Aluminium Sulphate No Iron From China Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Chemical and Physical Properties:

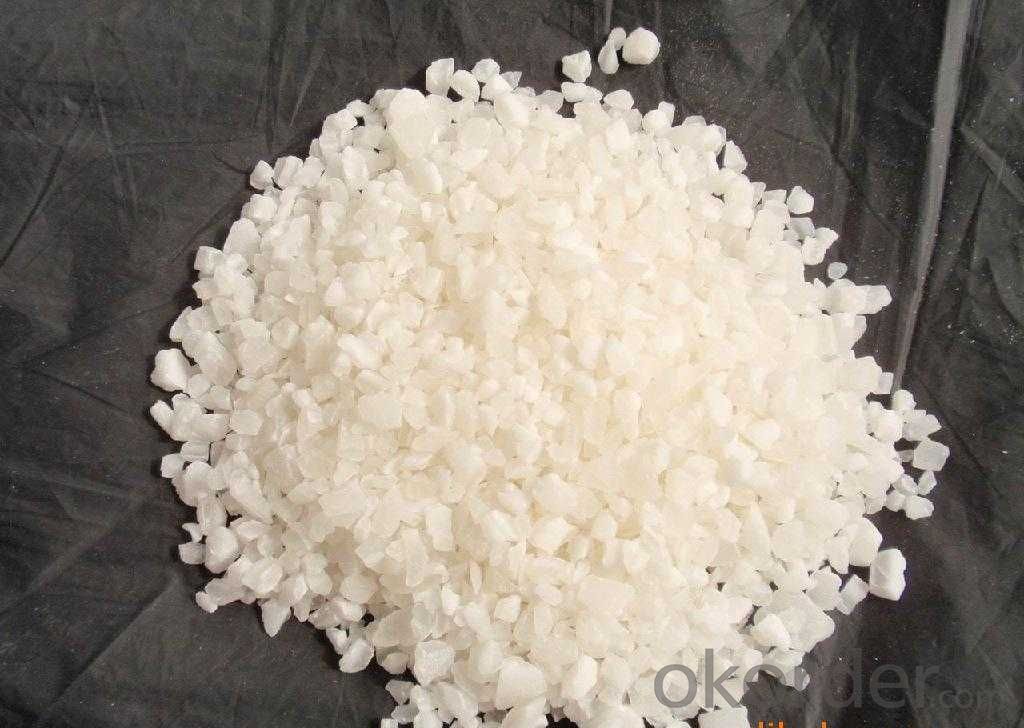

Product name: Aluminium Sulphate or Aluminum Sulfate

Shape: Flakes or Granular or Powder.

EINECS NO.:233-135-0

CAS No.: 10043-01-3

HS.Code: 28332200

Molecular Formula: Al2(SO4)3

Appearance:It is white or grey flake,particle or massive crystallization.

Apt to cake after moisture absorption when laid in air for a long time.A little green because of Fe2+ ,yellow when Fe2+ is oxided to Fe3+.Soluble in water easily,and water solution is acid.

2. Specification:

Standard: HG/T 2225-2001 and HG/T 2227-2004

Items | Specifications | |||

I Type:Low Ferrous/Low Iron | II Type:Non-Ferrous/Iron-free | |||

First Class | Qualified | First Class | Qualified | |

Al2O3 % ≥ | 15.8 | 15.6 | 17 | 16 |

Ferrous(Fe )% ≤ | 0.5 | 0.7 | 0.005 | 0.01 |

Water Insolube % ≤ | 0.1 | 0.15 | 0.1 | 0.15 |

PH (1% aqueous solution) ≥ | 3.0 | 3.0 | 3.0 | 3.0 |

Arsenic(As) %≤ | 0.0005 | 0.0005 | ||

Heavy metal (Pb) %≤ | 0.002 | 0.002 | ||

3.Applications:

Water effluent treatment system

It's used for purification of drinking water and wastewater treatment by settling of impurities by

means of precipitation and flocculation.

Paper Industry

It helps in sizing of paper at neutral and alkaline pH, thus improving paper quality (reducing spots

and holes and improving sheet formation and strength) and sizing efficiency.

Textile Industry

It is used for color fixing in Naphthol based dyes for cotton fabric.

Other Uses

Leather tanning, lubricating compositions, fire retardants; decolorizing agent in petroleum, deodorizer; food additive; firming agent; dyeing mordant; foaming agent in firefighting foams; fireproofing cloth; catalyst; pH control; waterproofing concrete; aluminum compounds, zeolites etc.

4. Package:

Packaging Detail: PP/PE 50kg/bag;25kg/bag;Jumbo bag or according to customers' requirements.

20-25MT will be loaded in per 20'FCL container.

5. Attention and Storage:

The product is liable to absorb moisture and clot due to long-term exposure, so shady, cool and ventilated environment is needed.

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: Is the catalyst considered a chemical reaction?

- The middle school textbook defines that the catalyst itself does not participate in chemical reactions

- Q: Chemical production of iodine and magnesium with water as catalyst!

- In the 250mL three bottles were equipped with spherical condenser and constant pressure dropping funnel, in the condensate tube connected to the anhydrous calcium chloride drying tube. The flask was placed with 1.5 g of magnesium chip and a small tablet of iodine, 10 g of bromobenzene and 30 mL of anhydrous ether were mixed in a constant pressure dropping funnel. First 1/4 of the mixture into the flask, a few minutes later see the magnesium surface of the bubble generated, the solution was slightly cloudy, iodine color began to disappear. If no reaction occurs, use a hot water bath. After the start of the reaction, stir, slowly dropping the remaining bromophene ether solution, dropping the rate to keep the solution was slightly boiling state, after adding, in the water bath to continue reflow 0.5h, magnesium tablets full effect.

- Q: what is metallocene catalyst technology?

- Metallocene catalyst A transition-metal atom sandwiched between ring structures having a well-defined single catalytic site and well-understood molecular structure used to produce uniform polyolefins with unique structures and physical properties. See also Catalysis; Coordination chemistry; Coordination complexes; Metallocenes; Organometallic compound. In the early 1980s, W. Kaminsky discovered that an appropriate co-catalyst activated metallocene compounds of group 4 metals, that is, titanium, zirconium, and hafnium, for alpha-olefin polymerization, attracting industrial interest. This observation led to the synthesis of a great number of metallocene compounds for the production of polymers already made industrially, such as polyethylene and polypropylene, and new materials. Polymers produced with metallocene catalysts represent a small fraction of the entire polyolefin market, but experts agree that such a fraction will increase rapidly in the future. See also Polymer; Polymerization; Polyolefin resins.

- Q: Chemistry why the catalyst can be equal to speed up the positive reaction rate

- Since the catalyst only changes the activation energy and the amount of reactivity can be reduced, the amount of reaction energy is also reduced. Therefore, a positive catalyst is also a good catalyst for its reaction. Speed up the same multiple.

- Q: Chemical equation if there is a catalyst and heating, which write in the equal sign above, which written in the following? Tomorrow academic level test, solution

- At the same time, the catalyst is written on, and the heating symbol is written under the equal sign. Only one is written on the equal sign

- Q: Who knows hydrogen and nitrogen in the high temperature, high pressure and catalyst conditions for the synthesis of ammonia chemical equation ah? Urgent! The SOS

- 3H2 + N2 ===== 2NH3 conditional catalyst

- Q: Explain how a catalyst may increase the rate of chemical reaction?

- A catalyst speeds up the reaction by lowering the energy needed for a reaction to occur.

- Q: How are a catalyst and an intermediate similar? How are they different?

- A catalyst speeds up the rate of a reaction by lowering the activation energy barrier which is, presumably, the energy required to achieve the reaction intermediate. Catalysts are also not consumed in the reaction, they are regenerated towards the end. A reaction intermediate is a configuration that a molecule takes prior to achieving it's lowest energy form which would signify the end of the reaction. Intermediate usually are hard to isolate because of the incentive to go to the most stable configuration. How are they different? A catalyst is not a part of the reaction product and it doesn't get consumed. An intermediate in a reaction is transformed into the product. How are they similar? Well, catalysts drive the reaction and make it easier for the reaction for follow through. Since intermediates are high energy and thermodynamics tells us that low energy is favorable, the incentive for a high energy intermediate to drive down to it's stable for can also drive a reaction. I hope that helps. I hope it makes sense.

- Q: What is the relationship between the catalyst and the chemical reaction? What is the relationship between the enzyme and the catalyst?

- Catalytic, also known as catalyst, is defined in the junior high school stage to be able to change the rate of chemical reactions, and its own quality, composition and chemical properties remain constant before and after chemical reactions. For example, manganese dioxide can be used as hydrogen peroxide (hydrogen peroxide) decomposition of the catalyst. The catalyst is divided into the positive catalyst and the catalyst is used. The positive catalyst contributes to the reaction to move in the positive direction, and the reverse catalyst contributes to the reaction to move in the reverse direction.

- Q: Can the catalyst be a reactant in chemistry?

- There is also a saying that the catalyst participates in the chemical reaction. In a general chemical reaction, the effect of the catalyst is to reduce the activation energy required for the reaction to occur, essentially to turn a more difficult reaction into two, In the second reaction, the catalyst in the first reaction plays the role of the reactant, and the catalyst in the second reaction plays the role of the product, so that the catalyst is not present before and after the reaction Variety.

Send your message to us

Aluminium Sulphate No Iron From China Manufacturer

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 12000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords