Aluminum Pig/Ingot Popular Sold 2015 With Best Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Pure Aluminum Pig/Ingot Used for Industry

1.Structure of Aluminum Pig/Ingot

A material that has been cast into a shape in order to be transported and processed easier than in an unprocessed form. An ingot is typically rectangular in shape, which allows it to be stacked. Ingots are most commonly associated with metals, with ingots of gold held in the vaults of banks and brokerages being popular images.

Aluminum Ingot is with the AL as the main chemical composition.Aluminum Ingot is used for industry,such as automobile,pinning and weaving,electron broadly and so on. Aluminum Ingot has the following advantages: easy control and operation, fast melting.

2.Main Features of the Aluminum Pig/Ingot

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

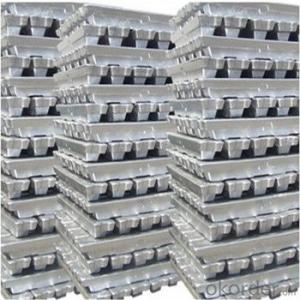

3.Aluminum Pig/Ingot Images

4.Aluminum Pig/Ingot Specification

Grade | Chemical Composition % | |||||||||

Al≥ | impurities ≤ | |||||||||

Si | Fe | Cu | Ga | Mg | Zn | Mn | others | Sum | ||

Al99.9 | 99.90 | 0.50 | 0.07 | 0.005 | 0.02 | 0.01 | 0.025 | - | 0.010 | 0.10 |

Al99.85 | 99.85 | 0.80 | 0.12 | 0.005 | 0.03 | 0.02 | 0.030 | - | 0.015 | 0.15 |

Al99.7 | 99.70 | 0.10 | 0.20 | 0.010 | 0.03 | 0.02 | 0.030 | - | 0.030 | 0.30 |

Al99.6 | 99.60 | 0.16 | 0.25 | 0.010 | 0.03 | 0.03 | 0.030 | - | 0.030 | 0.40 |

Al99.5 | 99.50 | 0.22 | 0.30 | 0.020 | 0.03 | 0.05 | 0.050 | - | 0.030 | 0.50 |

Al99.00 | 99.00 | 0.42 | 0.50 | 0.020 | 0.03 | 0.05 | 0.050 | - | 0.050 | 1.00 |

5.FAQ of Aluminum Pig/Ingot

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A professional factory which foucs on producing the aluminum pig,can meet customers' requiement to the quality and grade.The quality also have been accepted by customer.Already got the good reputation among the customers.It have gotten lot of much experience.The facrtory has the professional Technical Worker and the advanced equipments for production.Beside,it has the profesional teams to operate the whole proess for exporting.OEM service is availble and welcome.The items have beedn exported around the world,and have been acceptable among the customers,and have gotten the good reputation already.No matter from the quality,price and service,can be guaranteed for the cusgtomers.High purity and diffent grade are available.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the prod rking days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: How are aluminum ingots used in the production of electronic devices?

- Aluminum ingots are primarily used in the production of electronic devices as a material for creating casings and housings. The ingots are melted and shaped into desired forms, providing a lightweight yet durable structure for electronic devices such as smartphones, laptops, and tablets. Aluminum's excellent thermal conductivity also helps in dissipating heat generated by electronic components, ensuring optimal performance and preventing overheating issues. Additionally, the corrosion-resistant properties of aluminum make it a popular choice for protecting electronic circuits from external elements.

- Q: What industries use aluminum ingots?

- Aluminum ingots are utilized by several industries due to their versatile properties and wide range of applications. Major industries heavily reliant on aluminum ingots include: 1. The automotive industry utilizes aluminum ingots to manufacture engine blocks, wheels, frames, and body panels. Aluminum's lightweight nature, corrosion resistance, and excellent thermal conductivity make it a preferred choice for improving fuel efficiency and reducing vehicle weight. 2. In the aerospace industry, aluminum ingots are extensively used to manufacture aircraft structures, wings, fuselage panels, and other components. Aluminum's high strength-to-weight ratio is ideal for building lightweight aircraft capable of withstanding the stresses of flight. 3. The construction industry relies on aluminum ingots for applications like windows, doors, roofing, and cladding systems. Aluminum's corrosion resistance, durability, and aesthetic appeal make it a popular choice for modern architectural designs. 4. The packaging industry extensively uses aluminum ingots to produce aluminum foils, cans, containers, and closures. Aluminum's excellent barrier properties, lightness, and recyclability make it a preferred material for preserving and protecting perishable items. 5. The electrical industry heavily depends on aluminum ingots to manufacture power transmission cables, electrical conductors, and wiring systems. Aluminum's high electrical conductivity, low weight, and cost-effectiveness make it a suitable alternative to copper in many electrical applications. 6. The marine industry employs aluminum ingots for fabricating boat hulls, masts, decks, and various components. Aluminum's corrosion resistance, lightness, and durability make it a preferred choice for constructing vessels that can withstand harsh marine environments. 7. The consumer goods industry utilizes aluminum ingots to manufacture cookware, furniture, appliances, and electronic devices. Aluminum's thermal conductivity, non-toxicity, and recyclability make it a popular material for consumer goods. These examples demonstrate the heavy reliance of various industries on aluminum ingots. Due to its advantageous properties, aluminum is widely used in machinery, transportation, energy, and even art and design sectors.

- Q: How much does it cost to process the aluminum ingots into T5-6063 models? Now, what about costing the aluminum ingot or the aluminum bar?

- T6 is artificially aged by solid solution heat treatmentIt is suitable for the products which are treated by solid solution heat treatment, no longer cold processing (can be straightened and leveling, but does not affect the mechanical performance limit)

- Q: What are the properties of aluminum ingots that make them suitable for construction?

- Aluminum ingots possess several properties that make them highly suitable for construction purposes. Firstly, aluminum is a lightweight material, weighing approximately one-third of the weight of steel. This characteristic makes it easier and more cost-effective to transport and handle during construction projects. Despite its lightweight nature, aluminum is also remarkably strong, offering a high strength-to-weight ratio. This property allows for the construction of sturdy and durable structures, capable of withstanding various loads and environmental conditions. Another significant property of aluminum ingots is their excellent corrosion resistance. Aluminum forms a natural oxide layer on its surface, which acts as a protective barrier against moisture, chemicals, and other corrosive elements. This resistance to corrosion ensures that aluminum structures remain intact and maintain their structural integrity over extended periods. Aluminum ingots are also known for their malleability and ductility. These properties make it easy to shape and mold the material into various forms and designs, enabling architects and engineers to create intricate and aesthetically pleasing structures. Additionally, aluminum can be easily fabricated, welded, and joined, allowing for flexibility in construction techniques and facilitating efficient installation processes. Furthermore, aluminum is a highly sustainable material. It is 100% recyclable without losing its inherent properties. This recyclability not only reduces the environmental impact of construction projects but also contributes to cost savings and resource conservation. Lastly, aluminum ingots have excellent thermal and electrical conductivity. This feature makes aluminum an ideal choice for construction projects that require efficient heat transfer, such as in heating, ventilation, and air conditioning systems, or electrical conductivity, as in wiring and electrical components. In conclusion, the properties of aluminum ingots, including their lightweight, strength, corrosion resistance, malleability, recyclability, and conductivity, make them highly suitable for construction. These properties contribute to the creation of durable, aesthetically pleasing, and environmentally friendly structures.

- Q: What are the main factors influencing the choice between aluminum ingots and aluminum slabs?

- The main factors influencing the choice between aluminum ingots and aluminum slabs include the specific application requirements, production processes, cost considerations, and transportation logistics.

- Q: How are impurities removed from aluminum ingots?

- Impurities are typically removed from aluminum ingots through a process called refining. This involves heating the ingots to a molten state and then introducing various fluxes or chemical agents that react with the impurities, causing them to separate and rise to the surface. The impurities are then skimmed off, leaving behind purified aluminum.

- Q: What are the different shapes and sizes of aluminum ingots?

- Aluminum ingots are available in a variety of shapes and sizes, depending on the specific needs of the industry they are utilized in. The rectangular shape is the most prevalent, with a length that can range from a few inches to several feet, and a width and height that adjust accordingly. These rectangular ingots are commonly employed in industries such as construction, automotive, and aerospace. In addition to rectangular ingots, cylindrical-shaped aluminum ingots are also present. These ingots possess a circular cross-section and can vary in terms of diameter and length. The uniform shape and ease of processing of cylindrical ingots make them a popular choice in the manufacturing of electrical components like wires and cables. Furthermore, aluminum ingots can also be found in less common shapes such as trapezoidal or triangular, which are often tailored to fulfill specific industrial requirements. These irregular-shaped ingots find their application in specialized areas where unique designs or specific mechanical properties are necessary. The sizes of aluminum ingots can vary significantly as well. Smaller ingots are usually employed for smaller-scale applications or for testing purposes, while larger ingots are used in heavy industries that demand large quantities of aluminum. Depending on their size and intended use, the weight of an aluminum ingot can range from a few pounds to several tons. In conclusion, the shapes and sizes of aluminum ingots are varied and can be customized to meet the specific demands of different industries and applications.

- Q: What are the advantages of using aluminum ingots in electrical applications?

- There are several advantages of using aluminum ingots in electrical applications. Firstly, aluminum is a lightweight metal, which makes it easier to handle and transport. Secondly, aluminum has excellent conductivity properties, allowing it to efficiently carry electrical current. Additionally, aluminum ingots are highly resistant to corrosion, making them durable and long-lasting in electrical applications. Lastly, aluminum is a cost-effective material compared to other metals, which makes it a more economical choice for electrical components.

- Q: How are aluminum ingots used in construction?

- Aluminum ingots are widely used in the construction industry for various applications due to their excellent properties and versatility. One common use of aluminum ingots in construction is for the manufacturing of structural components such as beams, columns, and trusses. The lightweight nature of aluminum makes it an ideal choice for these applications as it reduces the overall weight of the structure, leading to cost savings in transportation and installation. Additionally, aluminum ingots are used in the production of cladding systems, which are used to cover the exterior of buildings. These cladding systems provide aesthetic appeal, weather protection, and insulation to the structure. Aluminum's corrosion resistance and durability make it a preferred material for cladding, as it can withstand harsh weather conditions and maintain its appearance over an extended period. Moreover, aluminum ingots are employed in the fabrication of windows, doors, and curtain walls in construction projects. Aluminum frames offer strength and stability while providing a sleek and modern aesthetic. The material's corrosion resistance also ensures that these components remain durable and low-maintenance for a long time. Furthermore, aluminum ingots find applications in roofing systems. Aluminum roofs offer excellent resistance to corrosion, as well as being lightweight and durable. They are also highly reflective, which helps to reduce heat absorption and energy consumption, making them a sustainable choice for buildings. In conclusion, aluminum ingots play a crucial role in the construction industry. Their lightweight nature, corrosion resistance, and durability make them an excellent choice for structural components, cladding systems, windows, doors, curtain walls, and roofing systems. The use of aluminum ingots in construction not only enhances the overall aesthetics of the building but also contributes to its longevity, energy efficiency, and sustainability.

- Q: What is the difference between aluminium ingot and aluminium alloy ingot? Is the broken aluminium standard sold on the market now?

- Popular speaking, AOO aluminum ingot equivalent to raw materials, you can add silicon, copper and other ADC-12.AOO ingots are electrolytic aluminum, and ADC-12 is made from aluminum and other elements. Of course, the actual production is made of aluminum smelting.

Send your message to us

Aluminum Pig/Ingot Popular Sold 2015 With Best Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches