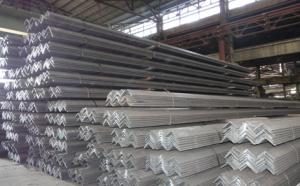

Angle

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specifications of Angle Steel

1. Invoicing on theoretical weight or actual weight as customer request

2. Length: 6m, 9m, 12m as following table

3. Sizes

Sizes: 25mm-250mm | ||

a*t | ||

25*2.5-4.0 | 70*6.0-9.0 | 130*9.0-15 |

30*2.5-6.6 | 75*6.0-9.0 | 140*10-14 |

36*3.0-5.0 | 80*5.0-10 | 150*10-20 |

38*2.3-6.0 | 90*7.0-10 | 160*10-16 |

40*3.0-5.0 | 100*6.0-12 | 175*12-15 |

45*4.0-6.0 | 110*8.0-10 | 180*12-18 |

50*4.0-6.0 | 120*6.0-15 | 200*14-25 |

60*4.0-8.0 | 125*8.0-14 | 250*25 |

5. Payment terms:

1).100% irrevocable L/C at sight.

2).30% T/T prepaid and the balance against the copy of B/L.

3).30% T/T prepaid and the balance against L/C

6.Material details:

Alloy No | Grade | Element (%) | | ||||

C | Mn | S | P | Si | | ||

| | |||||||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | | ||||

Thickness (mm) | | ||||||

≤16 | >16--40 | >40--60 | >60--100 | | |||

≥ | | ||||||

|

|

|

|

|

| | |

Q235 | B | 235 | 225 | 215 | 205 | | |

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | | |||

Thickness (mm) | | ||||||

| ≤16 | >16--40 | >40--60 | >60--100 | | ||

≥ | | ||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications of Angle Steel

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Angle Steel

1. Packing: it is nude packed in bundles by steel wire rod

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

Production flow of Angle Steel

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: How are steel wire rods used in the manufacturing of mesh screens for filtration and separation?

- Steel wire rods are used in the manufacturing of mesh screens for filtration and separation by being woven together to form a strong and durable mesh structure. These rods provide the necessary strength and rigidity to support the mesh and ensure it can withstand the pressure and demands of the filtration and separation processes.

- Q: What are the main challenges in manufacturing steel wire rod?

- Some of the main challenges in manufacturing steel wire rod include ensuring consistent quality and strength, maintaining a high level of productivity, managing energy consumption and environmental impact, and addressing safety concerns in the production process. Additionally, market fluctuations and competition pose challenges in terms of pricing and meeting customer demands.

- Q: How is steel wire rod used in the manufacturing of wire mesh filters?

- Steel wire rod is used in the manufacturing of wire mesh filters as it provides the raw material for creating the wire mesh. The wire rod is typically drawn and processed to form thin, high-quality wires which are then woven or welded together to create the mesh structure of the filter. The steel wire rod's strength, durability, and flexibility make it ideal for producing wire mesh filters that can effectively trap and filter particles while maintaining structural integrity.

- Q: What are the common joining methods for steel wire rod?

- The common joining methods for steel wire rod include welding, crimping, and mechanical fastening methods such as bolts and nuts.

- Q: How is steel wire rod used in the manufacturing of wire meshes?

- Steel wire rod is used in the manufacturing of wire meshes as the primary raw material. The wire rod is drawn, stretched, and twisted to form the wires that are then woven or welded together to create the desired mesh pattern. The steel wire rod provides strength, durability, and flexibility to the wire mesh, making it suitable for various applications such as fencing, construction, filtration, and reinforcement.

- Q: How are steel wire rods used in the manufacturing of piano strings?

- Steel wire rods are used in the manufacturing of piano strings as they provide the necessary strength and flexibility required for producing high-quality and durable strings.

- Q: How is steel wire rod cut to desired lengths?

- Wire drawing is a common method used to cut steel wire rod into desired lengths. By pulling the steel rod through a series of dies, its diameter gradually decreases. This not only shapes the wire to the desired size but also enhances its strength and flexibility. The wire drawing process can be carried out either manually or with automated machinery, depending on the production scale. Once the wire reaches the desired diameter, it can be cut into specific lengths using various cutting techniques, such as shearing or sawing. These cutting methods can be performed manually or with specialized cutting equipment. In conclusion, the process of cutting steel wire rod to desired lengths involves shaping the wire through wire drawing and then using appropriate cutting methods for precision.

- Q: What are the growth drivers for the steel wire rod industry?

- There are several growth drivers for the steel wire rod industry. One of the main drivers is the increasing demand for steel wire rods in construction and infrastructure projects worldwide. The expanding urbanization and industrialization in emerging economies are driving the need for steel wire rods in various applications such as reinforcing concrete structures and manufacturing wire products. Another growth driver is the growing automotive industry, which utilizes steel wire rods extensively in the production of automobile components and parts. As the demand for automobiles continues to rise, so does the demand for steel wire rods. Furthermore, the growth of the energy sector, particularly in renewable energy sources such as wind and solar power, is also driving the demand for steel wire rods. These rods are used in the construction of wind turbines, solar panels, and transmission lines, among other applications. Lastly, the increasing focus on sustainability and eco-friendly practices is leading to the adoption of steel wire rods as a substitute for other materials like plastic in various industries. This shift towards environmentally friendly solutions is expected to further drive the growth of the steel wire rod industry.

- Q: What is the hardness range of steel wire rod?

- The hardness range of steel wire rod typically varies between 350 to 550 on the Brinell hardness scale.

- Q: What are the different types of steel wire rod coatings used for corrosion resistance?

- There are several different types of steel wire rod coatings that are commonly used for corrosion resistance. These coatings can provide a protective barrier that helps prevent the steel wire rod from being exposed to moisture and chemicals, which can cause corrosion. Some of the most common coatings include: 1. Zinc Coating: This is one of the most widely used coatings for steel wire rod. Zinc coating, also known as galvanization, involves applying a layer of zinc to the surface of the wire rod. The zinc acts as a sacrificial anode, meaning that it corrodes before the steel wire rod does, thereby protecting it from corrosion. 2. Epoxy Coating: Epoxy coatings are often used for steel wire rod that will be exposed to harsh environments or chemicals. These coatings provide excellent corrosion resistance and can withstand high temperatures. Epoxy coatings are typically applied through a process called electrostatic spray deposition. 3. Polymer Coating: Polymer coatings are another popular choice for corrosion resistance. These coatings are typically made from thermoplastic or thermosetting materials and can be applied by dipping, spraying, or extrusion. Polymer coatings provide a durable and flexible barrier against moisture and chemicals. 4. Ceramic Coating: Ceramic coatings are often used for steel wire rod that will be exposed to extreme temperatures or abrasive environments. These coatings provide excellent corrosion resistance, as well as high thermal and chemical stability. Ceramic coatings are typically applied through a process called thermal spraying. 5. Phosphate Coating: Phosphate coatings are commonly used as a pre-treatment for steel wire rod before applying other protective coatings. These coatings provide a thin layer of phosphate on the surface of the wire rod, which improves adhesion and corrosion resistance of subsequent coatings. Overall, the choice of steel wire rod coating depends on the specific application and the level of corrosion resistance required. Each type of coating offers unique benefits and can be tailored to meet the specific needs of the wire rod.

Send your message to us

Angle

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords