Stickermule Eco-Friendly Anti-Slip Tape for Pet Carriers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Anti-slip Tape with PET Carrier Environmentally Friendly

1. Structure of Anti-slip Tape Description

base paper: white/leather silicone paper

base glue: ready-to-use waterproof strong viscose

surface: choice anti-slip sand, rubber anti-slip fiber, sand-free special anti-slip material;

middle layer: PET, PP, PVC and aluminum, etc.

2. Main Features of Anti-slip Tape

Excellent in adhesion

Resistance to cold, heat

High Temperature stability

Provide Pattern

High mechanical strength

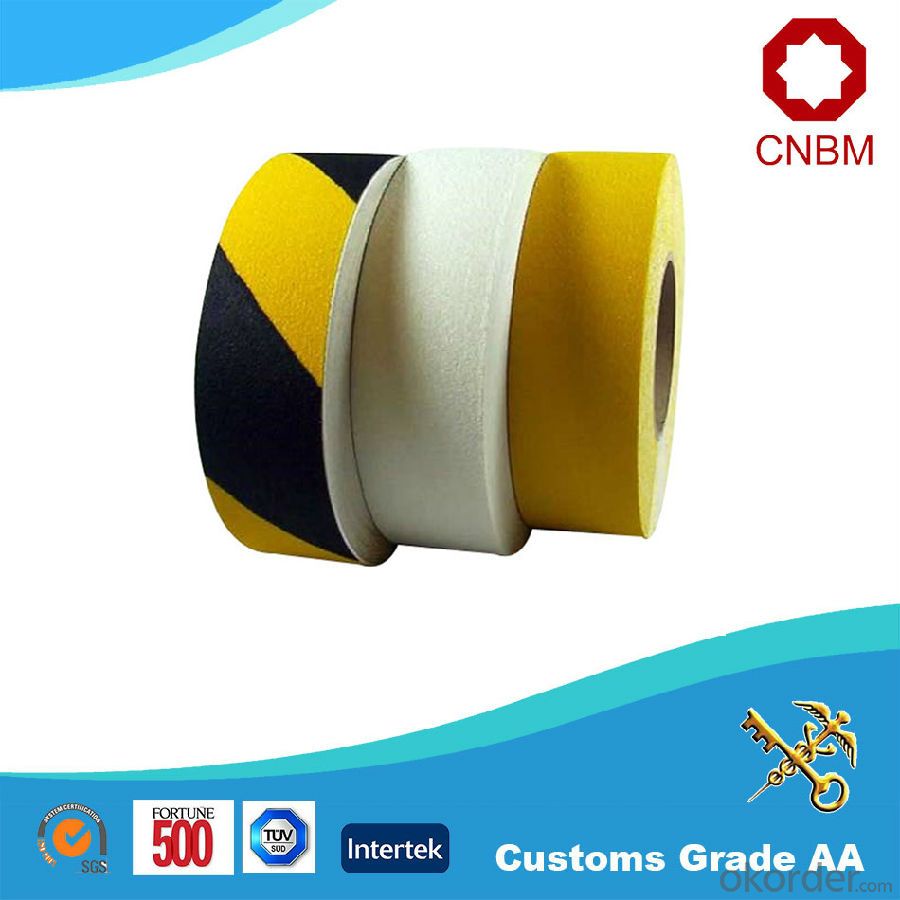

3. Anti-slip Tape Images

4. Anti-slip Tape Description

Item No. | Carrier | Thickness (c) | Anti-skid sand | Surface granularity |

CN-1107 | PVC film | 10 | black corundum | 120 items |

CN-1108 | PET film | 5 | silicon carbide | 40 items |

CN-1109 | PET film | 5 | white corundum | 60 items |

CN-1111 | PET film | 5 | silicon carbide | 100 items |

CN-1113 | PP film | 5.4 | white corundum | 60 items |

CN-1114 | PP film | 5.4 | white corundum | 80 items |

CN-1116 | PP film | 5.4 | white corundum | 120 items |

5. FAQ

Q1. What can we do for you?

24 hours service for you

Professional consultation on your local market

Custom-made advices for your need

Your inquiry will be replied within 12 hours.

Satisfactory sales service

Q2.What are the colors of Anti-slip Tape?

black, gray, red, orange, blue, between yellow and black, red and white, transparent, white, reflective, night light-emitting, etc. printing a variety of beautiful picture and patterns according with customer requirements

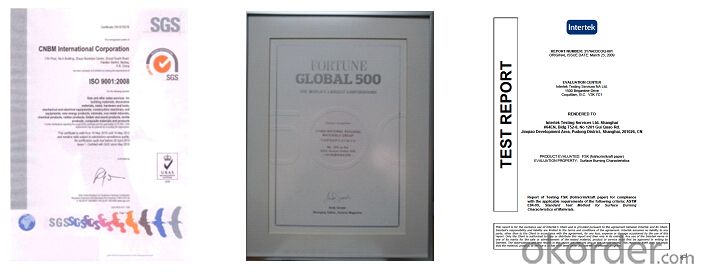

Q3. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Can packaging tape be used for sealing arts and crafts materials?

- Yes, packaging tape can be used for sealing arts and crafts materials. It provides a strong and secure bond, making it suitable for various types of materials such as paper, cardboard, and plastic. However, it is important to consider the aesthetics and longevity of the tape, as there may be more specialized options available for specific art and craft projects.

- Q: Can packaging tape be used for sealing furniture or home goods?

- Yes, packaging tape can be used for sealing furniture or home goods. It provides a strong adhesive bond and helps secure the packaging, protecting the items during transportation or storage.

- Q: Does packaging tape come in different allergen-free options?

- Yes, packaging tape does come in different allergen-free options. Many manufacturers offer packaging tape that is specifically designed to be hypoallergenic and free from common allergens such as latex, gluten, and other potential irritants. These allergen-free options are particularly beneficial for individuals with sensitive skin or allergies. It is always recommended to carefully read the product labels or descriptions to ensure that the packaging tape meets your specific allergen-free requirements.

- Q: Can packaging tape be used for sealing paper bags?

- Indeed, paper bags can be securely sealed with packaging tape. Possessing robust adhesive properties, packaging tape effectively adheres to diverse surfaces, including paper. When appropriately applied, it furnishes a dependable and safeguarding seal for paper bags, effectively shielding their contents from spillage or external influences. To optimize adhesion, it is crucial to ascertain that the surface of the paper bag is both clean and dry prior to tape application.

- Q: How do I prevent packaging tape from yellowing over time?

- To prevent packaging tape from yellowing over time, it is essential to store it in a cool, dry, and dark place. Exposure to sunlight and humidity can accelerate the yellowing process. Additionally, using high-quality packaging tape made from materials resistant to discoloration can help maintain its original appearance for a longer period.

- Q: Is packaging tape safe for use on leather or fabric items?

- Packaging tape is generally not recommended for use on leather or fabric items. While it may provide a temporary solution for holding things together, it is not designed to be used on delicate materials like leather or fabric. Packaging tape is typically made of a strong adhesive that can leave residue or even damage the surface of these items. Additionally, the tape's adhesive may not be strong enough to securely hold the materials together, resulting in the tape peeling off easily and potentially causing damage to the item. It is best to use specific types of tape that are specifically designed for use on leather or fabric, such as double-sided fabric tape or leather repair tape, which provide a safer and more effective solution for repairing or securing these materials.

- Q: What are the alternatives to packaging tape?

- There are several alternatives to packaging tape that can be used for securing packages or boxes. Some of the popular alternatives include: 1. Duct Tape: Duct tape is a strong adhesive tape that can be used as an alternative to packaging tape. It is known for its durability and ability to stick to various surfaces. 2. Masking Tape: Masking tape is a type of adhesive tape that is less sticky compared to packaging tape. It is commonly used in painting or crafting projects, but can also be used to secure packages. 3. String or Twine: String or twine can be used to secure packages by wrapping it around the box and tying it securely. This method is often used for packages that do not require strong adhesion. 4. Packaging Straps: Packaging straps are commonly made of plastic or polyester and can be used to secure packages by strapping them tightly around the box. They provide a strong and secure alternative to packaging tape. 5. Adhesive Glue: Adhesive glue can be used as an alternative to packaging tape, particularly for small packages or envelopes. It is essential to choose a glue that is strong enough to securely seal the package. 6. Paper or Kraft Tape: Paper or kraft tape is a water-activated tape that is commonly used for sealing packages. It requires wetting the tape to activate the adhesive, providing a strong and secure seal. 7. Zip Ties: Zip ties are plastic ties that can be used to secure packages by fastening them tightly around the box. They are commonly used for securing large or heavy packages. When considering alternatives to packaging tape, it is important to assess the specific needs of the package, such as its size, weight, and handling requirements, to determine the most suitable option.

- Q: Can packaging tape be used for sealing wooden furniture?

- Indeed, wooden furniture can indeed be sealed with packaging tape. Although it may not be the most traditional or visually appealing choice, packaging tape can effectively close off any gaps or cracks in the furniture, thus preventing the infiltration of dust, moisture, or insects. It should be noted, however, that packaging tape is not a permanent solution, as it may not offer the same level of durability or stability as sealing methods explicitly crafted for wooden furniture, such as wood glue or epoxy. Consequently, it is advisable to employ packaging tape as a temporary remedy until a more suitable sealing technique can be implemented.

- Q: Can packaging tape be used for sealing packages with perishable items?

- Packaging tape is not ideal for sealing packages with perishable items. While it may provide a temporary seal, it is not designed to withstand the unique challenges that come with packaging perishable goods. Perishable items, such as food or flowers, require specialized packaging materials that can provide insulation, maintain temperature control, and prevent moisture or air leakage. These materials are designed specifically to protect perishable items during transportation and storage. Therefore, it is recommended to use appropriate packaging materials like insulated bags, coolers, or specialized packaging solutions when sealing packages containing perishable items to ensure their freshness and quality.

- Q: How does packaging tape perform in high-pressure conditions?

- Packaging tape is designed to perform well in high-pressure conditions. It is typically made from strong and durable materials such as polypropylene or polyester, which can withstand pressure, tension, and stress. These tapes have excellent adhesive properties that enable them to bond securely with various surfaces, even under high pressure. Additionally, packaging tapes are often equipped with features like reinforced fibers or water-activated adhesives, which further enhance their performance in demanding conditions. Overall, packaging tape is reliable and effective for sealing and securing packages, even in high-pressure environments.

Send your message to us

Stickermule Eco-Friendly Anti-Slip Tape for Pet Carriers

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 3000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords