Aluminum Pipes for Subway Aluminum Profile

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

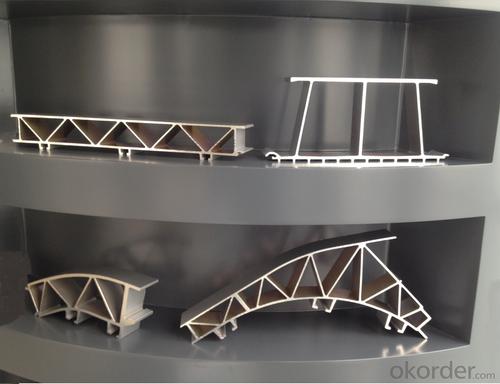

We are the largest aluminum profilemanufacture in

Material | Alloy Aluminum 6063,6061,6005,6082 or customer nominated |

Temper | T3, T4, T5, T6 and other |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Not more than 16 meters |

Good Package | Inner plastic film /outside carton/wooden pallets |

Payment Method | T/T, L/C, etc |

Delivery Time | Normally 2-4 weeks, Delivery time can be consulted. |

Press Machine | 500-12500 tons all together 93 press lines. |

Fabrication | 1. Subway; 2. Drilling; 3. Welding; 4. Cutting; 5. etc. |

Certificate | ISO/TS 16949,DNV,IRIS,CCS,AFA,etc. |

Dies | 1. Using our dies, no fee; |

2. Using customer drawing, opening dies, usually about 5~50 tons then the dies cost can be refunded. | |

3. Die cost is negotiable base on the order quantity | |

Capability | Annual output 800,000 tons |

- Q: Are aluminum pipes easy to install?

- Yes, aluminum pipes are generally easy to install. They are lightweight, which makes handling and maneuvering them much easier compared to other materials. Aluminum pipes also have a smooth surface, which allows for easy insertion and connection. Additionally, aluminum pipes can be easily cut and shaped to fit specific requirements, making the installation process more flexible. However, it is important to note that proper tools and techniques should be used to ensure a secure and leak-free installation.

- Q: What are the different pressure testing standards for aluminum pipes?

- Aluminum pipes commonly undergo pressure testing according to various standards. Some widely recognized standards include the following: 1. ASTM B-241: This standard specifically applies to seamless aluminum-alloy pipes. Its purpose is to assess the pipes' pressure capabilities under different conditions. It outlines guidelines for evaluating the pipes' strength, thickness, and ability to withstand internal and external pressures. 2. ASME B31.3: This standard forms part of the American Society of Mechanical Engineers (ASME) code for process piping. It establishes requirements and guidelines for the design, fabrication, inspection, and testing of aluminum pipes in various industries. It includes specific procedures for pressure testing and criteria for accepting aluminum pipes. 3. ISO 6892: This international standard sets out testing methods for metallic materials, including aluminum. It incorporates procedures for determining the mechanical properties of aluminum pipes, such as tensile strength, yield strength, and elongation. Although not primarily focused on pressure testing, it provides valuable information about the overall strength and performance of aluminum pipes. 4. MIL-PRF-6855: This military standard specifies the requirements for rubber and polyurethane hoses used in aircraft fuel systems. While not exclusively for aluminum pipes, it contains pressure testing standards and criteria that apply to aluminum pipes in aviation applications. It is important to note that these are merely a few of the commonly used pressure testing standards for aluminum pipes. Depending on the specific application and industry, additional standards or guidelines may be necessary to follow. It is always advisable to consult the relevant industry standards and codes to ensure compliance with specific pressure testing requirements.

- Q: What are the common insulation materials used for aluminum pipes?

- Aluminum pipes can be insulated using various materials including fiberglass, foam rubber, polyethylene, and elastomeric foam. Among these, fiberglass insulation is widely preferred due to its exceptional thermal performance and fire resistance. Moreover, it is resistant to moisture, mold, and corrosion, making it suitable for both indoor and outdoor applications. On the other hand, foam rubber insulation offers good thermal insulation and is easy to install, making it commonly used for smaller diameter pipes. Polyethylene insulation is renowned for its low thermal conductivity and moisture resistance, making it suitable for both hot and cold water pipes. Lastly, elastomeric foam insulation is a flexible and lightweight material that provides excellent thermal and acoustic insulation. It is typically used for HVAC systems and refrigeration pipes. In summary, these insulation materials effectively protect aluminum pipes from heat loss or gain, thereby enhancing overall energy efficiency.

- Q: How do aluminum pipes perform in extreme temperatures?

- Aluminum pipes exhibit exceptional performance under extreme temperatures, renowned for their excellent capabilities. They possess a remarkable melting point of approximately 660 degrees Celsius, rendering them highly resistant to heat. This quality endows them with the ability to endure elevated temperatures without experiencing deformation or structural impairment. Furthermore, aluminum boasts a low coefficient of thermal expansion, ensuring minimal expansion or contraction when subjected to drastic temperature fluctuations. This characteristic enables the aluminum pipes to maintain their original shape and structural integrity, regardless of hot or cold conditions. Additionally, due to its proficient heat conductivity, aluminum proficiently dissipates and transfers heat, effectively averting pipe overheating. Consequently, aluminum pipes are exceedingly dependable and exhibit exceptional performance in environments characterized by extreme temperatures.

- Q: Can aluminum pipes be used for underground electrical conduits?

- Underground electrical conduits can indeed utilize aluminum pipes. Aluminum, a lightweight and resilient material, finds extensive use in various applications, including electrical conduits. However, several factors warrant attention when employing aluminum pipes for underground electrical conduits. Primarily, safeguarding aluminum pipes against corrosion is crucial. Aluminum is prone to corrosion, particularly on contact with certain soils or moisture. To counter this, it is essential to employ corrosion-resistant coatings or adopt protective measures, such as enveloping the pipes with suitable materials. Secondly, ensuring proper grounding is imperative for aluminum pipes. Unlike copper, which is commonly used for electrical wiring due to its high conductivity, aluminum possesses comparatively lower conductivity. Therefore, it becomes vital to establish adequate grounding to sustain electrical conductivity and ensure safety. Thirdly, compliance with local electrical codes and regulations is paramount when utilizing aluminum pipes for underground electrical conduits. Distinct regions may enforce specific requirements and standards for underground electrical installations. Accordingly, adhering to these guidelines becomes indispensable for guaranteeing the electrical system's efficiency and safety. In conclusion, aluminum pipes can be employed for underground electrical conduits, but taking appropriate precautions to combat corrosion, ensuring proper grounding, and observing local codes and regulations is essential.

- Q: Please help to analyze the cause of the formation Fifty1070 aluminum rods are made of aluminum tubes from extrusion units. The process is: extrusion, melting - the mold passes through (the formation of aluminum tubes) - tap water cooling - closing - nitrogen charging and pressure maintaining. Therefore, the internal pipeline is nitrogen protection, and after a period of time, the pipeline will appear white powder, affecting resistance welding, welding is not firm, easy to fall off and leak.

- Landlord, that is the aluminum oxide (*^__^*) hee hee oh......

- Q: Are aluminum pipes resistant to saltwater corrosion?

- Yes, aluminum pipes are generally resistant to saltwater corrosion. Aluminum is known for its excellent corrosion resistance, including resistance to saltwater. It forms a thin, transparent oxide layer on its surface when exposed to oxygen, which acts as a protective barrier against corrosion. This oxide layer helps to prevent the metal from reacting with saltwater, thus making aluminum pipes highly resistant to saltwater corrosion. However, it is important to note that prolonged exposure to saltwater can still lead to some degree of corrosion over time, but compared to other metals, aluminum is considered to be one of the most corrosion-resistant materials for saltwater applications.

- Q: Can aluminum pipes be used for geothermal heating systems?

- Indeed, geothermal heating systems can make use of aluminum pipes. The popularity of aluminum in the construction of geothermal heat exchangers is due to its remarkable heat transfer capabilities. With its high thermal conductivity, aluminum effectively transfers heat from the earth to the fluid flowing within the pipes. Moreover, aluminum is renowned for being lightweight, resistant to corrosion, and possessing a long lifespan, rendering it a durable and economical choice for geothermal heating systems. Nevertheless, it is crucial to insulate the aluminum pipes appropriately to minimize heat loss and optimize the system's efficiency.

- Q: What are the advantages of using aluminum pipes?

- There are several advantages of using aluminum pipes. Firstly, aluminum pipes are lightweight, making them easier to handle and transport compared to other metals such as steel. Secondly, aluminum is corrosion-resistant, ensuring that the pipes have a longer lifespan and require less maintenance. Additionally, aluminum pipes have excellent heat conductivity, making them suitable for applications that involve heat transfer. Lastly, aluminum is a highly recyclable material, making it an environmentally friendly choice.

- Q: Are aluminum pipes suitable for chemical storage facilities?

- Due to their potential reactivity with certain chemicals, aluminum pipes might not be the optimal choice for chemical storage facilities. Although aluminum is typically resistant to corrosion, it can still undergo reactions with certain acids and alkaline substances, resulting in damage and potentially jeopardizing the pipes' integrity. Moreover, aluminum pipes may lack the essential strength and durability necessary for the safe handling and storage of chemicals. To identify the most suitable pipes for specific chemical storage requirements, it is recommended to seek advice from a chemical engineer or a material compatibility expert.

Send your message to us

Aluminum Pipes for Subway Aluminum Profile

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords