necessary. In order to obtain the BOPP heat seal film, can be on the surface of BOPP film after corona treatment coating heat sealing resin glue, such as PVDC, EVA latex latex, can also be coated with solvent glue, coating or extrusion method can be applied to the production of extruded composite heat sealing film BOPP. The film is widely used in bread, clothing, footwear and other packaging, and cigarettes, books cover packaging. The tear strength of BOPP film increases after stretching, but the secondary tearing strength is very low. Therefore, no cut can be left at the ends of the BOPP film, otherwise the BOPP film is easy to tear when printed and compounded. BOPP coated self-adhesive, we can produce our commonly used sealing tape, tape sealing tape, is a larger amount of BOPP market.

- Q: Can packaging tape be used for sealing electrical or wiring components?

- No, packaging tape should not be used for sealing electrical or wiring components. Packaging tape is not designed to provide insulation or protection against electrical currents. It lacks the necessary properties to ensure the safety and reliability of electrical connections. It is important to use appropriate electrical tape or other specialized materials that are specifically designed for sealing and insulating electrical components.

Send your message to us

Anti-Slip Tape with PVC Popular Design Hot Sales BOPP Packaging Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords