Aluminum Foil Tapes with Solvent Acrylic Adhesive T-F3004SP

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

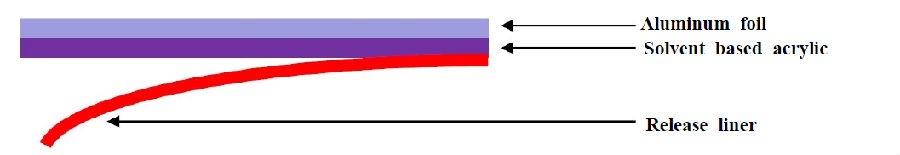

A aluminum foil with solventacrylic adhesive adhesive and protected byeasy release liner. Good for sealing joints / seams against moisture andvapor on foil jacketing insulation. Suitable for many other permanent sealing,holding, splicing or masking applications requiring the protection offered by afoil backing.

Product Construction

Carrier :Aluminumfoil,alloy: 8011 O

Adhesive glue: A high performance solvent acrylic adhesive.

Silicon paper: A white kraft paper, on aside laminated with film PE and coating solvent silicon. 75gram/sm.

TypicalPhysical Properties

PROPERTIES | UNITS | VALUE | TEST METHOD |

Backing Thickness | mm | 0.030 | PSTC-133 / ASTM D3652 |

Total Thickness | mm | 0.068 | PSTC-133 / ASTM D3652 |

Adhesion to Steel | N/25mm | ≥20 | PSTC-101/ ASTM D3330 |

Tack Rolling Ball | cm | 20 | PSTC-6 / ASTM D3121 |

Holding power | min | ≥1440 | PSTC-107/ASTM D3654 |

Tensile Strength | N/25mm | 45 | PSTC-131 / ASTM D3759 |

Elongation | % | 3.0 | PSTC-131 / ASTM D3759 |

Service Temperature | ℃ | -30~+120 | ———— |

Applying Temperature | ℃ | +10~+40 | ———— |

Product Form & SizeAvailable

Cut Roll: 48 / 50mm (2") / 60 / 63mm (2.5") / 72 / 75mm (3") / 96mm / 100mm(4").

Log Roll: 1020mmx 45 / 50m Jumbo Roll: 1020mm x 1200m / 1350m

Custom widths and lengths available, contact us forspecifications and requirements

Tolerance:Weight and Thickness: ±10%; Width: ±2mm; Length: Cut Roll: ±0.3m, Jumbo Roll ±0.5%.

The physical and performance propertiesshown are averages obtained from tests recommended by PSTC. A particular rollmay vary slightly from these averages and it is recommended that the buyerdetermine the suitability for his own purposes.

- Q: If I feel the room cool off, one hour hot and open an hour this will be more expensive? More

- No, polycyclic aromatic should be anthraquinone This is certainly not all of the hydrocarbons are carcinogenic

- Q: Air to water heater host and air conditioning host is not the same

- Issued a test report, Detection can be used to pass, failed to use!

- Q: US direct mail dysonhp01 Dyson air purification cooling machine triple in the country to warranty it

- Among them, the extruded polystyrene gypsum composite board is based on paper gypsum substrate, the use of adhesive and extruded polystyrene board through the factory processing compound

- Q: Gree air conditioning 50 heating and cooling mechanism heat when the host cooling network is how the matter

- Can be small, according to your roof to do what material.

- Q: Do 3cm thick wall insulation how much kilogram of slurry and how many kilograms of polystyrene particles

- You are talking about the construction measures it is not the house measures it, because the house has a construction of Huohuohuohuo number of leather and bronze sculpture drawings and specifications, high-rise building scaffolding should be lightning protection measures, that is, under the scaffolding around Reliable grounding (not less than four times, not less than 16 square copper core BV line), if it is pick plus, and the house can be connected to the pressure ring. Tower crane I will not say, upstairs has been said.

- Q: Air conditioning machine work when the sound is too much reason

- Color steel plate, refers to the color coated steel plate, color coated steel plate is a kind of organic coating with steel plate

- Q: What is the whole heat exchange fresh air ventilator?

- (GJG130 - Fan Jutang Duanjie Daojie Juejiao 2001) will be replaced by (GJG130-2011) is expected to begin the implementation of the construction of this year, the construction of fastener steel scaffolding safety technical specifications (GJG130), the construction of fastening steel pipe scaffolding safety technical specifications (GJG130- -2011)

- Q: Ventilation is very good, why still have to install fresh air system

- You are a single raft toilet wipes Pie Tanzhuang open card would like to confirm what? Contract notarization or. The The If it is contract notarized, generally notary value of 0.25% -0.3%

- Q: In the design, the building structure and the hydropower are generally designed by the Architectural Design Institute. The air conditioning ventilation is based on the design of the room. Or first air conditioning ventilation? More

- Normal heat absorption is also due to poor ventilation (dirty) and air humidity so icing

- Q: HVAC Heating: What are the main components of the air distribution system?

- The reasons are the following: 1. Household electricity is not enough, can not start the compressor, so in the heating state can only be ventilated state, cooling the state directly jump electricity; 2. See if you are reported failure, Code to determine the need for on-site inspection in order to know the specific situation; 3. Four-way valve should be no problem, do not just believe that this is the problem Oh; help your words to adopt

Send your message to us

Aluminum Foil Tapes with Solvent Acrylic Adhesive T-F3004SP

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords