Aluminum Foil Hoods Ventilation Duct Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 80000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

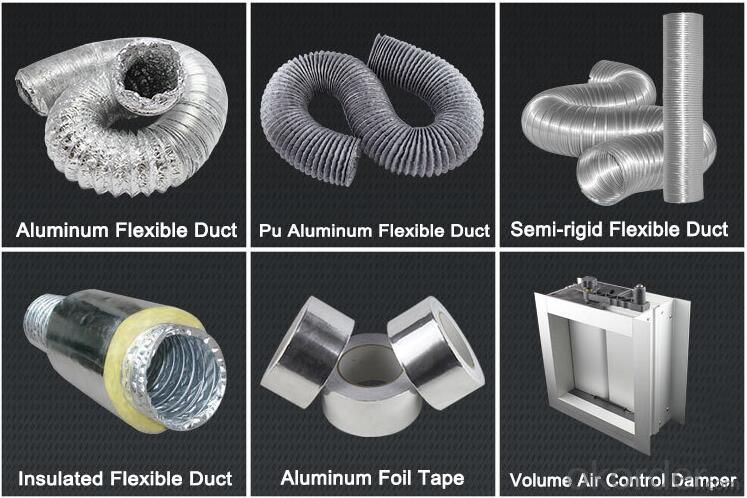

Aluminum Foil Hoods Ventilation Duct Pipe

Products description

ASI – Jacket (sleeve) 1 layer aluminum +1layer polyester +1helix steel wire +1 polyester

Insulation: Glass wool 25mm (thickness) 220g/m2

Inner Duct: aluminum + polyester

Application: ASI is a range of fully flexible insulated ducting. And provides outstanding resistance and durability, suitable for use with heating, ventilation and air conditioning systems.

Material of Duct | aluminum foil + pet + helix steel wire+ polyester |

Thickness of Inner Duct | 25 ~ 27 micron |

Fire Resistance | Limited combustibility |

Temperature Range | -30 °C/+150 °C |

Operating Pressure | 3000 Pa |

Maximum Air Velocity | 30 m/s |

Available Diameters | 50mm - 1200mm |

Available Inches | 3" - 20" |

Standard Length | 5m, 6m, 7.5m, 10m |

Packing | Cardboard box |

Features

1. Acoustic insulated duct made of aluminum foil + pet + helix steel wire+ polyester

2. Apply for low/medium/ high pressure, use for air ventilation in each environment.

3. Round style, and easy to install oval or round connection.

4. Fireproofing, at high temperatures or in case of fire, no toxic gas emitted.

5. Easy to delivery.

6. Good insulated---heat insulated

7. Absorb noise---can absorb the noise from the shaking when ventilated

8. No corrosive---not corrosive the aluminum pipe and metal parts

9. Durability---not decay, mildew

10. Fire---resistance

11. Practicality: suitable for the densely-populated area(such as school, supermarket, office, stadium, theater, factory.),high requirement of the environment area, such as hospital, laboratory, howff, bus, train, broadcasting studio.

Construction

Single layer aluminum flexible duct (AFD-S)

1) 1 layer of the aluminium laminated with the polyester with the coil made of the spring wire.

2) Total 2 layers: 1st layer: Aluminum foil ( 10um); 2nd layer: Polyester(15um)

3) Spring wire: carbon steel from 0.9~1.3mm

Multi layer aluminum flexible duct (AFD-D)

1) 2 layers of the aluminium laminated with the polyester with the coil made of the spring wire.

2) Total 3 layers: 1st layer: Aluminum foil ( 10um); 2nd layer: Polyester(15um); 3rd layer: Aluminum foil ( 10um)

spring wire: carbon steel from 0.9~1.3mm

FAQ

--Q: Can I get your latest products catalogue?

--A: Yes, it will be sent to you in no time.

--Q: What is the MOQ?

--A: 2 tons

--Q: What are your payment terms?

--A: We accept L/C, T/T.

--Q: What kinds of alloy can you supply?

--A: 1000 series: 1050, 1060, 1070, 1100, 1145,1200

3000 series: 3003, 3004, 3105, 3104

5000 series: 5052, 5083, 5754, 5182

6000 series: 6061, 6063, 6062, 6063

8000 series: 8011, 8021

--Q: What kinds of temper can you supply?

--A: O-H112: O,H12,H14,H16,H18,H22,H24,H26,H,32,H34,H111,H112

T3, T4, T6

- Q: What's the color strip in the tail of a cosmetic tube?

- Is the magic eye location, is used for positioning and recognition in the production of cosmetics products and sealing the electric eye positioning function is very common in printing packaging hose, hose product is produced after the completion of automatic filling and sealing machine location application.

- Q: What are the disposable medical plastic bags made of?

- Polyethylene (Polyethylene, PE), referred to as PE. It is a high molecular organic compound which is made up of ethylene. Polyethylene is recognized as the best food for contact with food in the world. Non-toxic, tasteless, odorless, in line with food packaging hygiene standards. Polyethylene film, light and transparent, with moisture-proof, anti - oxygen, acid, alkali, air tightness, heat sealing and other outstanding performance. Known as "plastic flower" laudatory title. It is the most important and most important material in plastic packaging and printing.

- Q: Accidentally put all the skin care products squeezed out, the kind of tubular packaging, and then I promptly put the skin care products sucked back, can I ask skin care products can still use it?

- This is also a lot of identity, it used in the face of things, try to pay attention to it, really spent, not money can cure the cream tube. Keep it as a hand cream.

- Q: CLARINS body shaping cream is bottle shaped or tubular packaging

- Maybe it has been changed. It's normal to change the packing, too. It's convenient to use tubular. Or go to the counter to see it, look at the counter, what is the sale now?

- Q: What's the advantage of plastic packing?

- ) small proportion, light weight. Although the proportion is less than that of other plastic packaging materials, but their strength / weight ratio is larger, making it possible to replace some larger strength materials, packaging container for manufacturing large load-bearing (such as a barrel, basket and box etc.). Packing materials and containers are small in proportion, which can save handling and transportation costs.

- Q: What kind of material are plastic bags made of?

- Polyethylene (Polyethylene, PE), referred to as PE. It is a high molecular organic compound which is made up of ethylene. Polyethylene is recognized as the best food for contact with food in the world. Non-toxic, tasteless, odorless, in line with food packaging hygiene standards. Polyethylene film, light and transparent, with moisture-proof, anti - oxygen, acid, alkali, air tightness, heat sealing and other outstanding performance. Known as "plastic flowers" laudatory title. It is the most important and most important material in plastic packaging and printing.

Send your message to us

Aluminum Foil Hoods Ventilation Duct Pipe

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 80000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords